Defective lens disassembling structure and using method thereof

A lens and bad technology, applied in the direction of installation, optics, instruments, etc., can solve the problems of damage, electric soldering iron hard, difficult to cut, etc., achieve the effect of low lens damage rate, solve the problem of lens scrapping, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

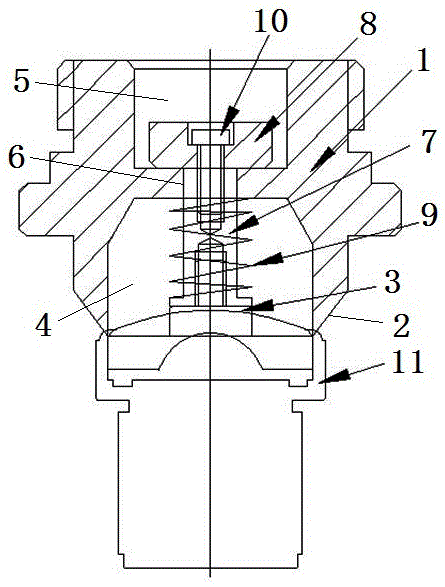

[0020] like figure 1 As shown, a defective lens dismantling structure includes a dismantling head 1 for cutting off the fused surface of the lens and the lens barrel, the end of the dismantling head is a sharp wedge-shaped surface 2, and the dismantling head A pressing block 3 for pressing the lens is arranged inside, and the movement between the pressing block and the dismantling head is driven by an elastic element to reciprocate and squeeze the lens vertically.

[0021] In this embodiment, the inner bottom of the disassembly head is provided with a cavity A4 for accommodating the briquetting block, the inner top of the disassembly head is provided with a cavity B5, and the cavity A and the cavity B are A cylindrical port 6 extending vertically is provided.

[0022] In this embodiment, a guide rod 7 for vertically sliding on the cylindrical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com