Fire ventilation pipe valve

A technology for ventilation pipes and valves, which can be applied to lift valves, valve devices, engine components, etc., can solve problems such as increased manufacturing costs, increased valve weight, and limited effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

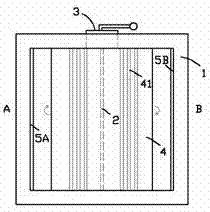

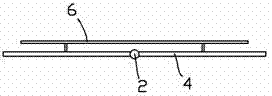

[0014] The basic part of the fire ventilation pipe valve is consistent with ordinary valves, such as figure 1 shown, including the short tube (extending inward from the paper, figure 1 blocked by the connecting flange), and the connecting flanges 1 at the front and rear ends of the short pipe; the short pipe is provided with a vertical rotating shaft 2, and the rotation of the rotating shaft 2 is controlled by the operating mechanism 3 outside the short pipe; the rotating shaft 2 is fixed with a vertical valve plate 4 that is symmetrical about the rotation axis; a vertical reinforcement groove 41 is formed on the valve plate 4; sealing edges matching the left and right sides of the valve plate 4 are also provided in the short pipe Bars 5A, 5B, the valve plate 4 is rotating with the rotating shaft 2; figure 1 In the paper, the outside of the paper is set as the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com