Arrangement for connecting components

A technology for parts and heads, applied in the field of devices for connecting parts, can solve problems such as difficulty in establishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

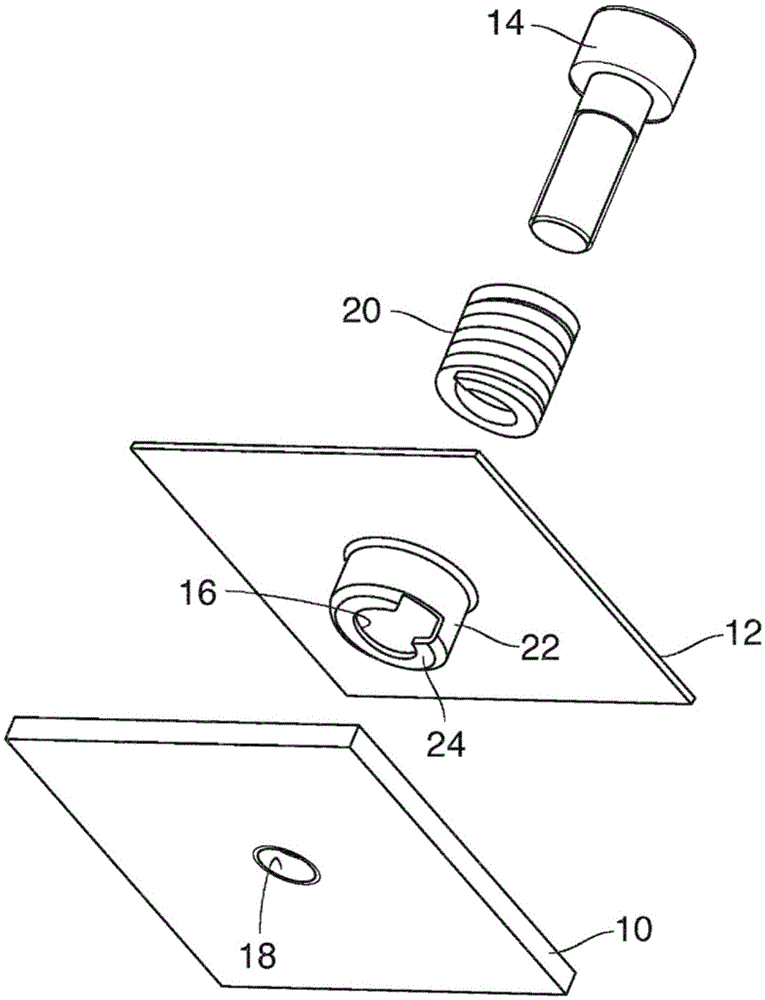

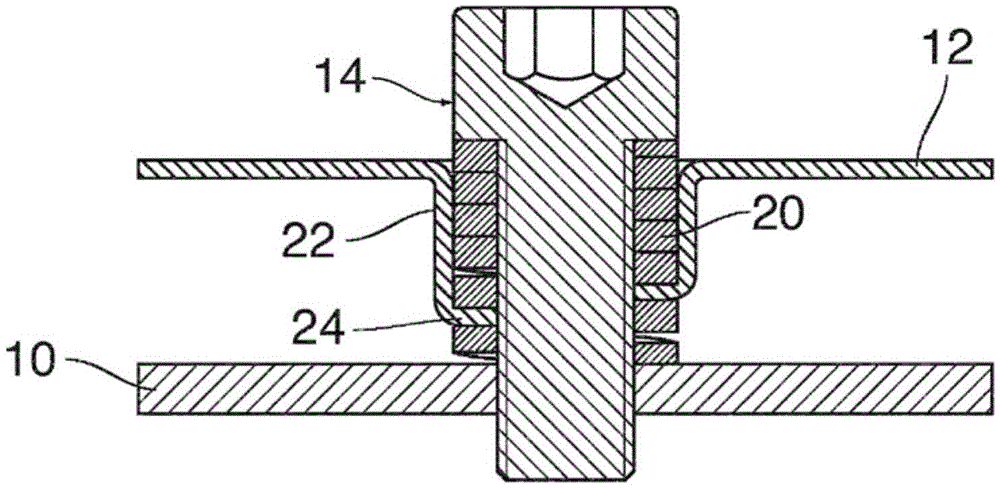

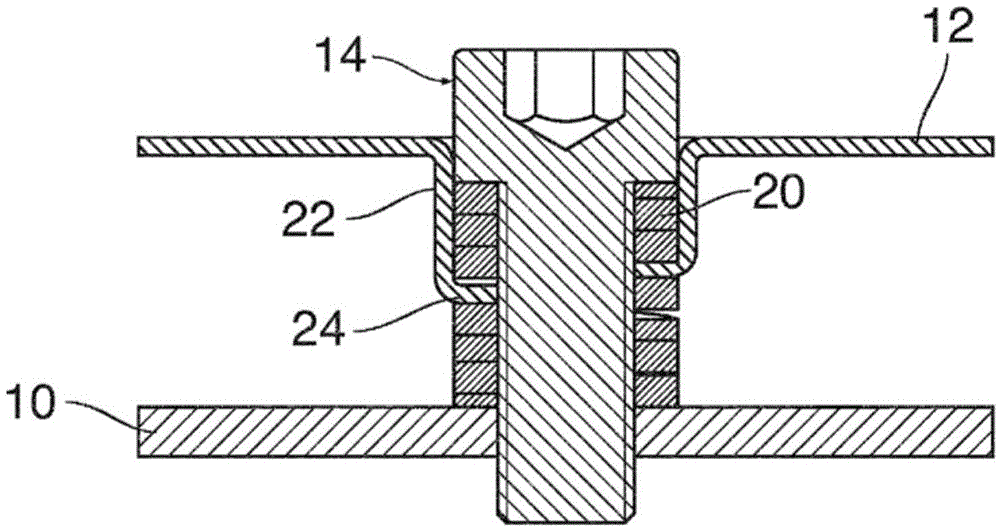

[0028] figure 1 A connecting device is shown for connecting the first part 10 to the plate-shaped second part 12 (for example, sheet metal) while being spaced apart. To this end, a screw 14 is provided, which is inserted through the screw hole 16 of the component 12 and screwed into the threaded hole 18 of the component 10. The coil spring 20 surrounding the threaded shaft of the screw 14 serves as a spacer between the parts 10 and 12. The coil spring 20 is formed by winding a spring wire having a rectangular cross section, for example.

[0029] The screw hole 16 of the second part 12 is formed at the bottom of the pot-shaped recess 22 which is embossed in the sheet metal of the part 12. At the periphery of the screw hole 16, the bottom of the recess 22 forms a threaded structure 24, which is shaped as a spiral flange, which is interrupted at one point and forms a single spiral loop. The recess 22, the screw hole 16, and the thread structure 24 can be stamped and embossed in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com