Fuel tank apparatus of scooter type motorcycle

A scooter type, fuel tank technology, applied in gasoline drums, bicycle accessories, transportation and packaging, etc., can solve the problems of high center of gravity, inability to increase the size of the fuel tank, and inconvenient riding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

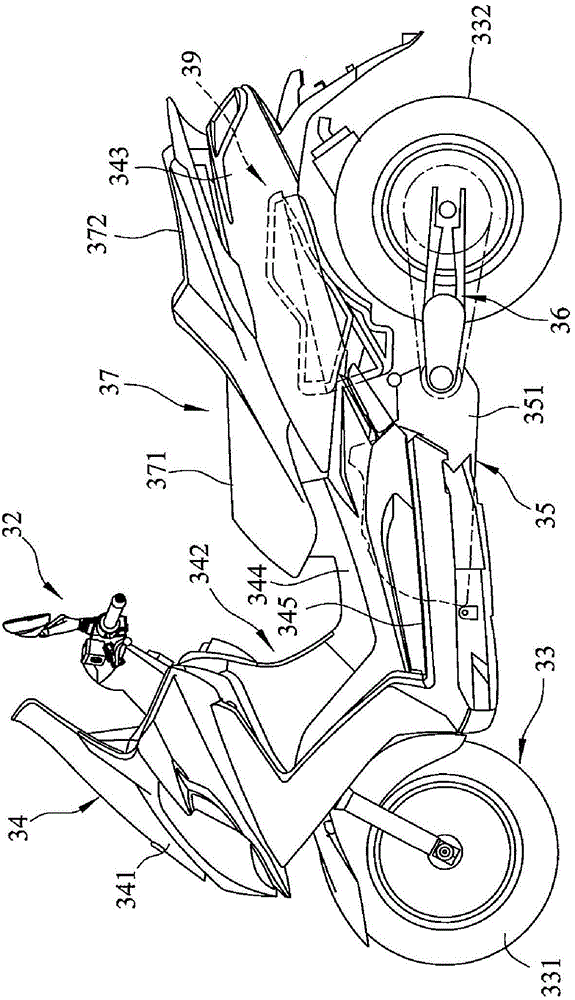

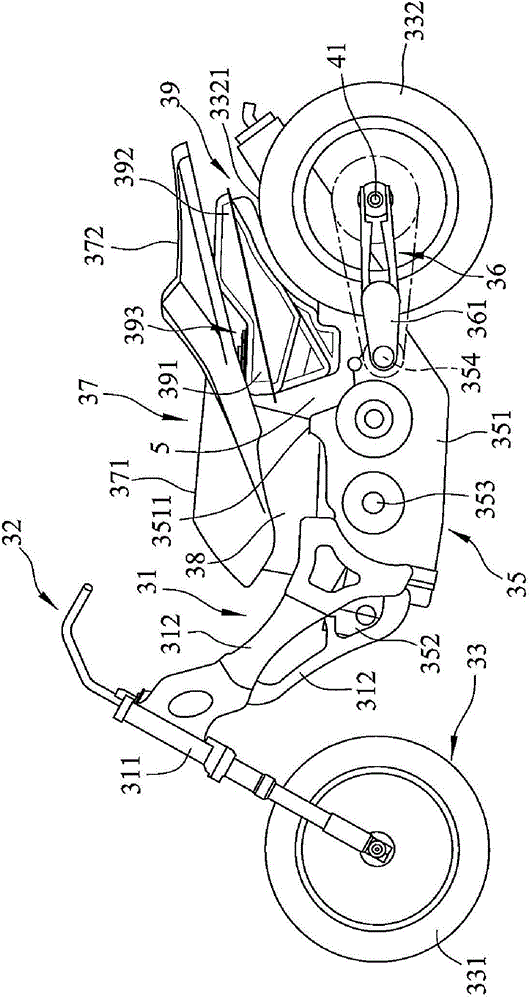

[0013] refer to figure 2 , 3 , is an embodiment of the fuel tank configuration (structure) of the scooter type motorcycle of the present invention, and the scooter type motorcycle includes a frame unit 31, a handle unit 32, a wheel unit 33, a A car shell unit 34 outside the frame unit 31, an engine unit 35 arranged on the vehicle frame unit 31, a rear rocker arm unit 36, a seat cushion 37 pivotally arranged on the vehicle frame unit 31 and available for riding, a A storage box 38 and a fuel tank 39 are disposed on the frame unit 31 .

[0014] The frame unit 31 includes a head tube 311, two descending arms 312 connected to the head tube 311 at intervals and extending obliquely downward, and a rear end connecting the two descending arms 312 and extending away from the head tube 311. frame (not shown). The handle unit 32 is connected to the upper end of the head pipe 311 so as to be rotatable left and right. The wheel unit 33 includes a front wheel 331 connected to the lower...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap