Rail plate steel bar skeleton lifting tool

A technology of steel frame and hoisting tool, which is applied in the directions of load hanging components, transportation and packaging, can solve the problems of disintegration of the frame, insufficient overall rigidity of the steel frame, deformation, etc., to achieve a good flexible connection, improve stability and lifting. Ability, Deformation Prevention Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Specific embodiments of the invention will be described in detail below in conjunction with the accompanying drawings.

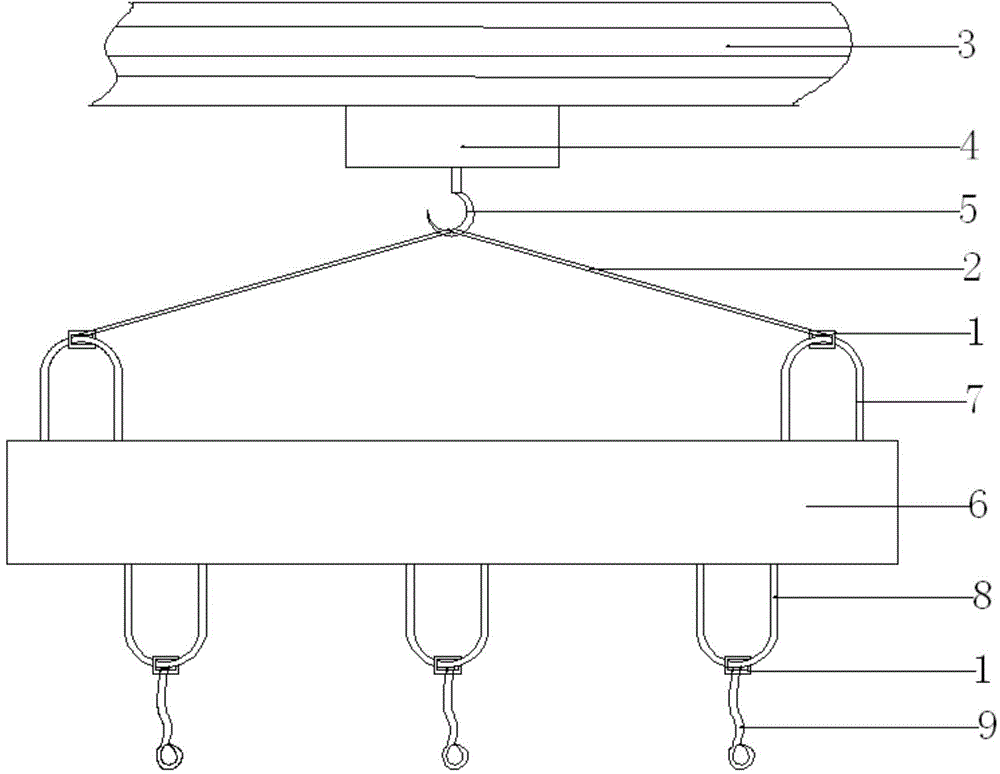

[0013] Such as figure 1 As shown, the best embodiment of the hoisting tool for the steel frame of the track slab includes a truss-type sliding spreader, a walking frame, a safety lock 1 and a sling 2, and the truss-type sliding spreader includes a truss girder 3, a mobile device 4 and a A hook 5, the hook 5 is connected to the truss girder 3 through the moving device 4, and the hook 5 can move along the truss girder 3, and the walking frame is located on the truss type sliding hanger Below, the main body of the walking frame is composed of four supporting beams 6 connected in sequence. The supporting beams 6 in the same walking direction as the hook 5 are provided with a number of upper lifting lugs 7 and lower lifting lugs 8. The upper lifting lugs 7 and the lower lifting lug 8 are arranged on the upper and lower sides of the support beam 6 opposite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com