Inspection device for automobile catalyst converter assembly

A technology for automotive catalytic converters and assemblies, which is applied in the direction of instruments, measuring devices, and mechanical devices, etc., can solve the problems of inability to locate and detect, and cannot accurately detect the total length of the automotive catalytic converter assembly, so as to improve accuracy and speed The effect of accurate positioning detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

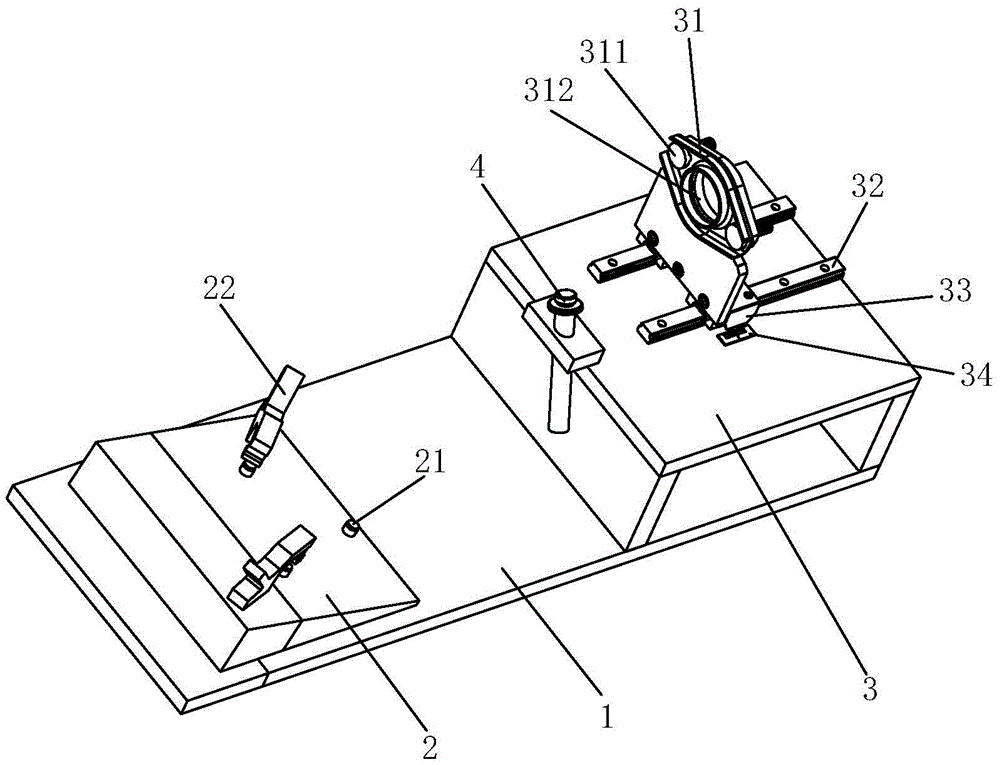

[0018] An automobile catalytic converter assembly inspection tool, comprising a bottom plate 1, a three-hole bottom plate positioning plate 2, a positioning pin 4 and a flange positioning device 3, the three-hole bottom plate positioning plate 2, a positioning pin 4 and a flange positioning device 3 They are all arranged on the bottom plate 1, and the three-hole bottom plate positioning plate 2 is arranged on the bottom plate 1 in an inclined manner, and the three-hole bottom plate positioning plate 2 is provided with three bolt holes on the bottom plate of the automobile catalytic converter assembly. The corresponding three positioning pins 21, that is, the positioning pins 21 are protruding shafts that can be inserted into the bolt holes. The three-hole floor positioning plate 2 is also provided with a clamping piece 22 for clamping the bottom plate of the automobile catalytic converter assembly. The clamping piece 22 is arranged on the three-hole bottom plate positioning pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com