Rail hoisting device and using method thereof

A technology of rail cranes and rails, which is applied in the direction of transportation and packaging, load hanging components, etc., can solve problems such as uneconomical and unreasonable, has not yet found rail hoisting, labor and time-consuming problems, and achieves the effect of improving transportation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

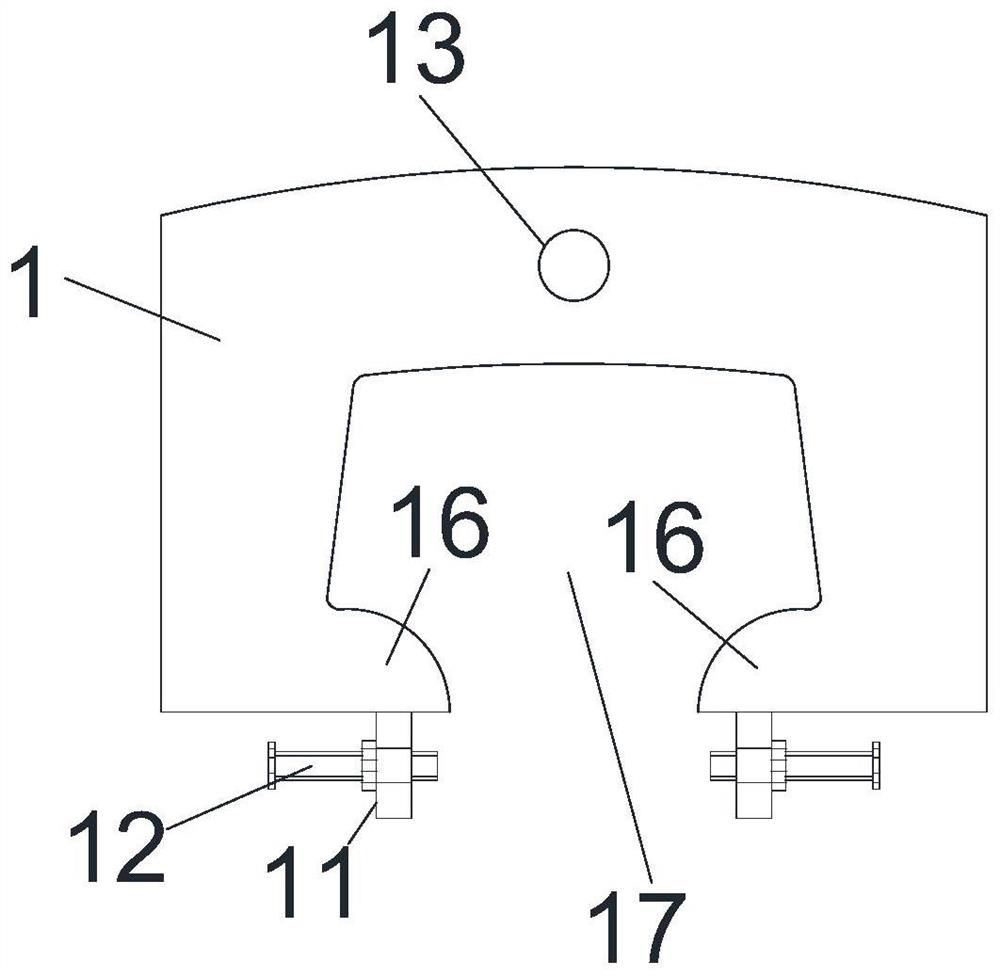

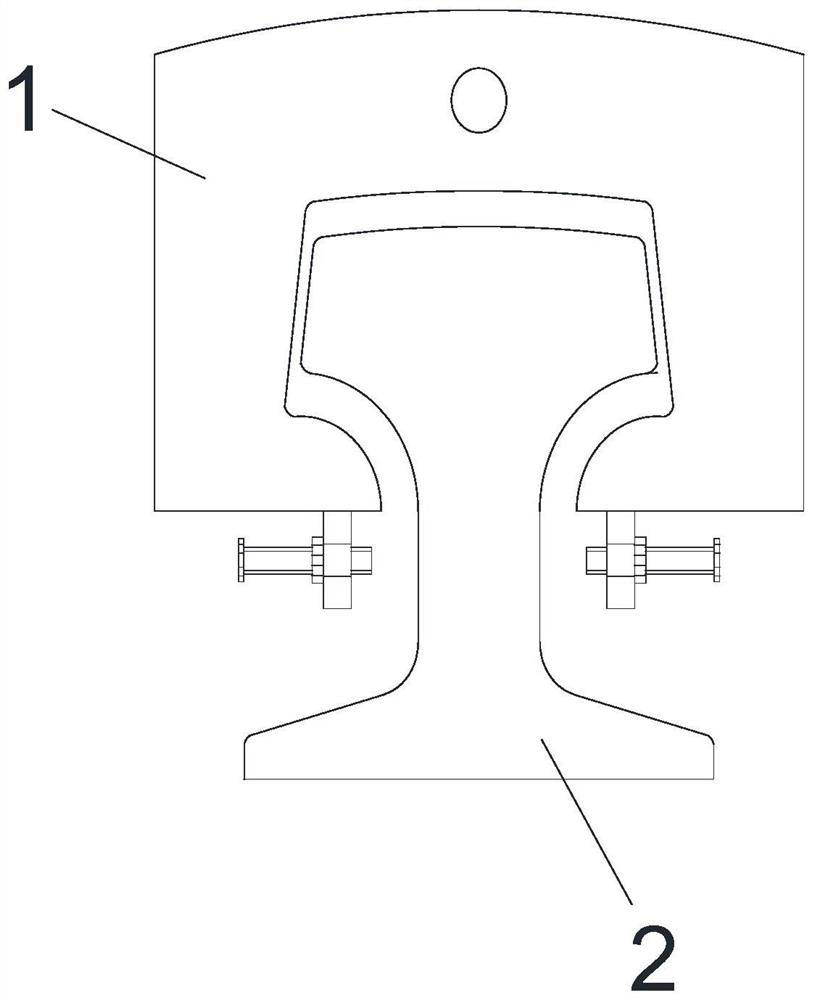

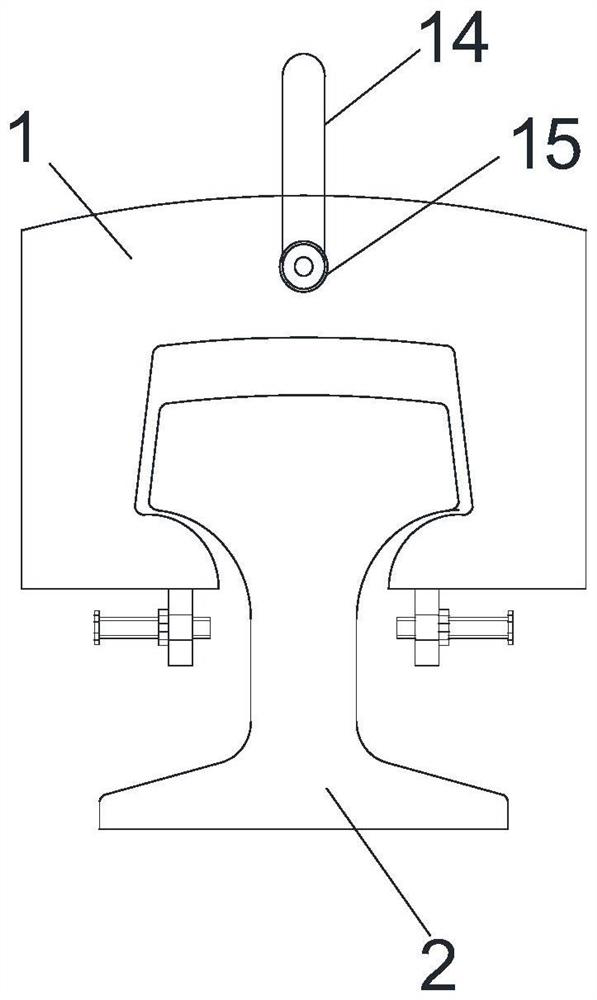

[0017] Such as Figure 1 to Figure 5 The rail hoisting device shown includes a hook body 1, and the hook body 1 includes a pair of hook tips 16, wherein, the hook body 1 forms a rail head lifting slot structure 17 through the hook tips 16, so that A rail waist fastening structure is provided at each hook tip 16 described above.

[0018] The invention solves the problem that the rail hoisting and installation do not require frequent hanging and loosening of steel wire ropes. In actual use, the hoisting and installation of the track can be carried out quickly, which improves the installation efficiency, saves the installation period, greatly improves the construction efficiency, and makes the construction safer, more reliable and faster. In addition, the hook body 1 is preferably made of Q235 conventional steel, which can be made from local materials, can be reused, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com