Automatic glue spraying and sealing mechanism for OPP packaging bags

A packaging bag and glue spraying technology, which is applied in the directions of packaging sealing/fastening, packaging, transportation packaging, etc., to achieve the effects of firm sealing, improved economic benefits, and uniform glue spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

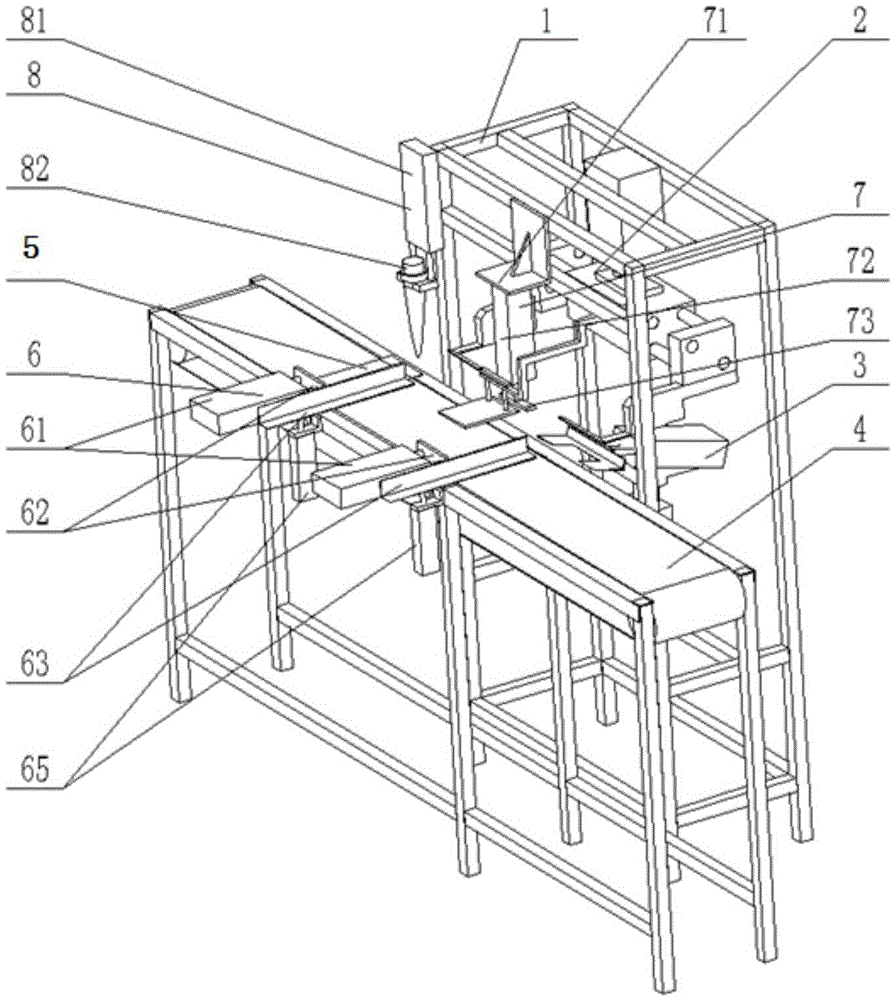

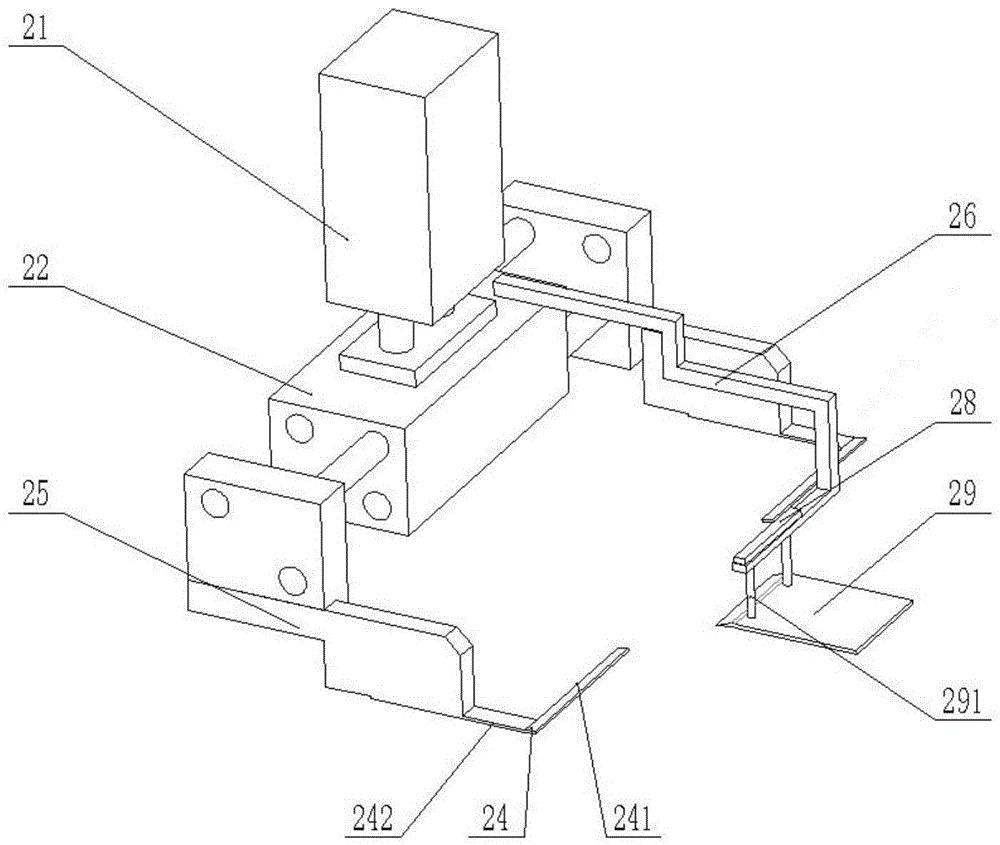

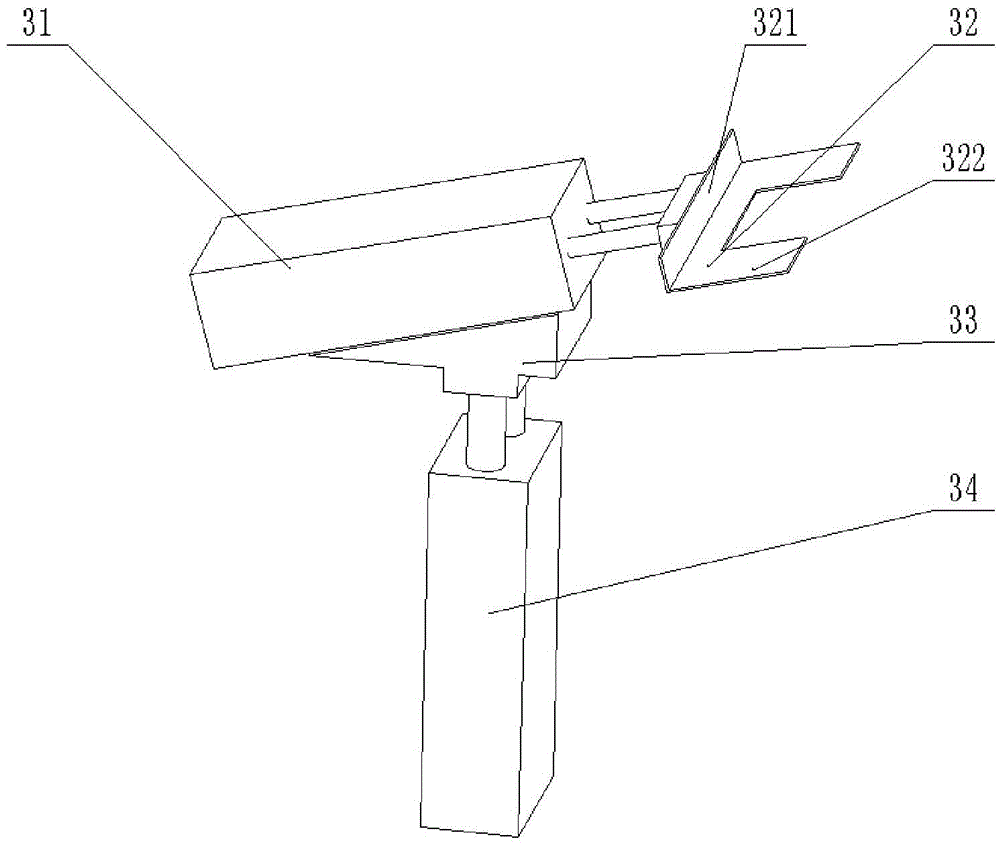

[0033]A kind of automatic glue spray sealing mechanism (see Figure 1-3 ), including a pressing device 2, a sealing device 3, a positioning device 6, a glue spraying device 8, a pressing device 7, a transmission device 4 and a frame body 1 for installing the above devices, and the transmission device is horizontally installed on the frame body For the conveyor belt on the top, take the conveying direction of the conveyor belt as the vertical axis, that is, the y-axis, and take the horizontal direction perpendicular to the longitudinal direction as the horizontal axis, that is, the x-axis, and take the conveying direction as the positive direction to determine the positive and negative directions of the y-axis.

[0034] The glue spraying device, the pressing device, the sealing device, and the pressing device are installed on the frame above the same side of the transmission belt, and the side of the transmission belt is the installation side, and the opposite side of the instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com