Inspection device for automobile catalyst converter assembly

A technology for automotive catalytic converters and assemblies, which is applied in the direction of instruments, measuring devices, and mechanical devices, can solve the problems of inability to locate and detect the total length of the automotive catalytic converter assembly, and achieve rapid and accurate positioning and detection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

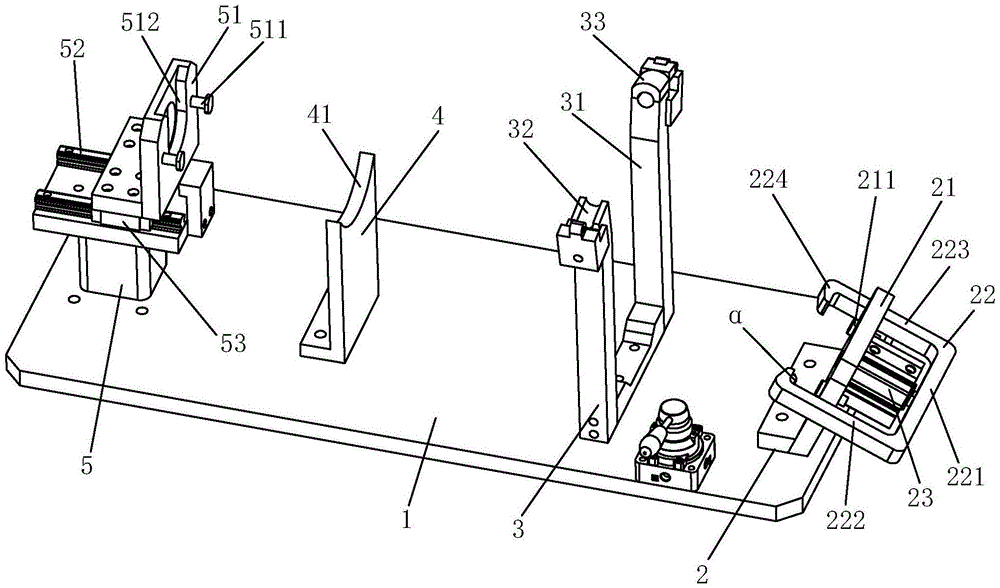

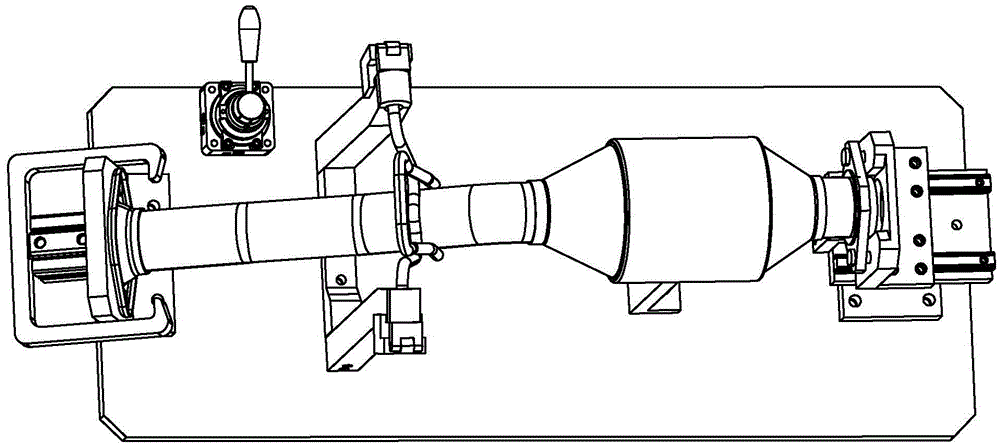

[0020] An automobile catalytic converter assembly inspection tool, comprising a base plate 1, an air intake flange detection device 2, a hook detection device 3, a cylinder positioning plate 4 and an air outlet flange detection device 5, the air intake flange detection device 2 , the hook detection device 3 and the air outlet flange detection device 5 are all arranged on the base plate 1, and the air inlet flange detection device 2 and the air outlet flange detection device 5 are respectively arranged at the two ends of the base plate 1, and the hanger The hook detection device 3 includes two hook positioning detection frames 31, the two hook positioning detection frames 31 are respectively arranged on both sides of the base plate 1 opposite to each other, and the cylinder positioning plate 4 is provided with a cylinder positioning groove 41 , the barrel positioning plate 4 is fixedly arranged on the bottom plate 1 and is located between the hook detection device 3 and the air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com