Steel wire rope rotation preventing device applied to container crane

A container crane and wire rope technology, applied in the direction of hoisting device, spring mechanism, etc., can solve the problems of frequent hoisting rope head swing, high maintenance cost, increased downtime, etc., achieving obvious anti-rotation effect and easy maintenance. , the effect of simplifying the organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] For the purpose of full disclosure, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described below are only used for explaining the present invention, but not for limiting the protection scope of the present invention.

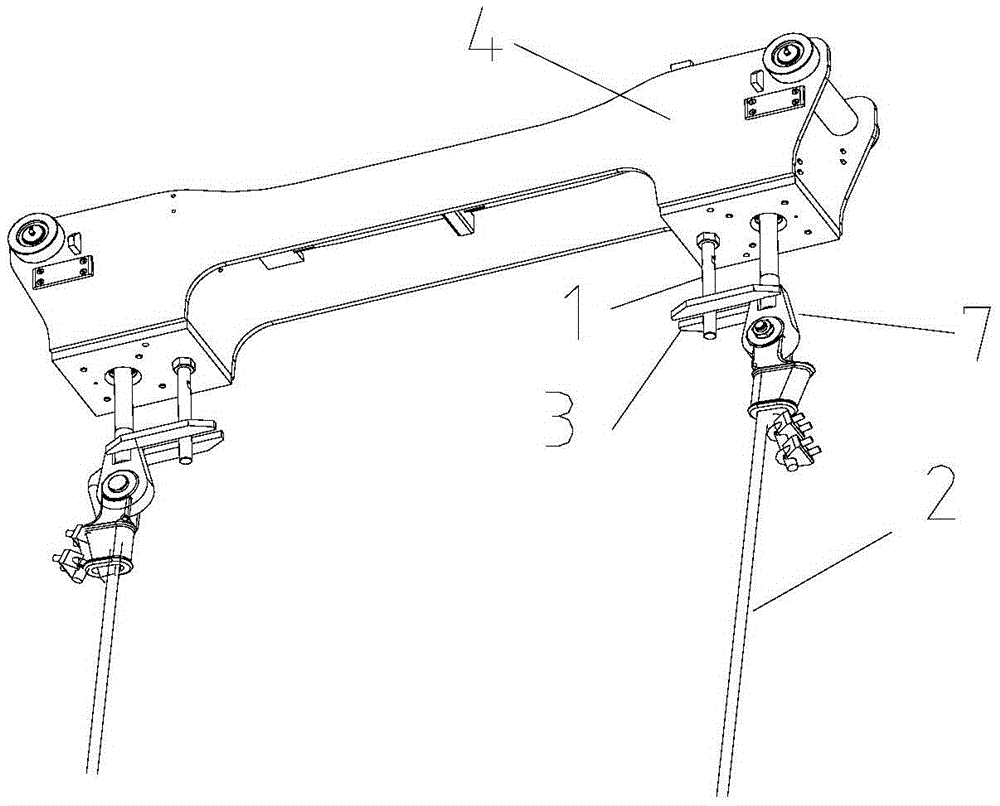

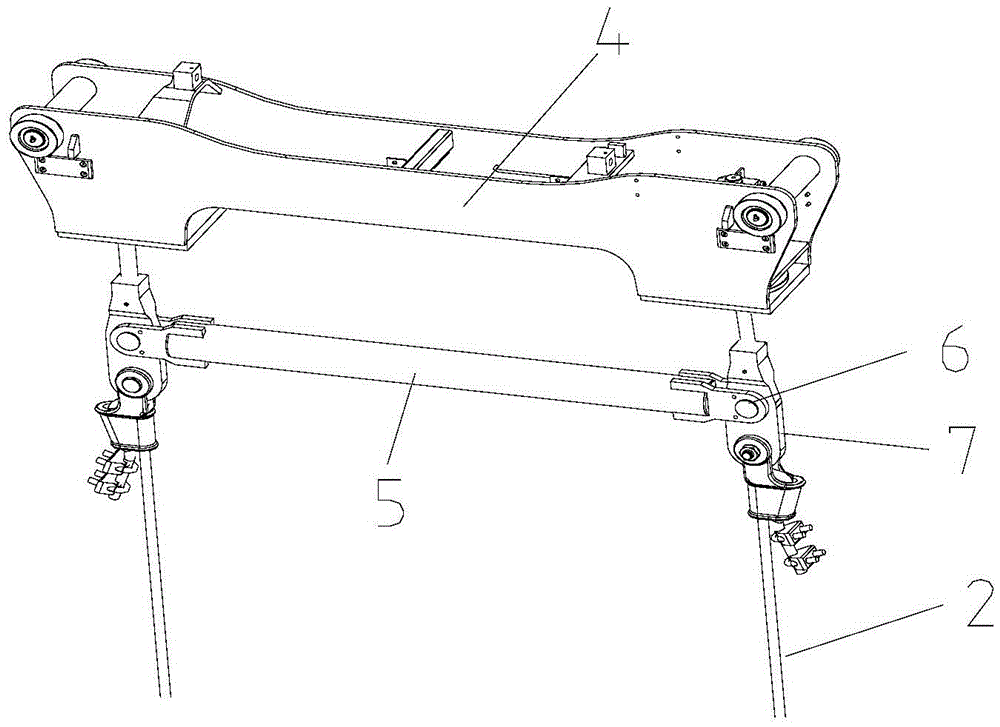

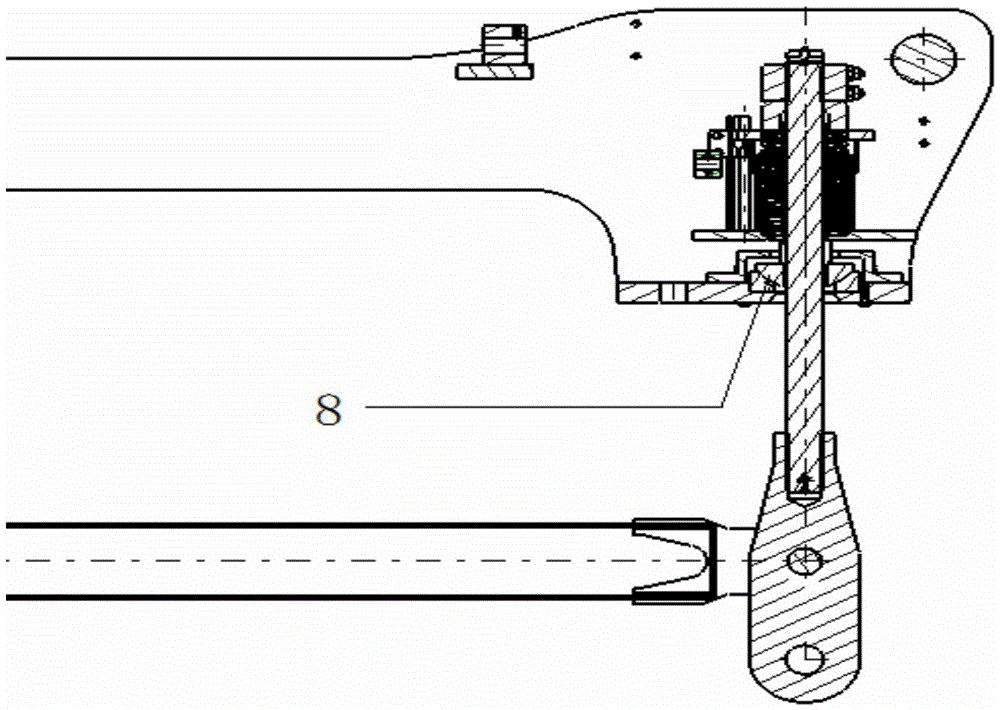

[0024] like figure 1 As shown, in the prior art, the problem of preventing the rotation of the four hoisting rope heads is independently solved by the setting of the fixed rod 1 and the limit fork 3 on each steel wire rope 2, but due to the high working level of the rubber-tyred container crane, the load The weight is heavy, the hoisting rope head swings frequently and moves irregularly, the wear between the anti-rotation limit fork 3 and the fixing rod 1 is serious, and regular inspection and replacement is required, which is high maintenance cost and increases the downtime. If the fork is broken, the crane will have a gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com