Film sticking device

A technology of film sticking device and film sticking mechanism, which is applied in the directions of packaging, package protection, transportation and packaging, etc., can solve the problems of low efficiency, achieve fast film sticking, and improve the effect of film sticking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

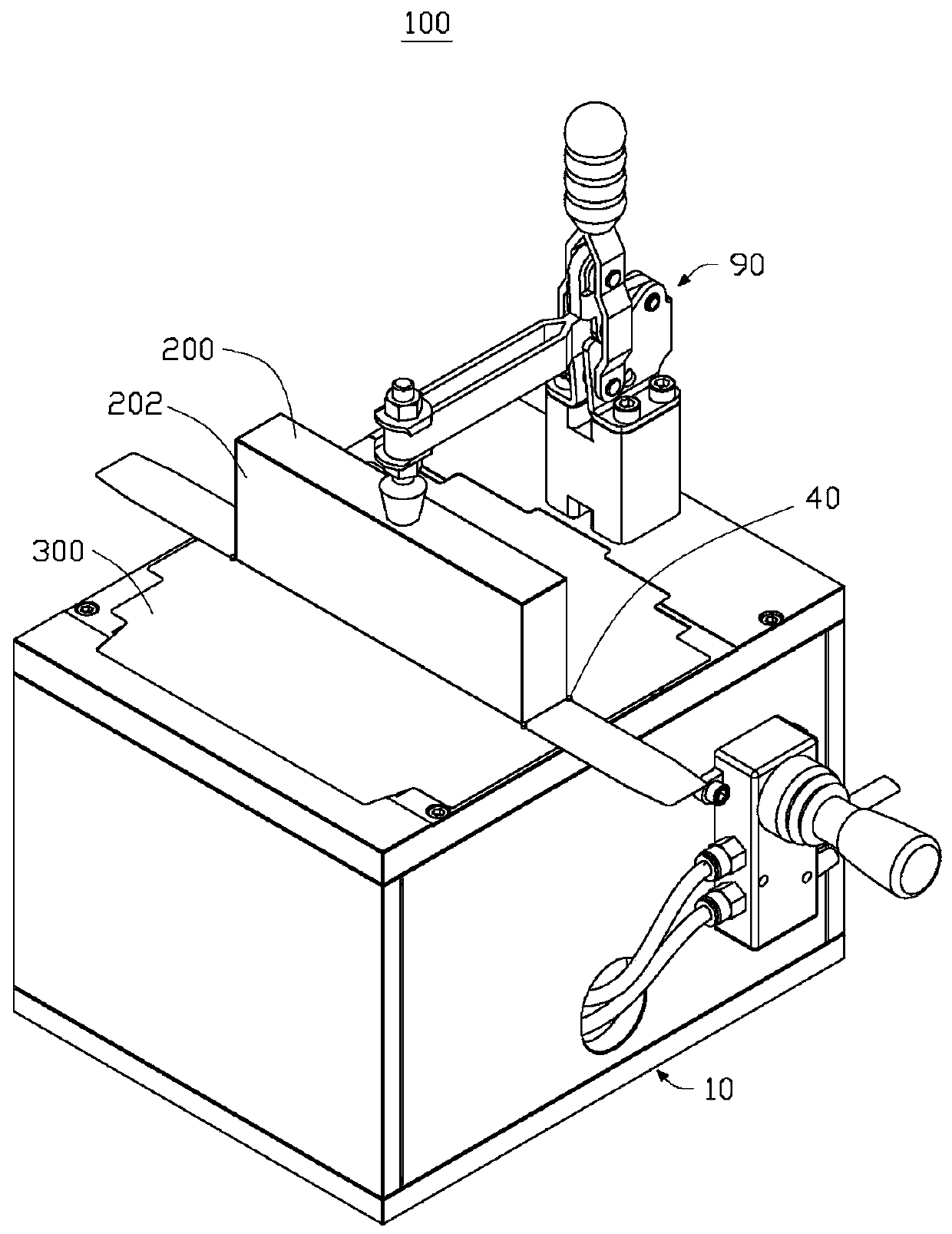

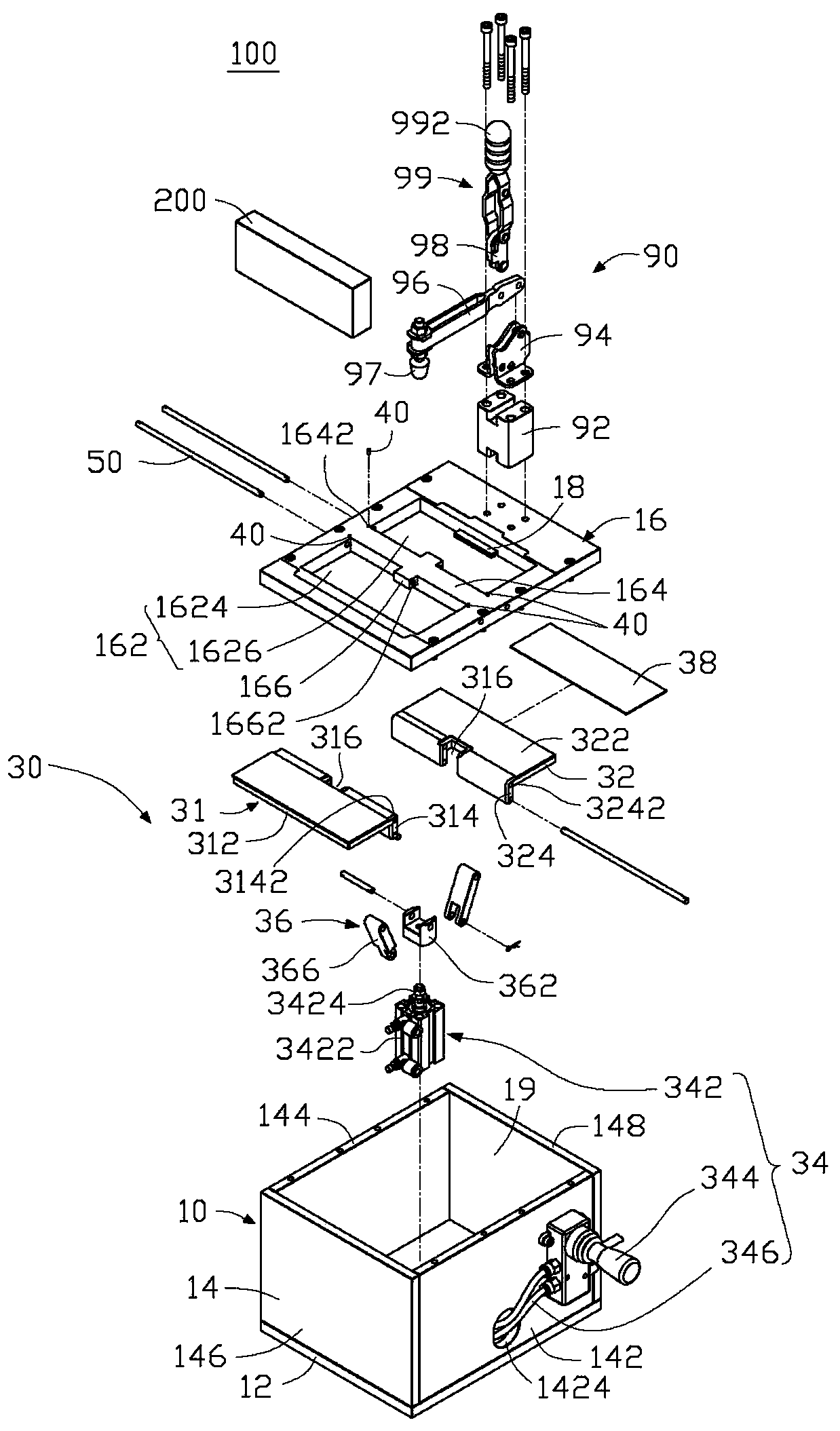

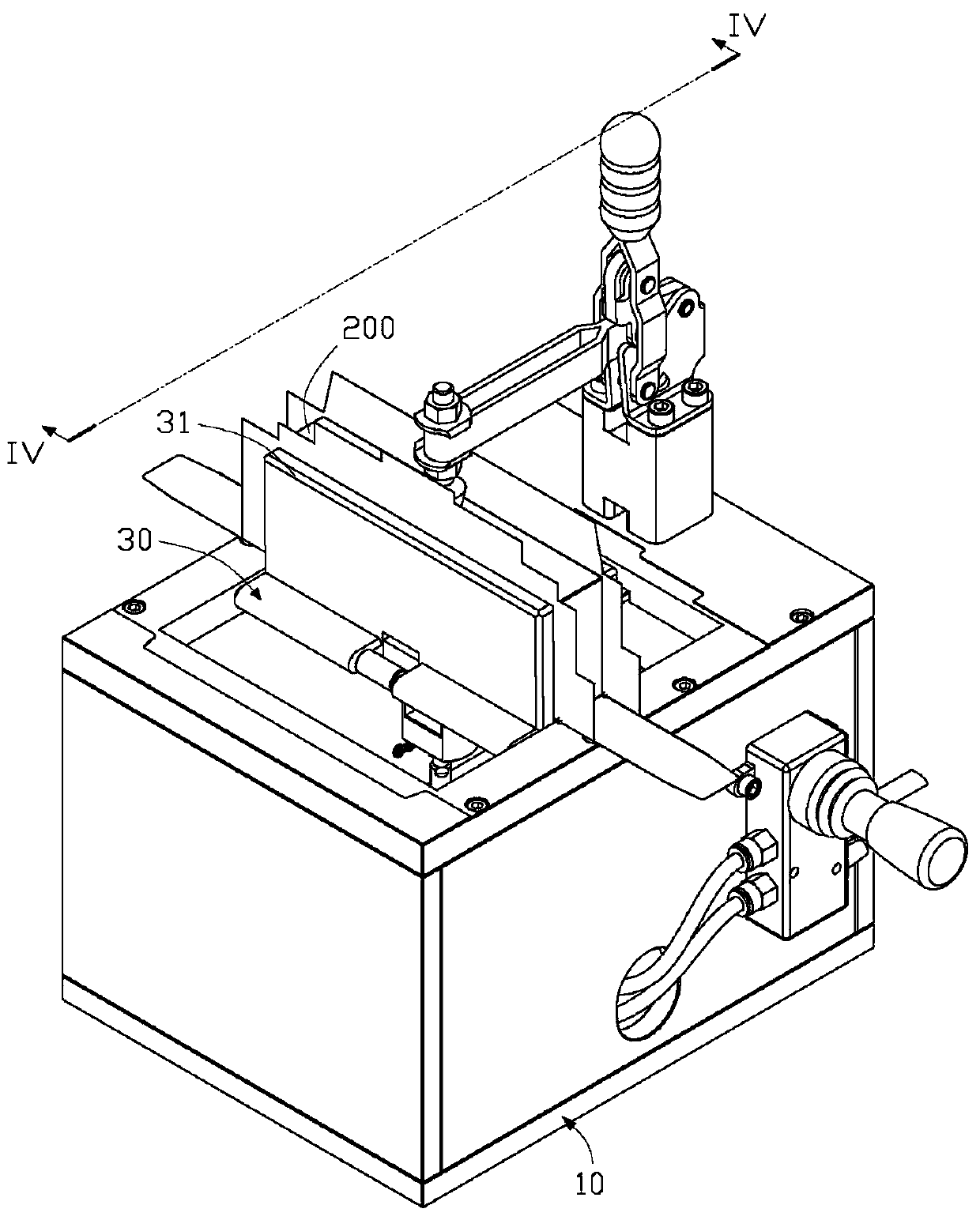

[0063] see figure 1 , this embodiment provides a film sticking device 100 for sticking a film material 300 on a workpiece 200 . In this embodiment, the workpiece 200 is in the shape of a regular hexahedron, and the workpiece 200 has two opposite sides 202 .

[0064] see figure 1 and figure 2 , the film sticking device 100 includes a base 10 and a film sticking mechanism 30 disposed on the base 10 .

[0065] see again figure 2 , the base 10 is in the shape of a rectangular parallelepiped box, which includes a bottom plate 12 , a plurality of side plates 14 and a top plate 16 arranged around the periphery of the bottom plate 12 . The bottom panel 12 , the side panels 14 and the top panel 16 together define a receiving space 19 . In this embodiment, the bottom plate 12 is substantially rectangular plate-shaped. The number of side plates 14 is four, which include a first side plate 142 and a second side plate 144 which are substantially parallel to each other, and a third ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com