Pneumatic tire

A technology of pneumatic tires and tires, which is applied in the field of tread patterns, can solve the problems that the shared force cannot contribute to it, large lateral grip, etc., and achieve the effect of improving turning performance and increasing lateral grip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

comparative test 1

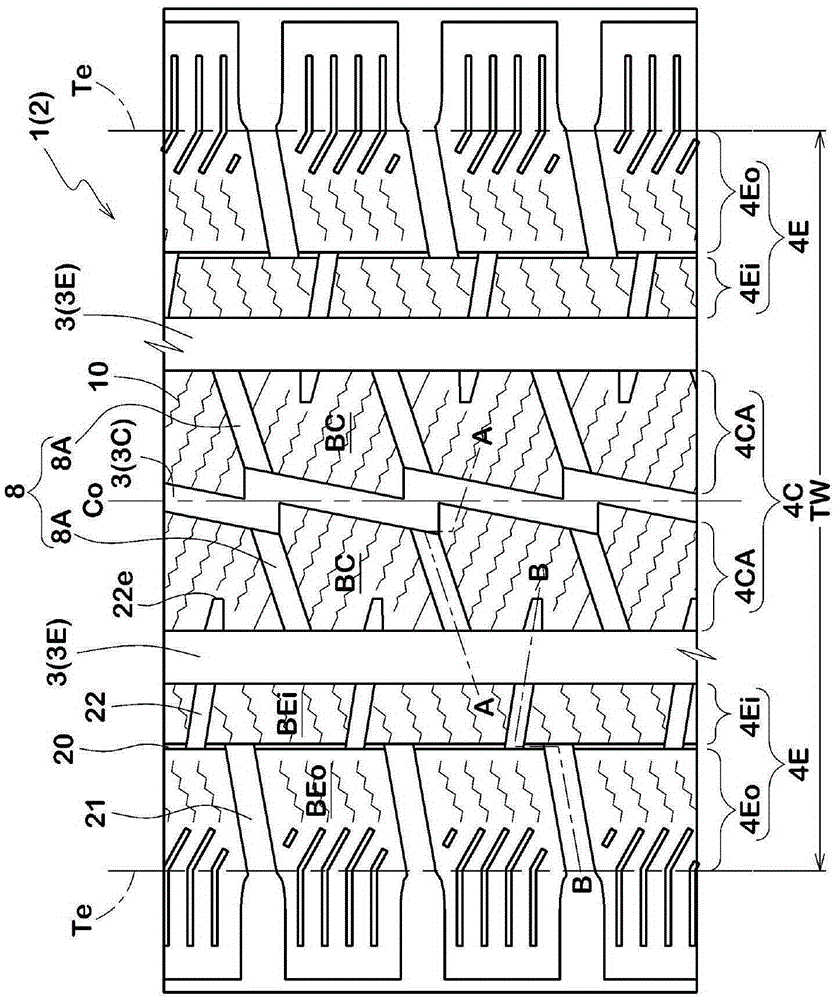

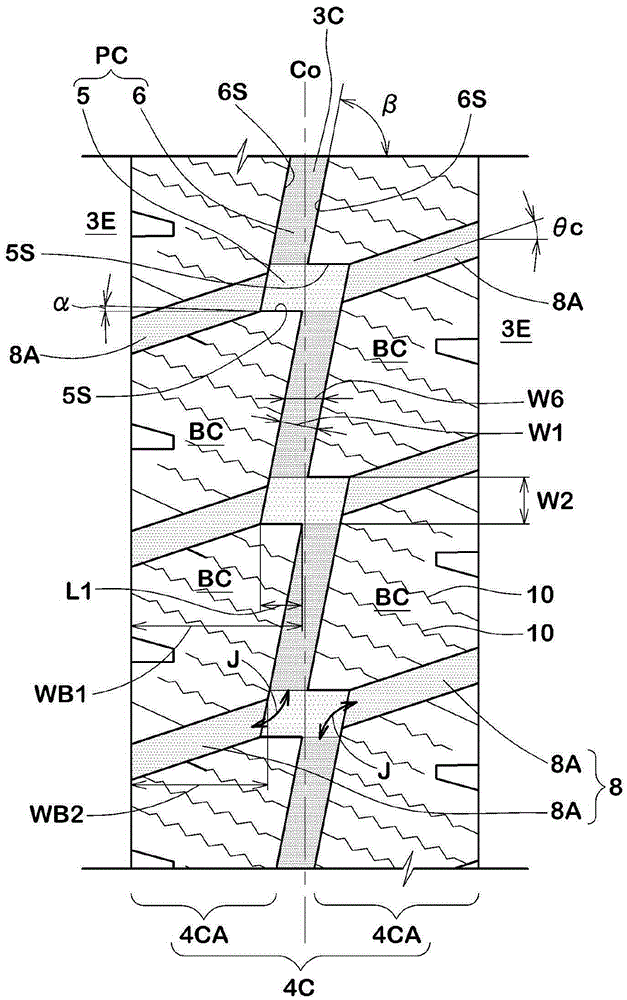

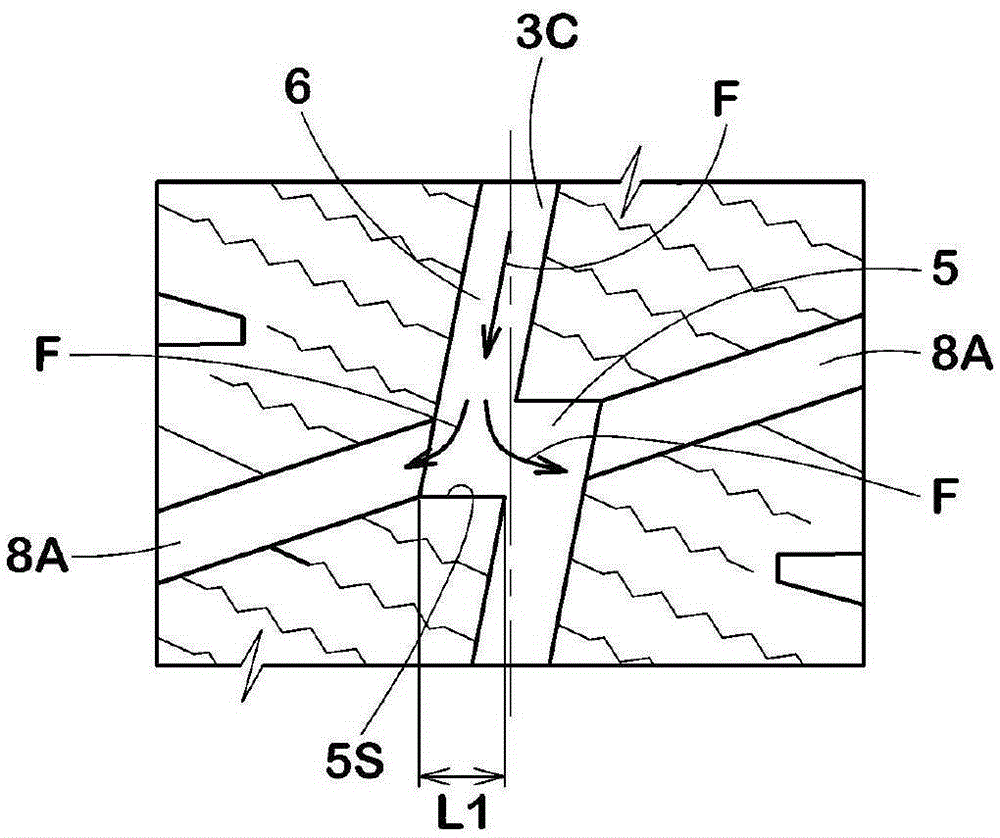

[0129] based on figure 1 The tread pattern shown in is experimentally manufactured for a studless anti-skid tire with a size of 205 / 65R16 (rim size 16×6.5J). The specifications of grooves, crown oblique grooves, central circumferential main grooves and sipe are changed to those listed in Table 1. Additionally, all tires have substantially the same specifications.

[0130] The tires were tested for snow performance and abrasion resistance as follows.

[0131] (Turning performance on snow)

[0132] The test tires are installed on all four wheels of a medium-sized truck (engine displacement 2800cc, front tire pressure 390kPa, rear tire pressure 350kPa, load 50% of the maximum load), and the test driver is on the snow-covered road at the tire test site Lateral grip during driving was evaluated. In Table 1, the results are represented by an index based on the comparative example tire ReF.1 (which is 100), wherein the larger the index, the greater the lateral grip, ie, the bette...

comparative test 2

[0136] based on figure 1 The tread pattern shown in , was experimentally manufactured for a studless tire with a size of 205 / 65R16 (rim size 16×6.5J), and the specifications of the central circumferential main groove, crown oblique groove and slit were changed for the specifications listed in Table 2. Additionally, all tires have substantially the same specifications.

[0137] The tires were tested for snow performance as above and wet performance as below. Table 2 shows the results of the snow performance test.

[0138] (wet performance)

[0139] Using the test vehicle described above, the test driver evaluated the steering stability during running on the wet road surface of the tire test field. In Table 2, the results are represented by indices based on Comparative Example tire ReF.A1 (which is 100), wherein the larger the index, the better the wet performance.

[0140] As shown in Tables 1 and 2, the cornering performance of the working example tires on snow was improv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com