Fault locating apparatus of non-contact electromagnetic induction of AT power traction system and fault locating method thereof

A technology of electromagnetic induction and fault location, applied in fault location, information technology support system, etc., can solve difficult to achieve, frequency-dependent effect of traveling wave signal parameters, difficult to extract and process traveling wave signal, and inaccurate time of different monitoring points. Synchronization and other problems to achieve the effect of improving efficiency, troubleshooting and restoring power supply, saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

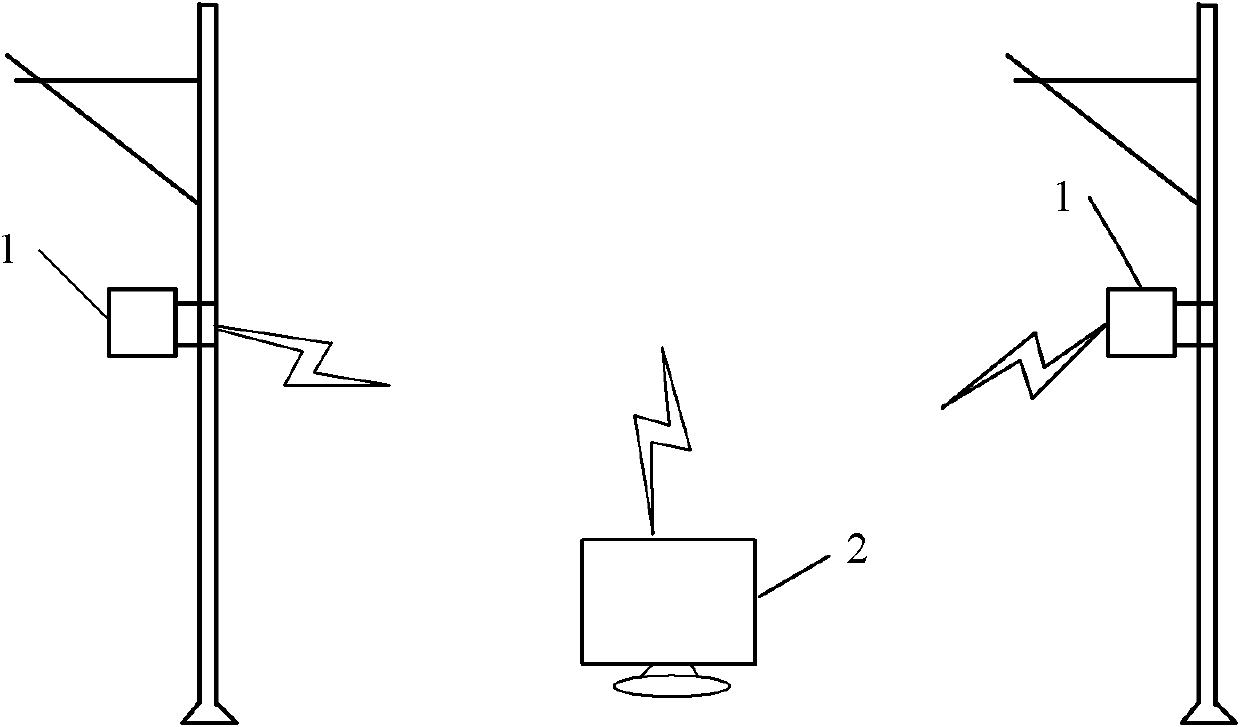

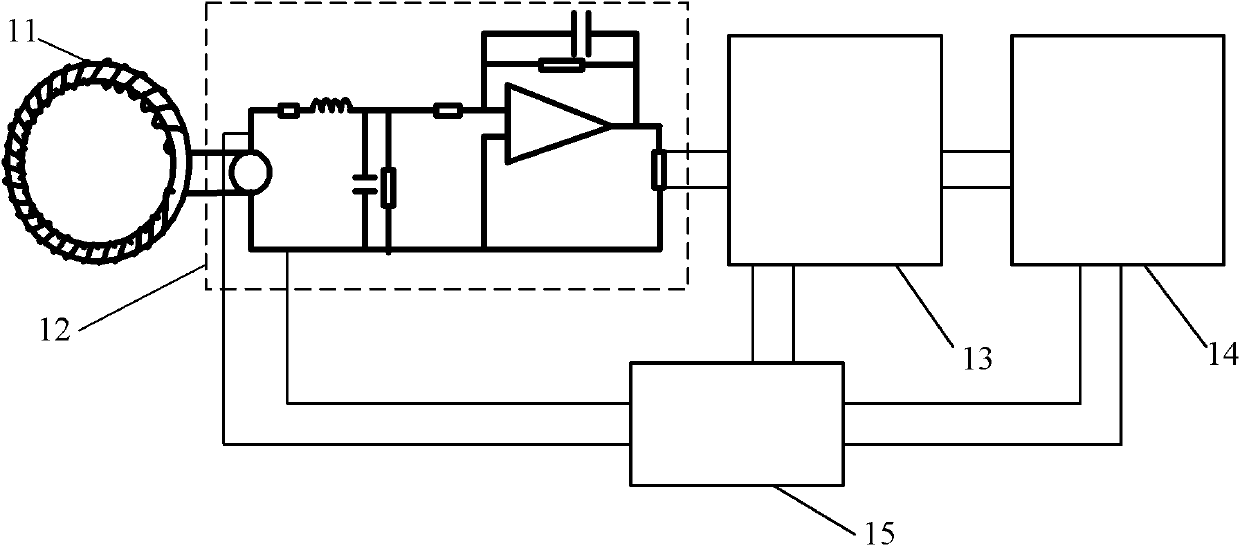

[0023] figure 1 , figure 2 As shown, a specific embodiment of the present invention is a non-contact electromagnetic induction fault location device for an AT power supply traction network, which consists of:

[0024] An electromagnetic induction fault locator 1 is installed on the traction network pole tower of the AT power supply mode, and a remote terminal computer 2 with a GSM signal receiving module is installed at the traction substation; the electromagnetic induction fault locator is composed of an electromagnetic induction coil 11, a voltage amplification circuit 12. The single-chip microcomputer 13 and the GSM signal transmitting module 14 are sequentially connected to form, and the voltage amplifying circuit 12 , the single-chip microcomputer 13 and the GSM signal transmitting module 14 share a power supply 15 .

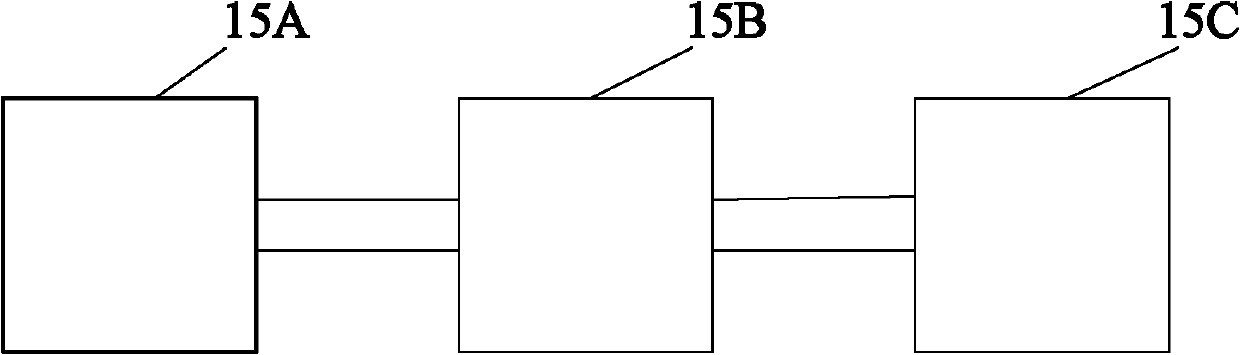

[0025] image 3 It is shown that the power source 15 of this example is a solar power source composed of a solar panel 15A, a solar charge controller 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com