Current sensor fault reconstruction method

A technology for current sensors and sensor failures, which is applied in the control of electromechanical brakes, electromechanical transmissions, electrical components, etc., and can solve the problems that current sensor failures cannot be reconfigured

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

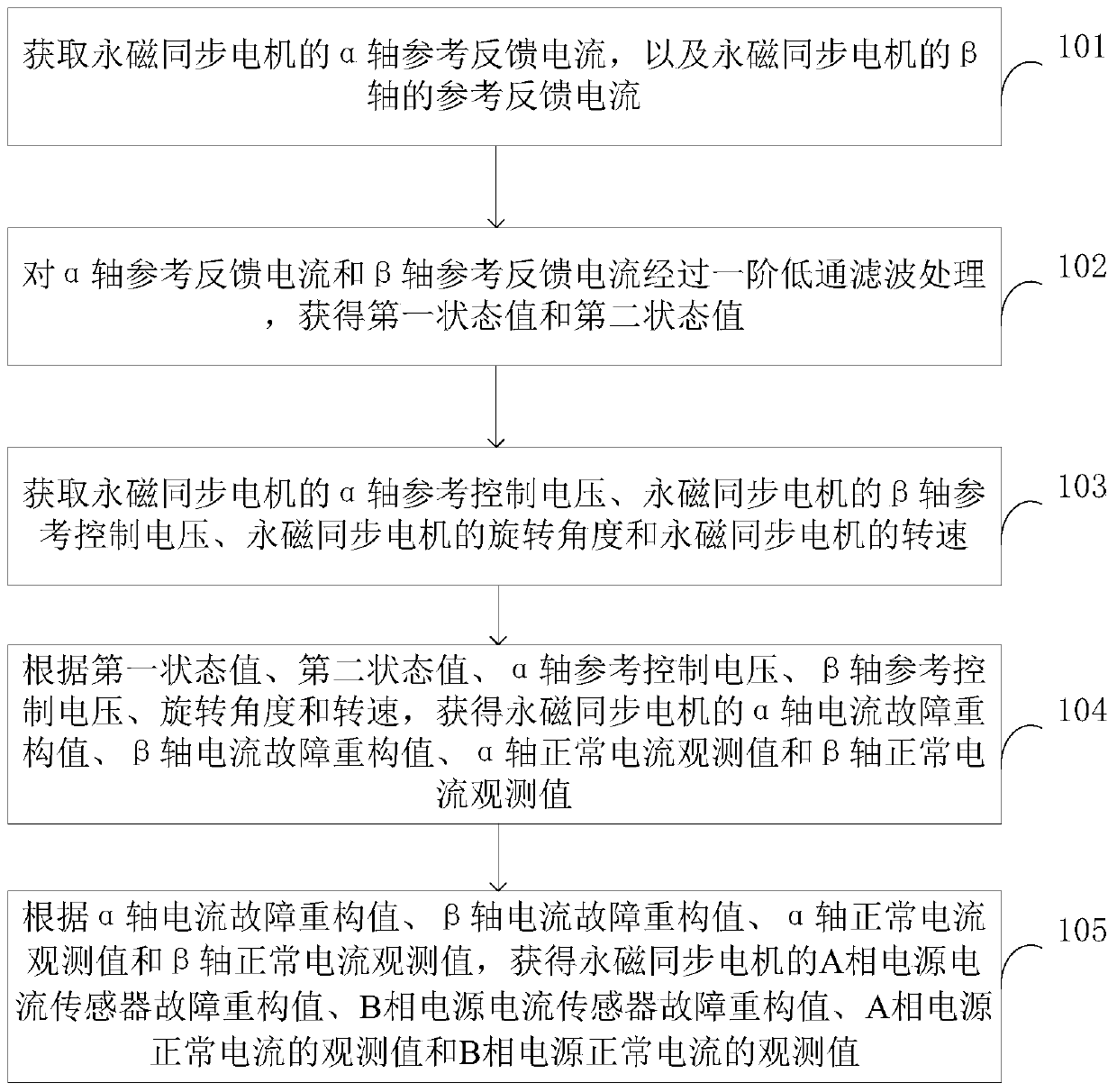

[0059] The executive subject of the current sensor fault reconstruction method in this embodiment is the current sensor fault reconstruction device, figure 1 It is a schematic flowchart of a current sensor fault reconfiguration method according to Embodiment 1 of the present invention. As shown in FIG. 1 , this embodiment provides a current sensor fault reconfiguration method, the method is based on a permanent magnet synchronous motor control system, include:

[0060] Step 101, obtain the α-axis reference feedback current i of the permanent magnet synchronous motor α , and the reference feedback current i of the β-axis of the permanent magnet synchronous motor β .

[0061] Step 102, refer to the feedback current i for the α-axis α and the β-axis refer to the feedback current i β After a first-order low-pass filtering process, the first state value z is obtained 1 and the second state value z 2 .

[0062] Step 103, obtain the α-axis reference control voltage u of the pe...

Embodiment 2

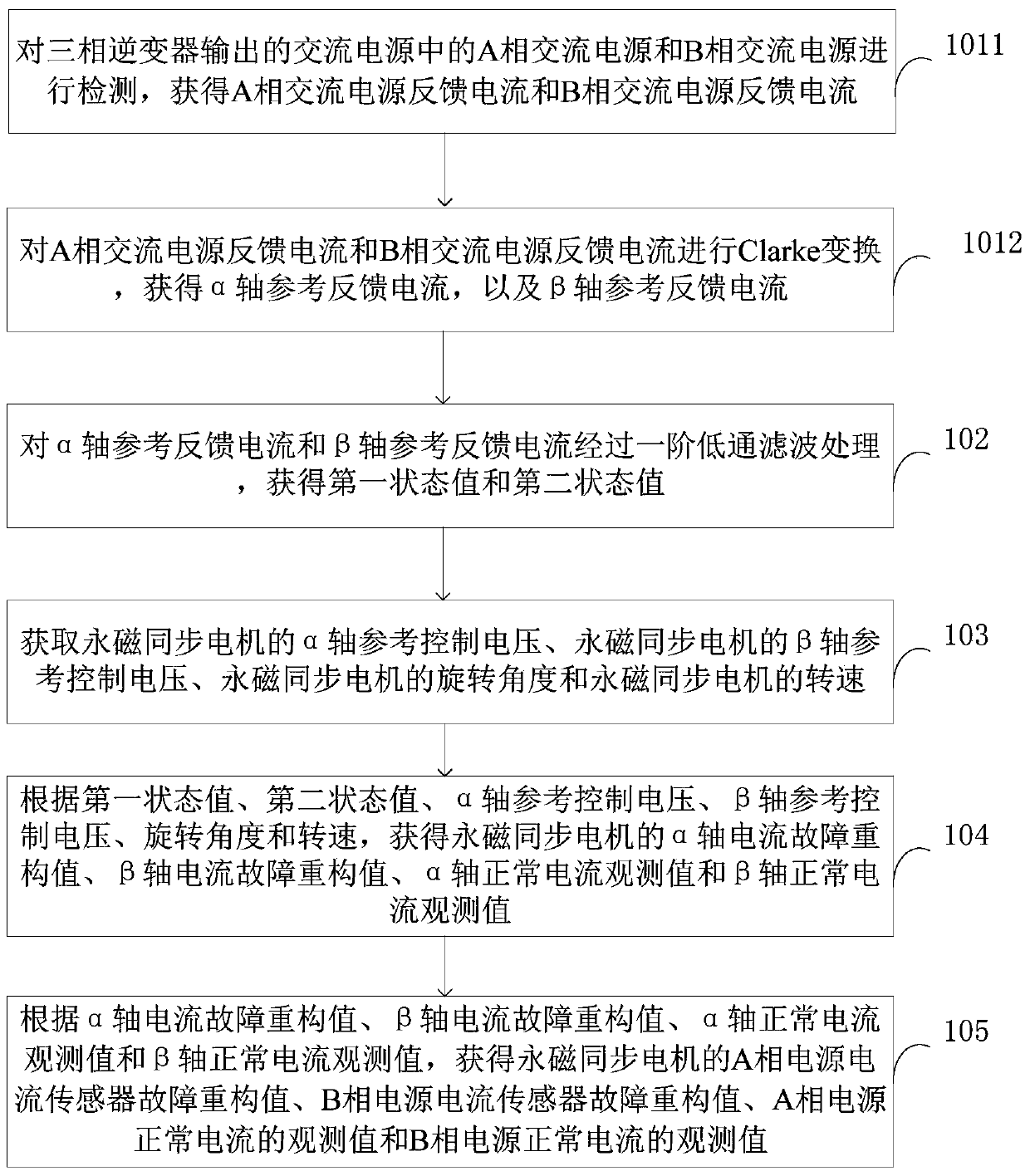

[0069] This embodiment is a supplementary description based on the above embodiments.

[0070] figure 2 It is a schematic flowchart of a current sensor fault reconfiguration method according to Embodiment 2 of the present invention, as shown in FIG. 2 , this embodiment provides a current sensor fault reconfiguration method, the method is based on a permanent magnet synchronous motor control system, include:

[0071] Step 101, obtain the α-axis reference feedback current i of the permanent magnet synchronous motor α , and the reference feedback current i of the β-axis of the permanent magnet synchronous motor β .

[0072] Further, step 101 specifically includes:

[0073] Step 1011: Perform signal detection on the A-phase AC power supply and the B-phase AC power supply in the AC power supply output by the three-phase inverter, and obtain the feedback current i of the A-phase AC power supply A and B-phase AC power feedback current i B .

[0074] Specifically, signal detec...

Embodiment 3

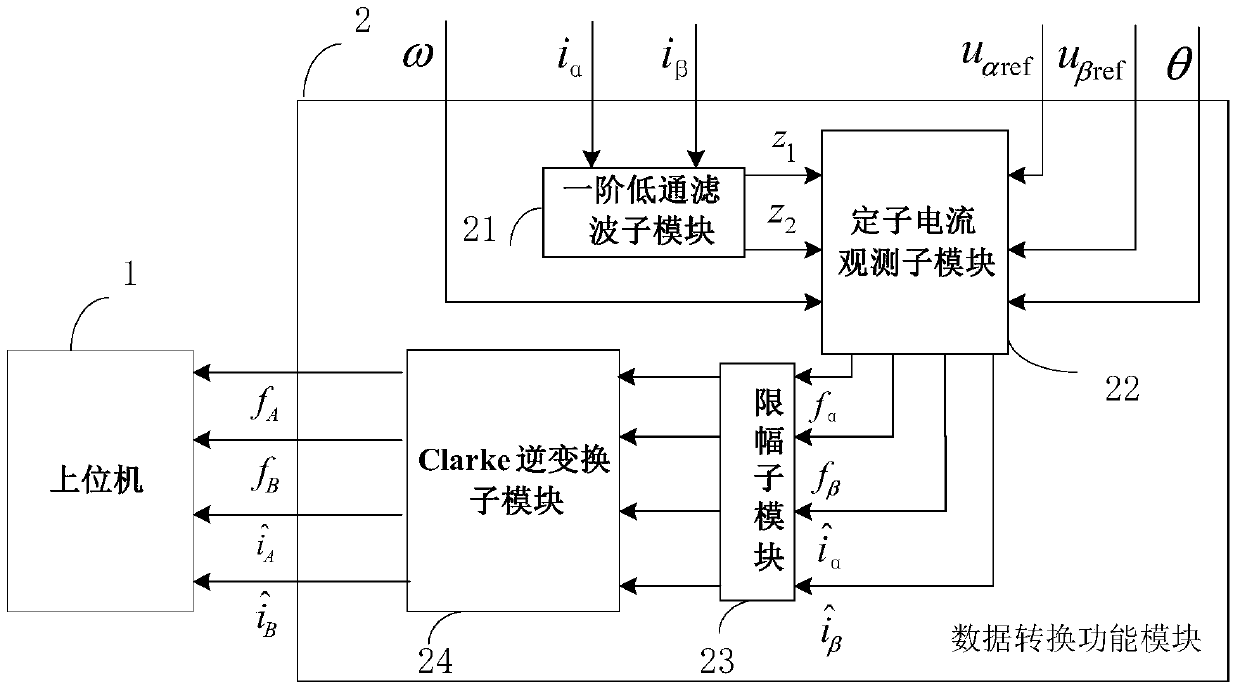

[0102] The current sensor fault reconfiguration device of this embodiment is used to implement the above current sensor fault reconfiguration method. image 3 It is a schematic structural diagram of a current sensor fault reconfiguration device according to Embodiment 3 of the present invention, as shown in FIG. 3 , this embodiment provides a current sensor fault reconfiguration device, the device is based on a permanent magnet synchronous motor control system, Including: data conversion function module 2, data conversion function module 2 includes first-order low-pass filter sub-module 21, stator current observation sub-module 22, clipping sub-module 23 and Clarke inverse transformation sub-module 24; stator current observation sub-module 22 respectively It is connected with the first-order low-pass filter sub-module 21 and the clipping sub-module 23 , and the clipping sub-module 23 is also connected with the Clarke inverse transform sub-module 24 .

[0103] Among them, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com