Automatic buckle structure

An automatic and rotating part technology, applied in the field of vehicles, can solve the problems of increasing labor costs, incompatible with automation and unmanned, and achieve the effect of saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

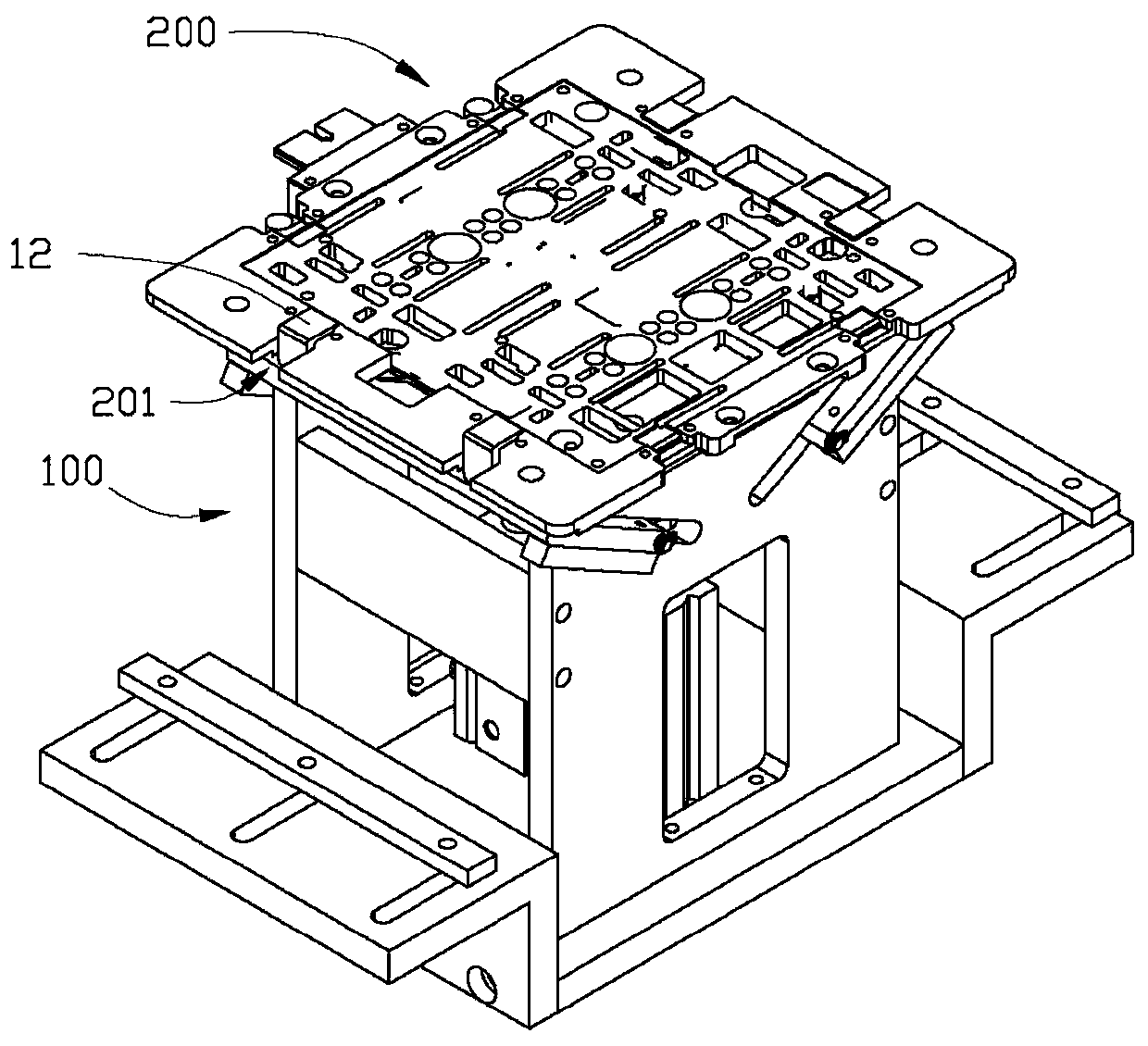

[0029] see figure 1 , providing an automatic fastening structure 100 for automatically fastening a plurality of press buttons 12 on a carrier 200 .

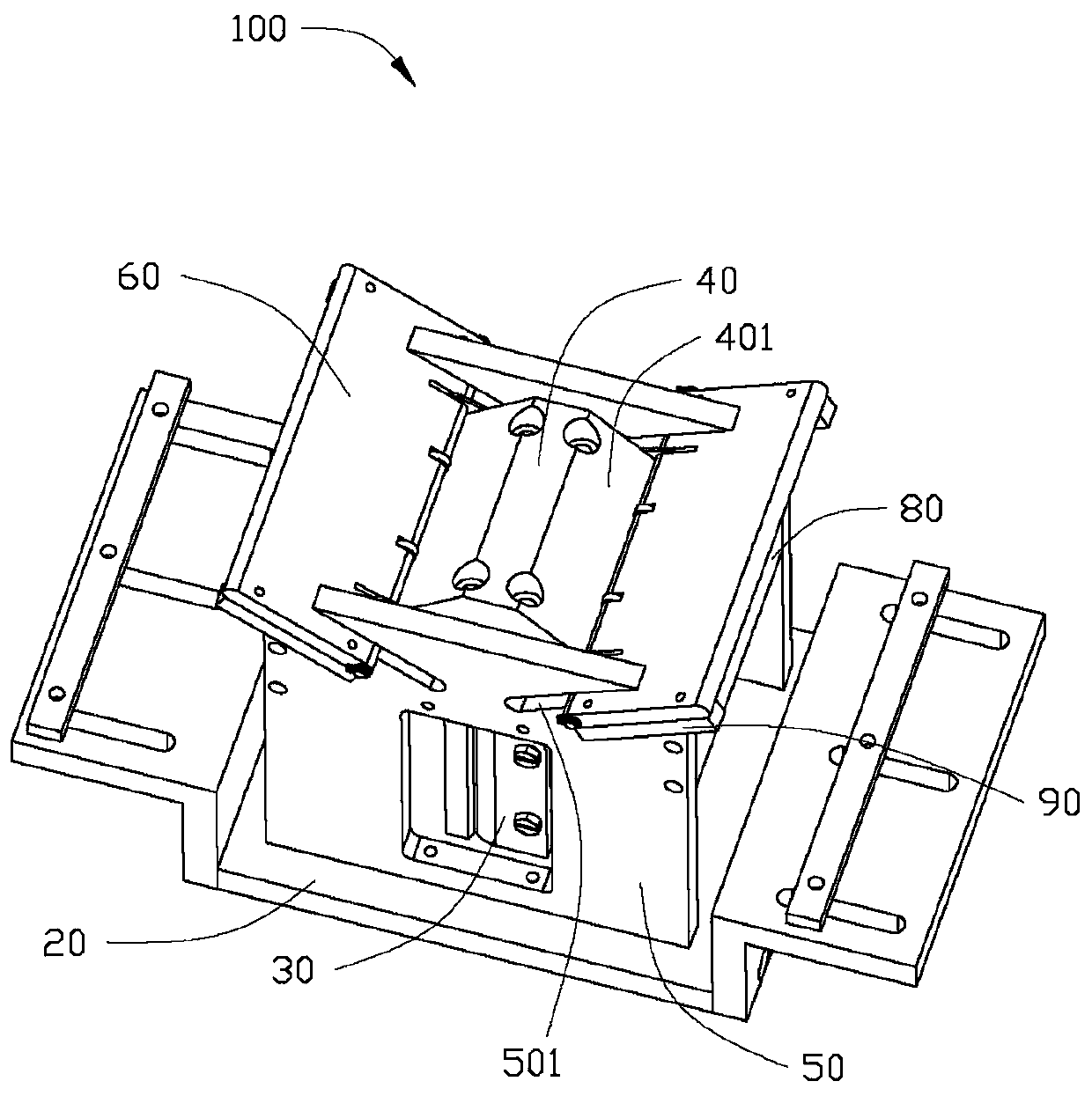

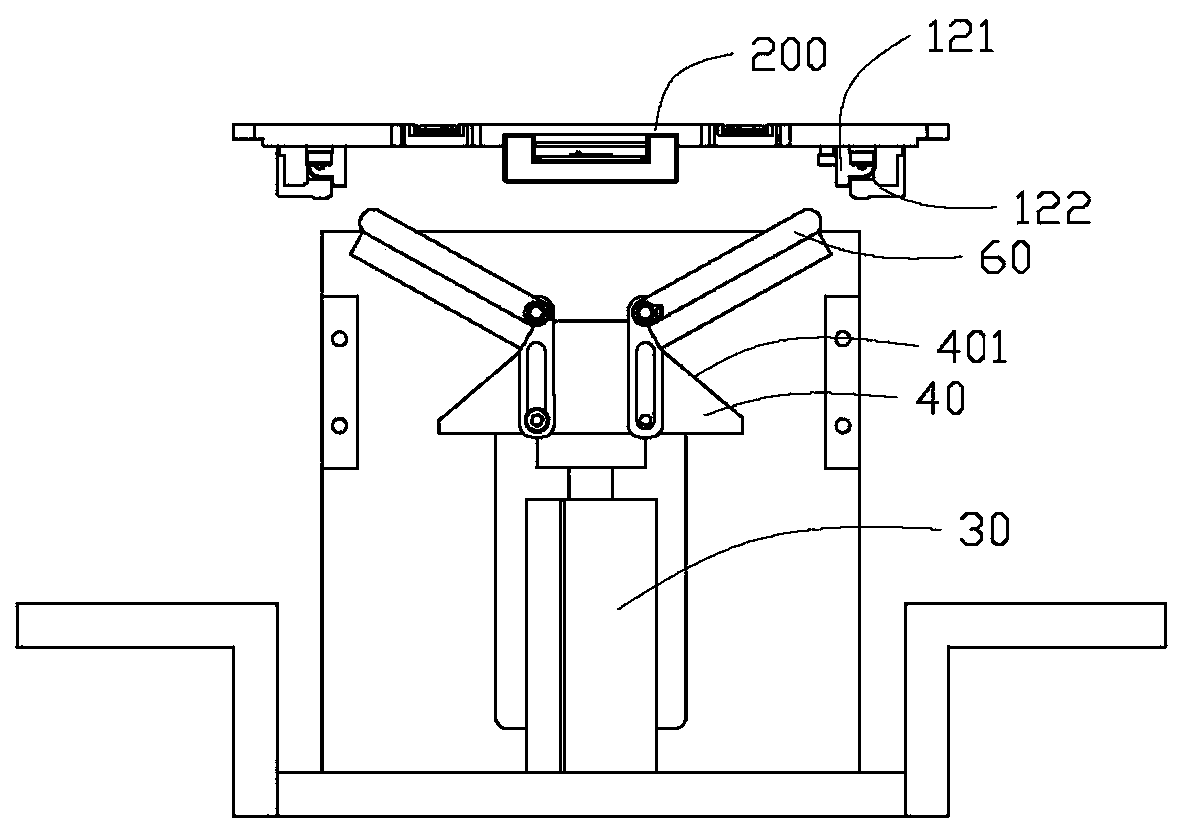

[0030] see figure 2 , the automatic fastening structure 100 includes a base 20 , a cylinder 30 fixed on the base 20 , a push block 40 fixed on the cylinder 30 , A pair of support blocks 50. Wherein, the push block 40 includes a pair of splayed wedge surfaces 401 formed on opposite sides of the push block, and a pair of inverted splayed guide slots 501 are formed on the upper end of each support block.

[0031] The automatic fastening structure 100 further includes a pair of sliding blocks 60 respectively disposed on the opposite sides of the push block 40 and abutting against the wedge-shaped surface 401 of the push block 40 . Wherein, opposite ends of each sliding block 60 are snapped into the guiding slots 501 of the pair of supporting blocks 50 respectively, and each sliding block 60 can slide in the corresponding guiding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com