Tooling plate for arrangement and plastic suction molding of rhinestones

A technology of blister molding and tooling, which is applied in the field of rhinestone processing, and can solve problems such as unstable movements, low efficiency of blister molding, and complex process structures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

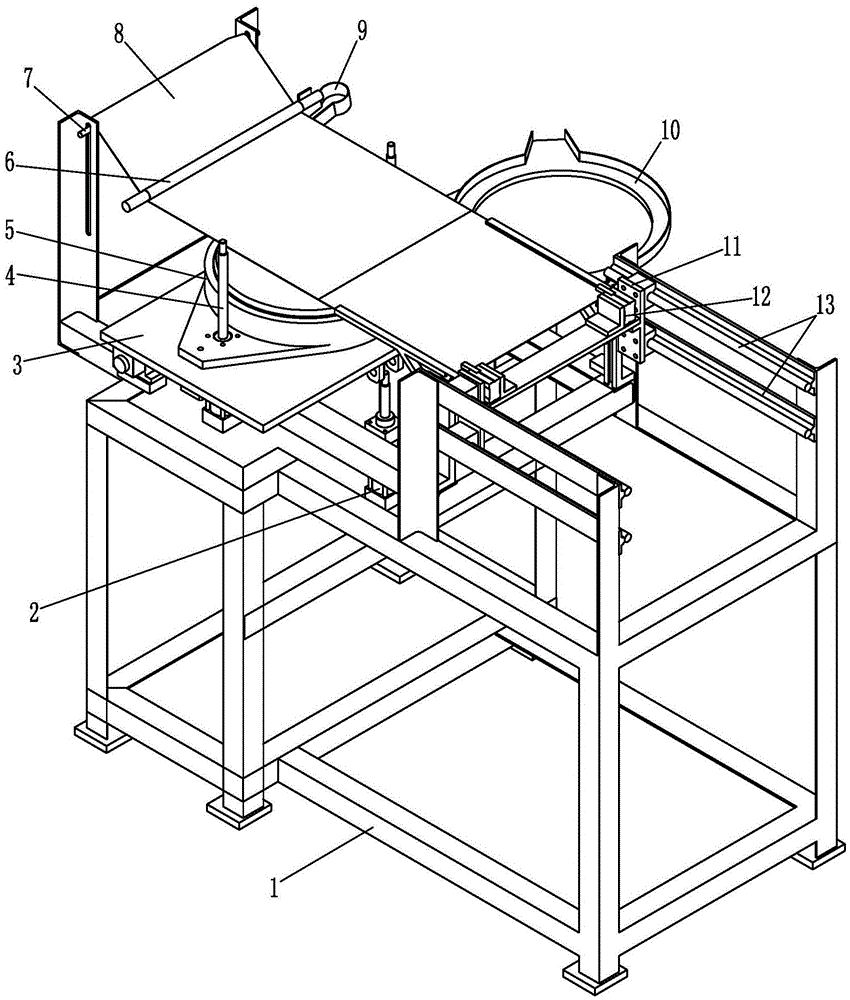

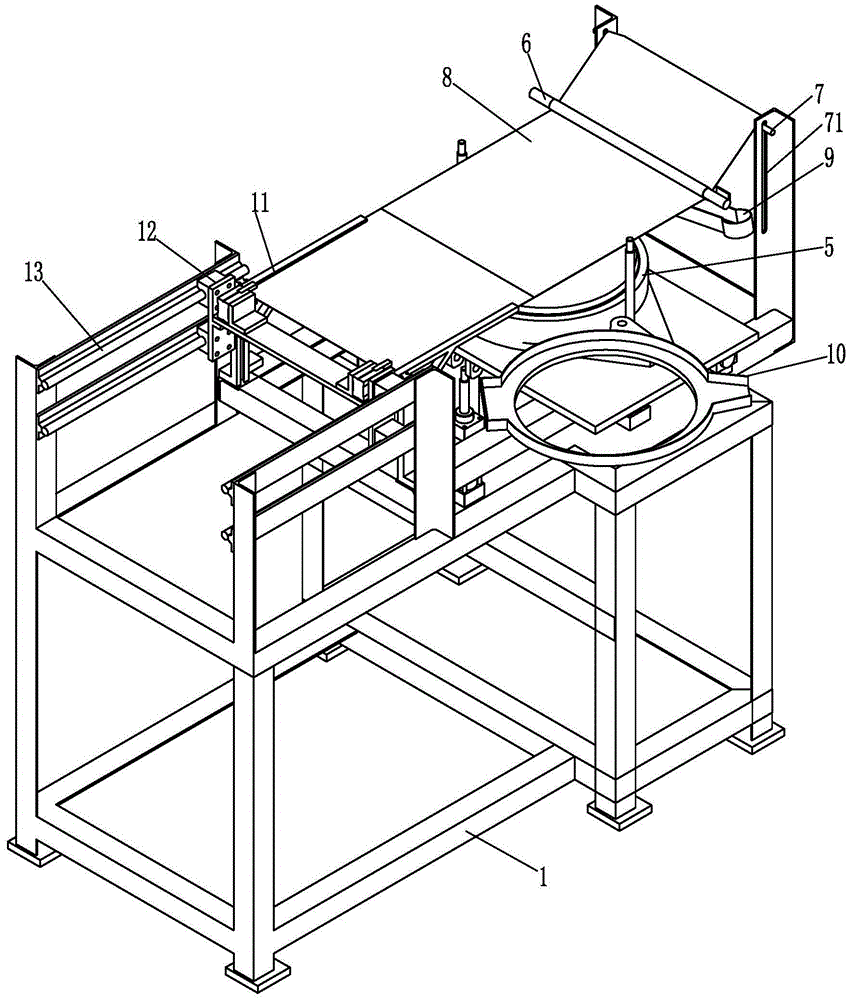

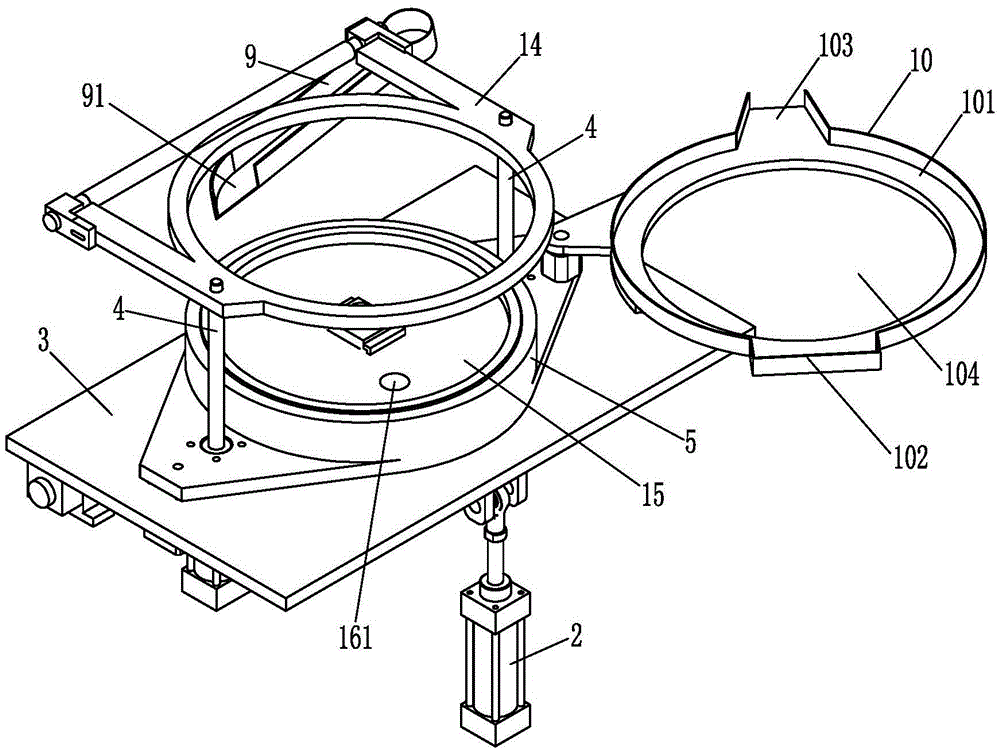

[0080] Such as Figure 5-20 As shown, the present invention provides a specific embodiment of a tooling plate for rhinestone arrangement and blister molding. The tooling plate 16 is provided with a plurality of embedding holes 161 for embedding the rhinestones 21. The air hole 163 communicates with the vent hole and the vacuum pump; the plate surface of the tooling plate 16 includes a first tooling plate surface and a second tooling plate surface, the first tooling plate surface is higher than the second tooling plate surface, and multiple second tooling plate surfaces The first tooling plate surface is formed therebetween, and the embedding hole extends downward from the first tooling plate surface to below the second tooling plate surface. The second tooling plate surface is arranged around the embedding hole and connected to the embedding hole. When the rhinestone 21 is embedded in the embedding hole, the first tooling plate face and the second tooling plate face are respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com