Stabilizing operation control method of main-line turnout stabilizing carriage in turnout zone

A technology of main line turnout and control method, which is applied in the direction of road, track, ballast layer, etc., and can solve the problem of inability to realize the switching of clamping action, rail support action clamp pressure and support rail pressure, and the inability to realize stable operation in the turnout area , the control method is not accurate enough, etc., to achieve the effect of solving stable maintenance requirements, simple design and implementation, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 11

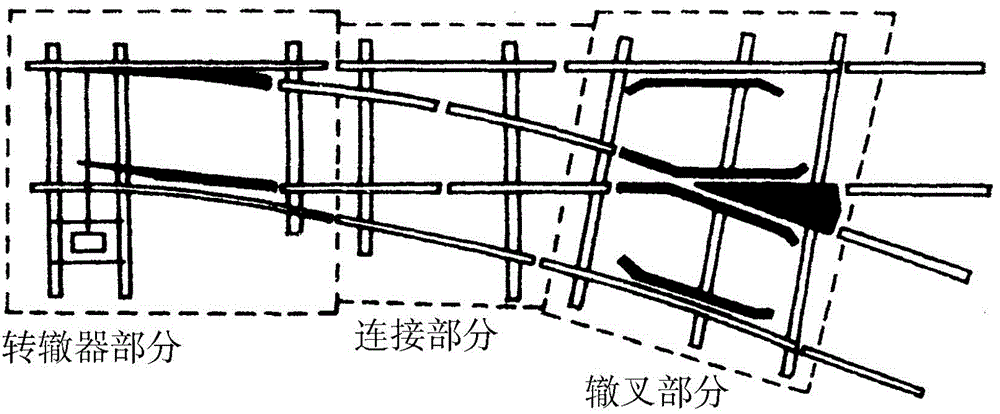

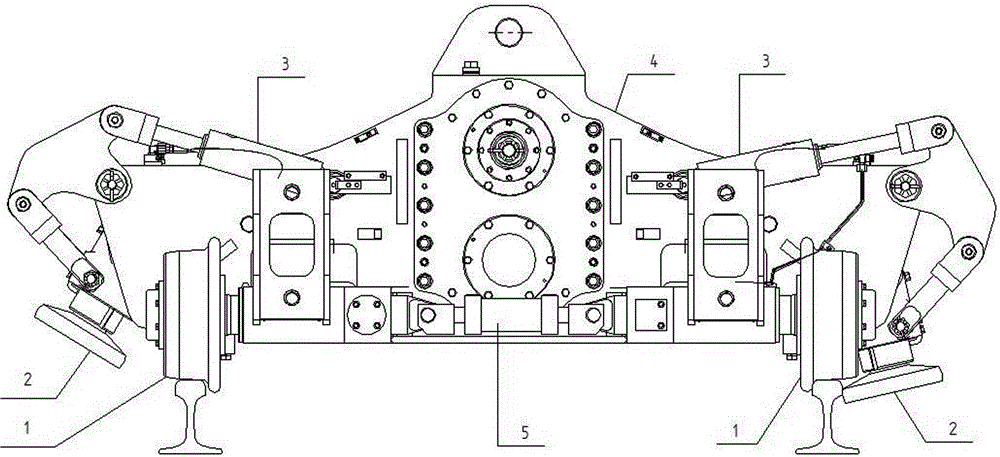

[0031] Example 1.1 : A control method for the stability operation of the main line turnout stabilization vehicle in the turnout area. Taking the stability operation of the standard gauge track as an example, the operation of the main line turnout area is divided into five stages, namely stage Ⅰ: main line operation before the turnout Stage, stage Ⅱ: unilateral clamping stage of the point switch part, stage Ⅲ: normal main line operation stage of the connecting part, stage Ⅳ: unilateral rail clamping stage of the frog part, stage Ⅴ: main line after exiting the turnout job stage. Set the direction where the rail is close to the forward head of the work vehicle as the front, and the direction where the rail is away from the forward head of the work vehicle is the rear. square.

[0032] In this embodiment, the control method for the stability operation of the main line turnout stabilization vehicle in the turnout area includes the preparation stage, the 1st step, the 2nd step, t...

Embodiment 12

[0041] Example 1.2 : a method for controlling the stability of the main line turnout stabilization vehicle in the turnout area, the same as embodiment 1.1, the difference is that after the steps of embodiment 1.1 are performed, when the next group of turnouts is encountered, the switch will Repeat steps 2, 3, and 4 in sequence.

Embodiment 13

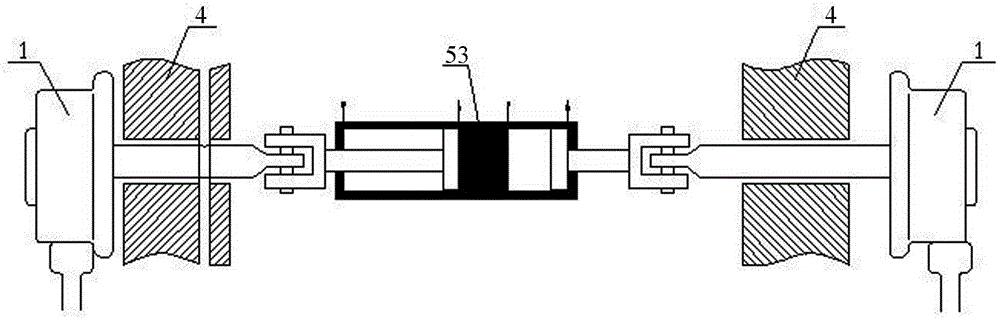

[0042] Example 1.3 : a method for controlling the stable operation of the main line turnout stabilization vehicle in the turnout area, the same as embodiment 1.1, the difference is that the horizontal support rail oil cylinder is a combined oil cylinder with two piston rods, and the combined oil cylinder has a stroke of 15mm Piston rod II at one end and piston rod I at one end with a stroke of 20 mm are respectively embedded in the two ends of the cylinder barrel of the horizontal rail cylinder, and the adjustment of different wheelbase widths is realized by controlling the oil circuits of piston rod I and piston rod II respectively. When the connecting part of the main line section and the turnout section performs stable operation, the clamping pressure of the clamping cylinder is 10Mpa. When the switch part and the frog part of the switch section perform stable operation, the clamping side of the clamping cylinder The corresponding clamping pressure is 15MPa, and the clampi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com