Patents

Literature

41results about How to "Save running memory" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

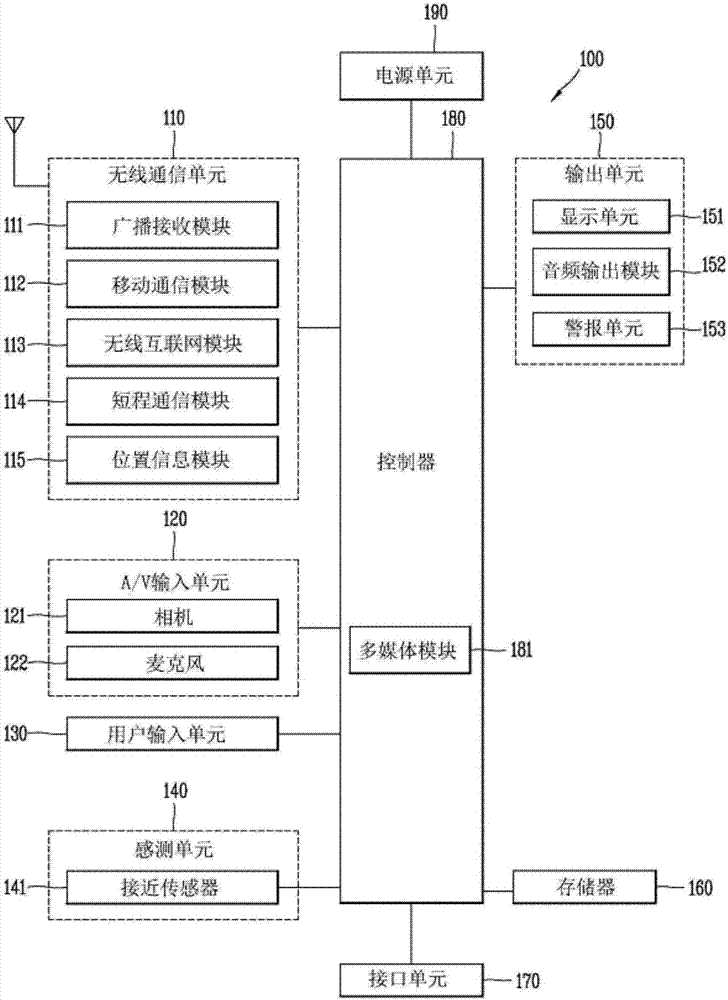

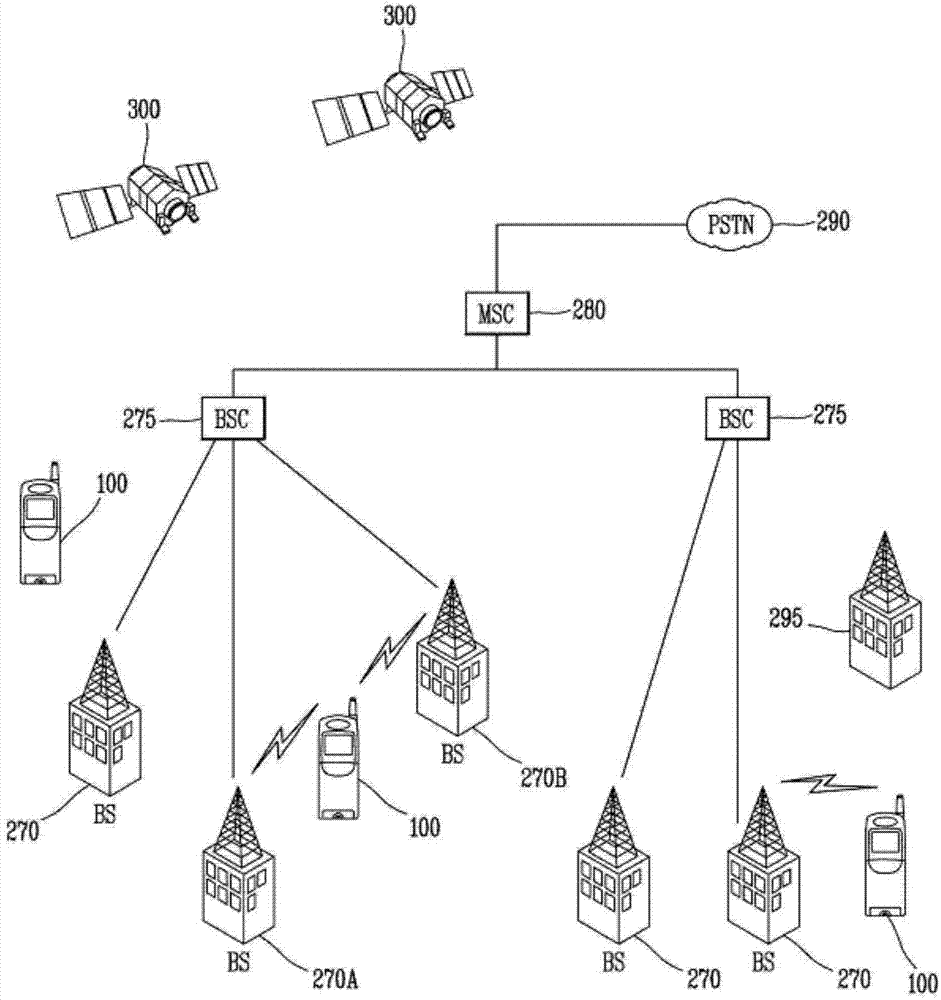

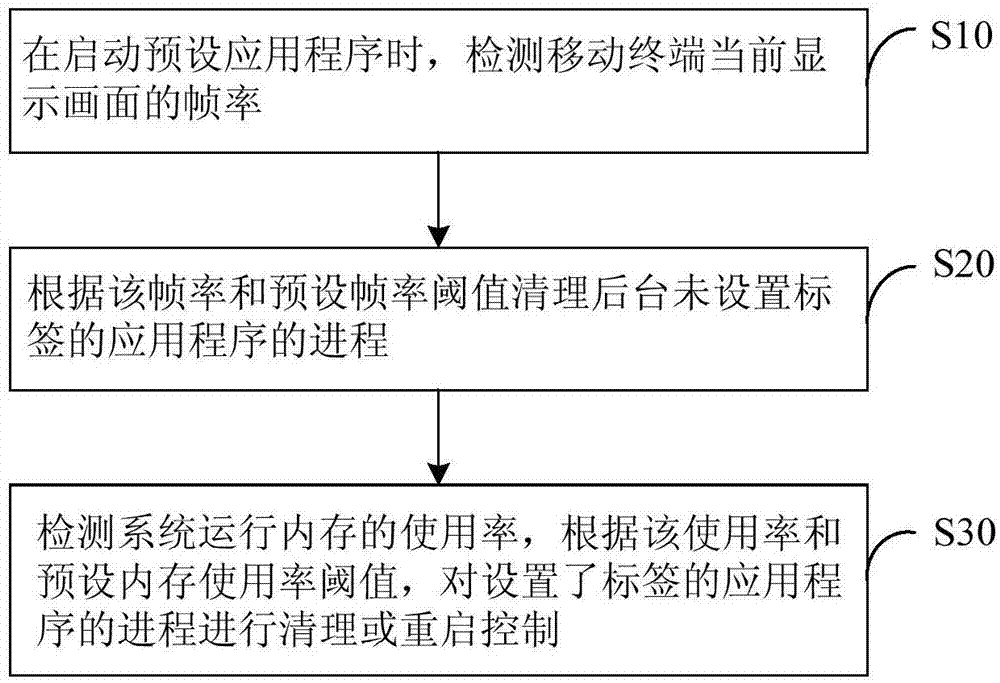

Method for intelligently optimizing internal storage of mobile terminal and mobile terminal

InactiveCN104714874AImprove experienceSave running memoryHardware monitoringSoftware engineeringComputer terminal

The invention discloses a method for intelligently optimizing internal storage of a mobile terminal and the mobile terminal, and belongs to the field of mobile terminals. The method for intelligently optimizing the internal storage of the mobile terminal comprises the steps that when a preset application program is started, the frame rate of a frame currently displayed by the mobile terminal is detected, progresses of application programs without tags set in the background are cleared away according to the frame rate and a preset frame rate threshold value to save the running internal storage of the system, the use rate of the internal storage of the system is detected, progresses of application programs with set tags are cleared away or controlled to be restarted according to the use rate and a preset internal storage use rate threshold value, the started preset application programs have the enough running internal storage, and under the conditions of not changing hardware, the running speed of the system is improved, and user experience is improved.

Owner:NUBIA TECHNOLOGY CO LTD

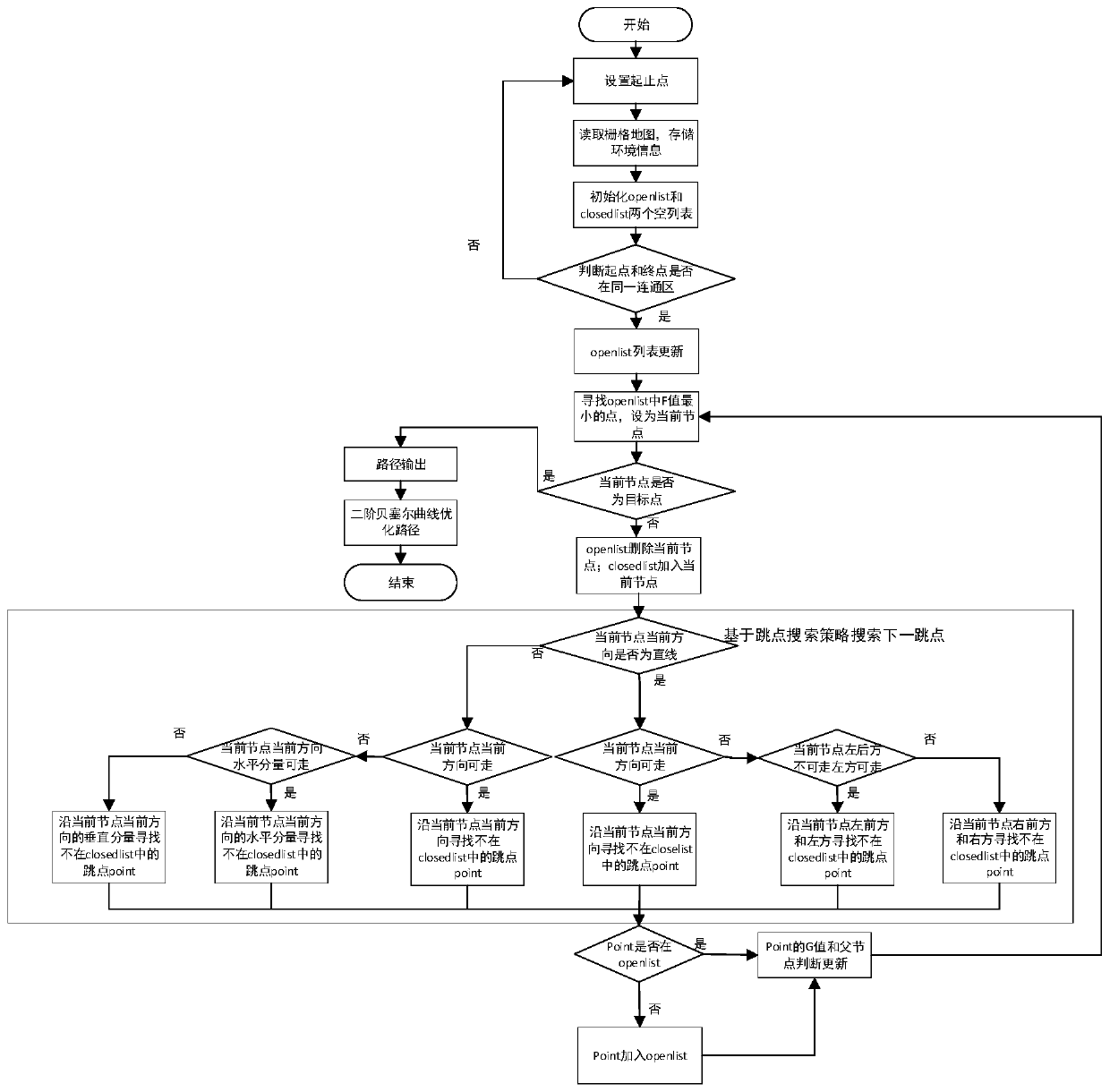

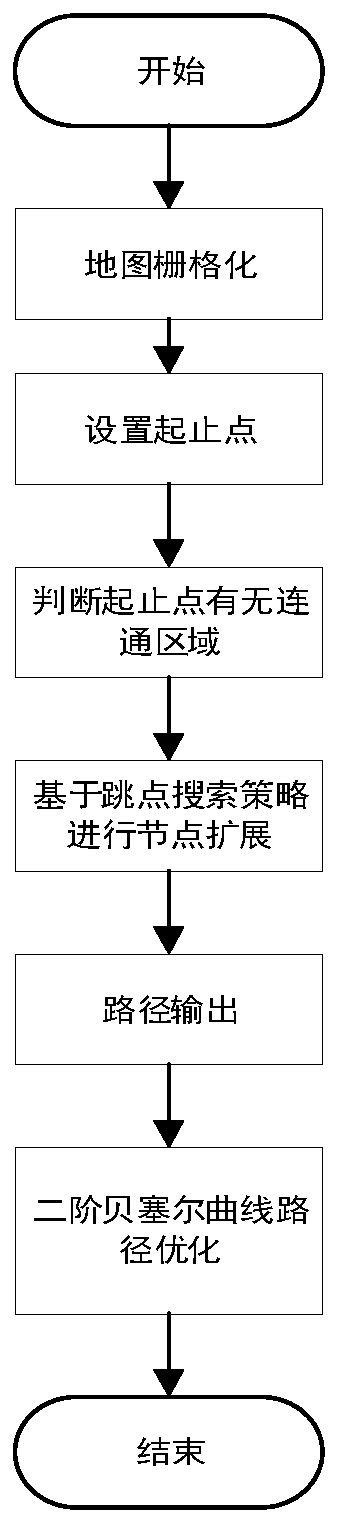

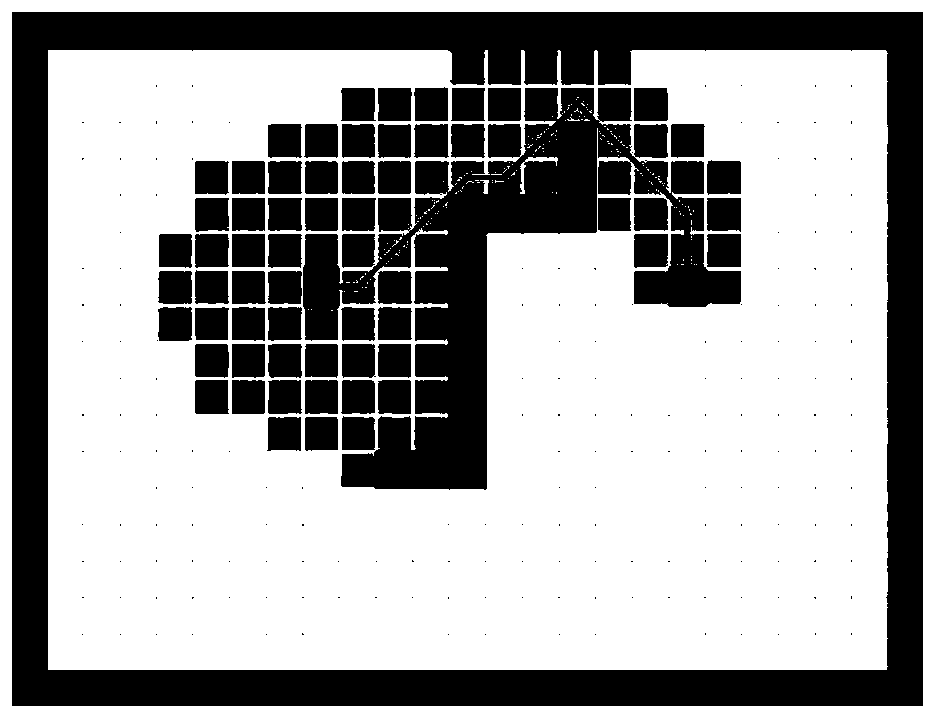

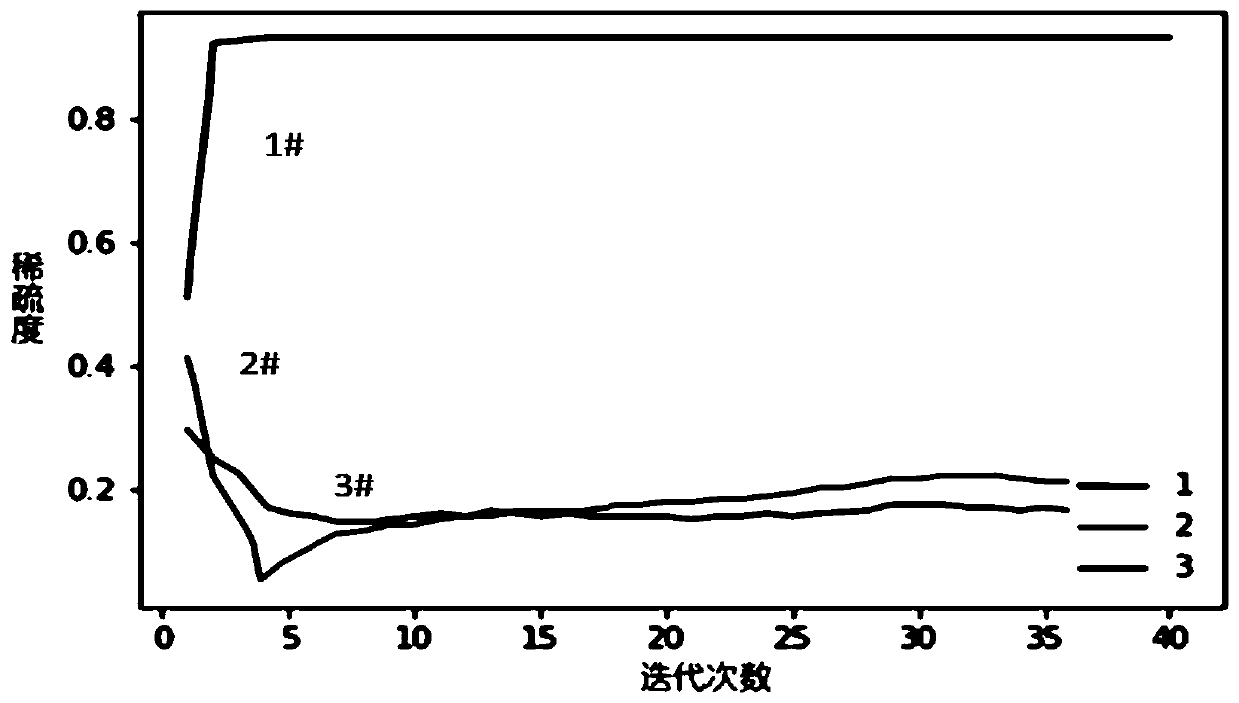

Unmanned ship track planning method based on deep optimization

InactiveCN110006429AOptimize the speed of seekingReduce in quantityNavigational calculation instrumentsEngineeringControl theory

The invention belongs to the technical field of unmanned ship navigation control, and specifically relates to anunmanned ship track planning method based on deep optimization. The unmanned ship trackplanning method based on deep optimization comprises the following steps that rasterized map information is read, starting and ending points are set, the obtained starting point and reachable neighbornodes in the eight directions of the starting pointare added to theopenlist; the point with the smallest F value in the openlistis searched for and set as the current node; whether the current node is the ending point or not is determined; if yes, then path searching is over; if not, then the current node is utilized to search for a next jump-point based on a jump-point search strategy; whether the jump-point is in the openlistor not is determined, and the point with the smallest F value is continuously searched for; and an optimal path is outputted. According to the unmanned ship track planning method based on deep optimization,the execution efficiency of grid method track planning algorithm is greatly improved based on the jump-point search optimization preprocessing algorithm,an path turning point is optimized, and finally a smooth navigation track is outputted.

Owner:智慧航海(青岛)科技有限公司

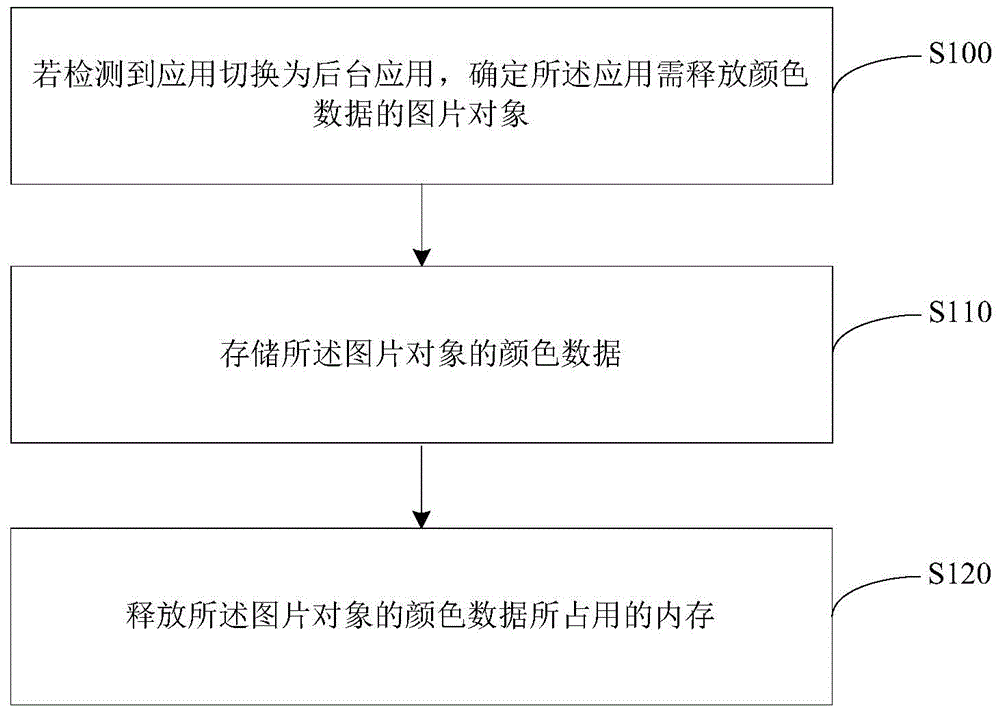

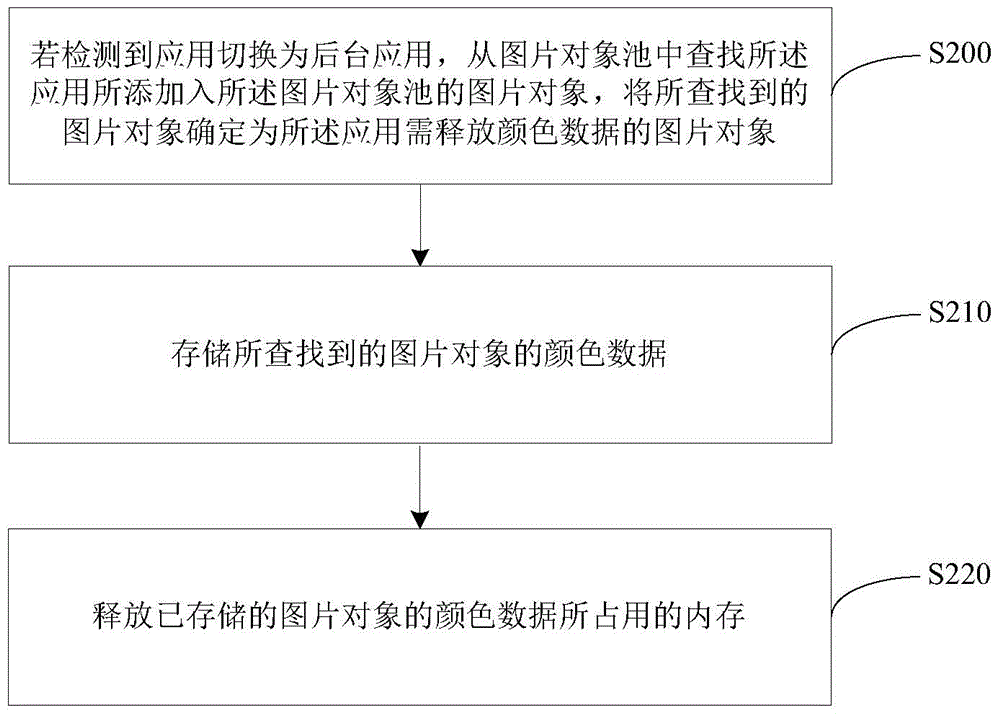

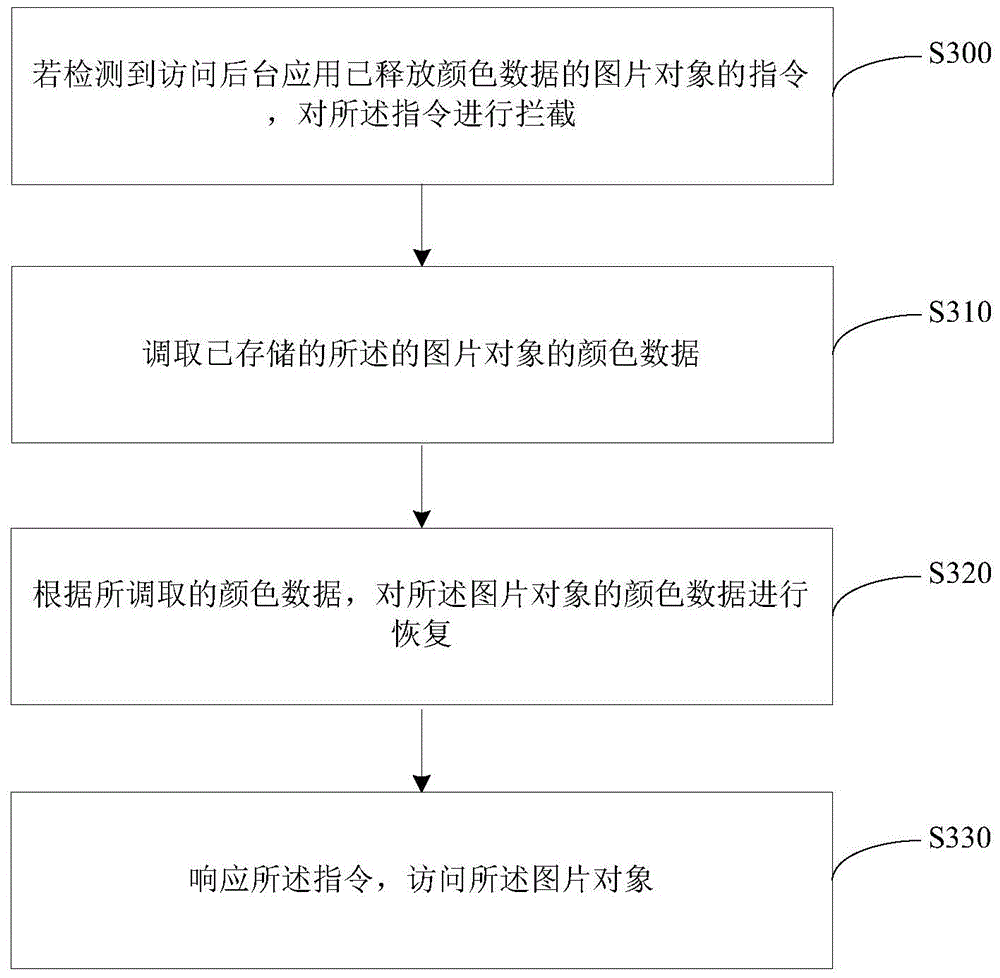

Memory optimization method and device

InactiveCN104461745AOptimize running memorySave running memoryResource allocationTerminal equipmentOperating system

An embodiment of the invention provides a memory optimization method and device. The method comprises the steps of determining an image object with color data to be released by an application if it is switched to a background application; storing the color data of the image object; releasing the memory occupied by the color data of the image object. By means of the memory optimization method and device, the operation memory of a terminal device can be optimized at a lower hardware cost.

Owner:THUNDERSOFT

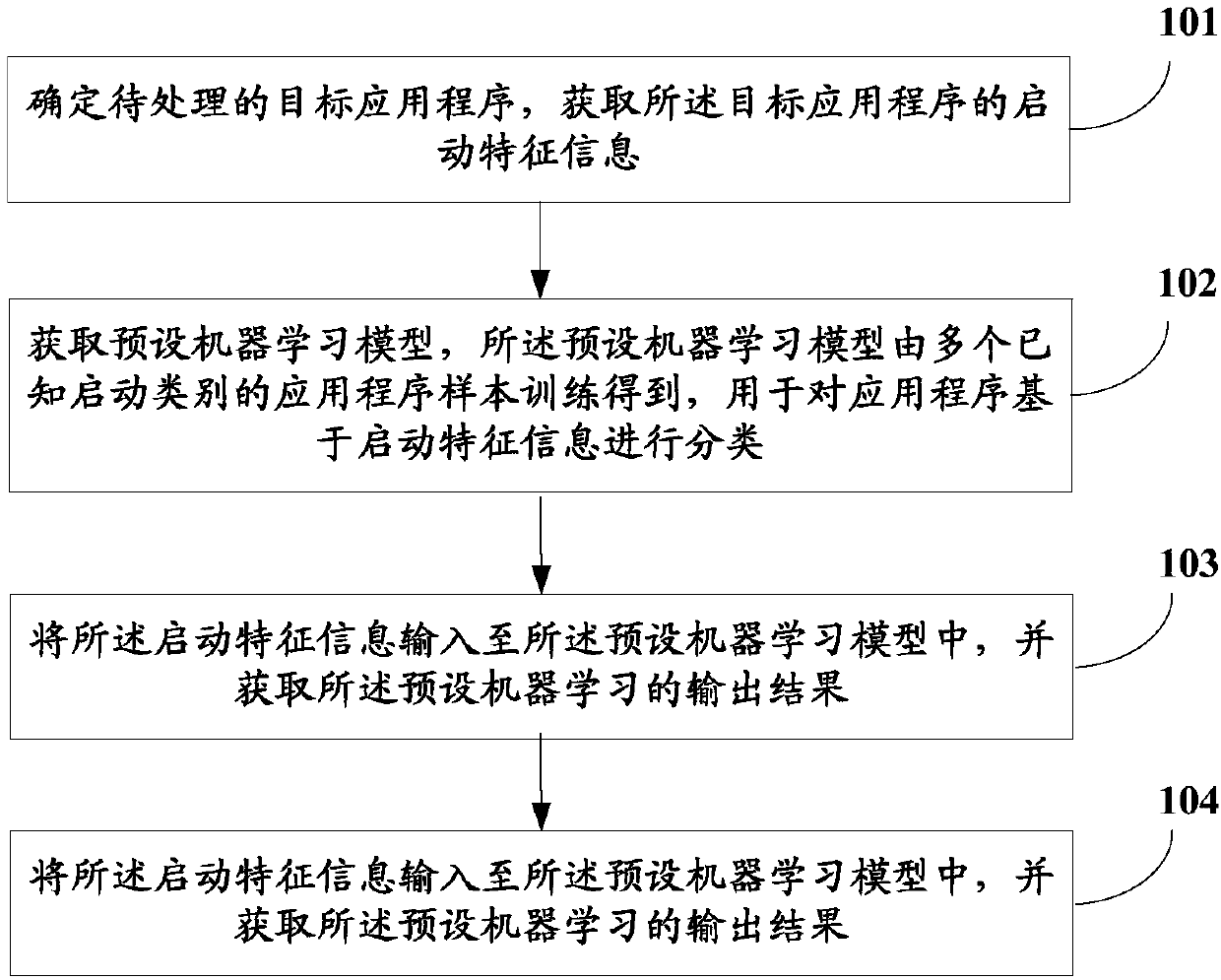

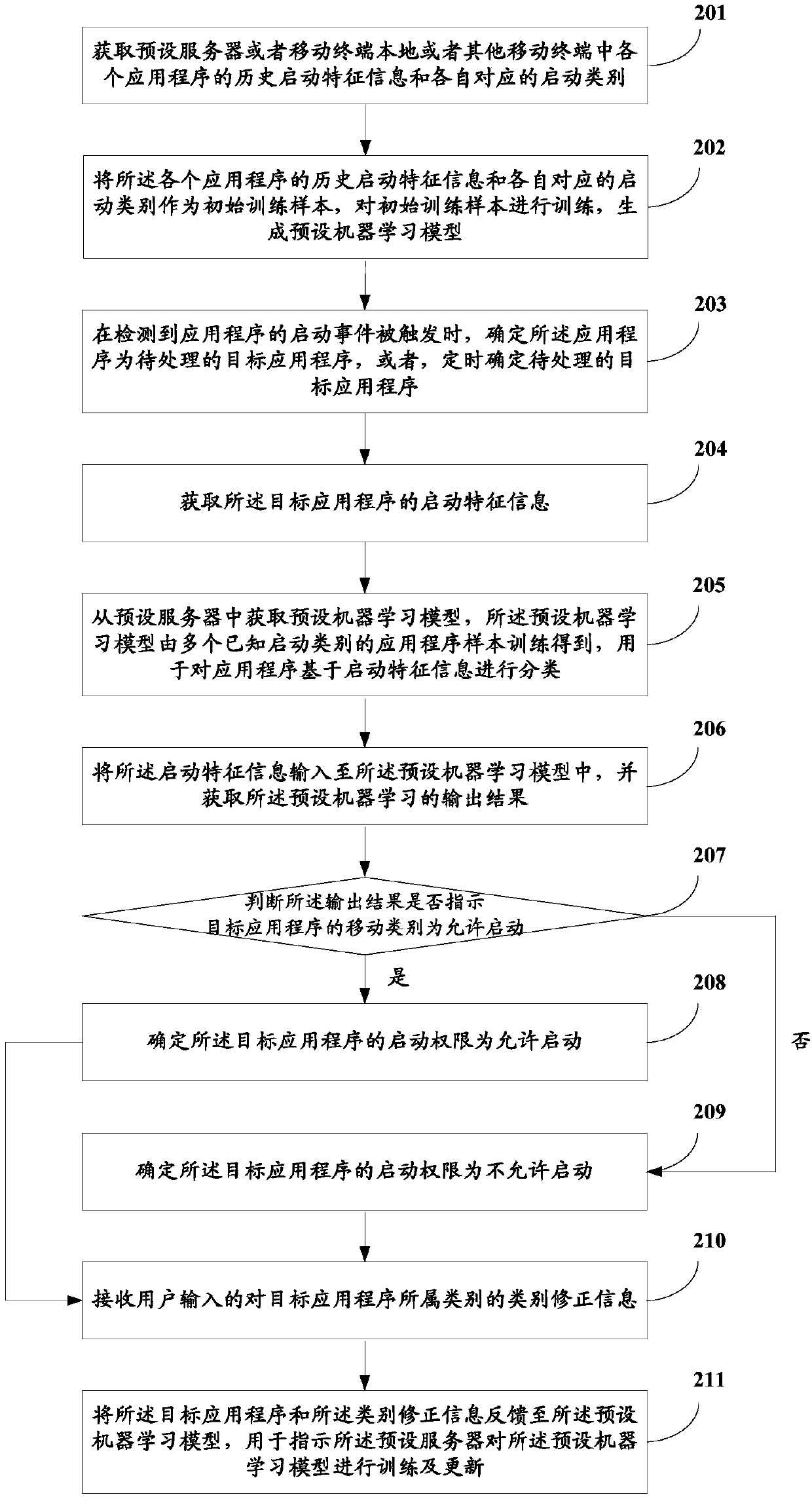

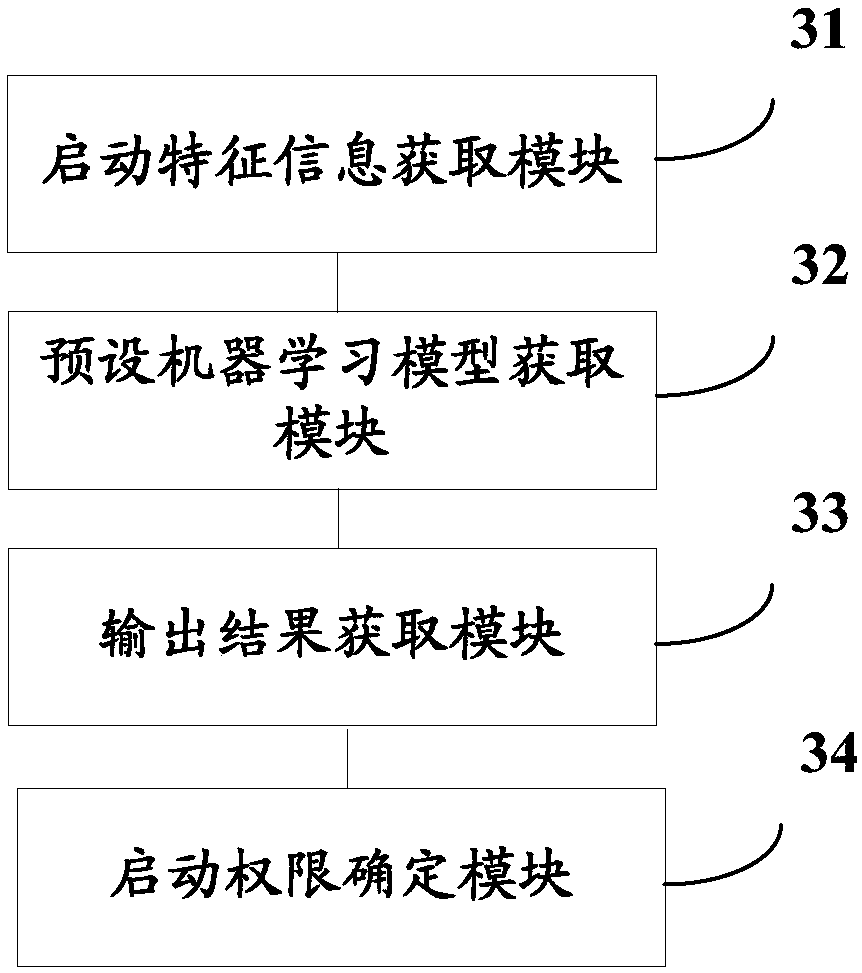

Application startup control method and apparatus, storage medium and mobile terminal

InactiveCN107944259AConsume resourcesConsumption flowComputer security arrangementsProgram loading/initiatingApplication softwareComputer engineering

Embodiments of the invention disclose an application startup control method and apparatus, a storage medium and a mobile terminal. The method comprises the steps of determining a to-be-processed target application, and obtaining startup feature information of the target application; obtaining a preset machine learning model, wherein the preset machine learning model is obtained by training application samples of multiple known startup types and is used for classifying applications based on the startup feature information; inputting the startup feature information to the preset machine learningmodel, and obtaining an output result of preset machine learning; and according to the output result, determining a startup permission of the target application. According to the technical scheme provided by the application startup control method and apparatus, the startup permissions of the applications are reasonably controlled according to startup features of the applications based on the machine learning model, so that the resource and flow consumption of the mobile terminal caused by self-startup or associated startup of a few abnormally started applications can be effectively prevented.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

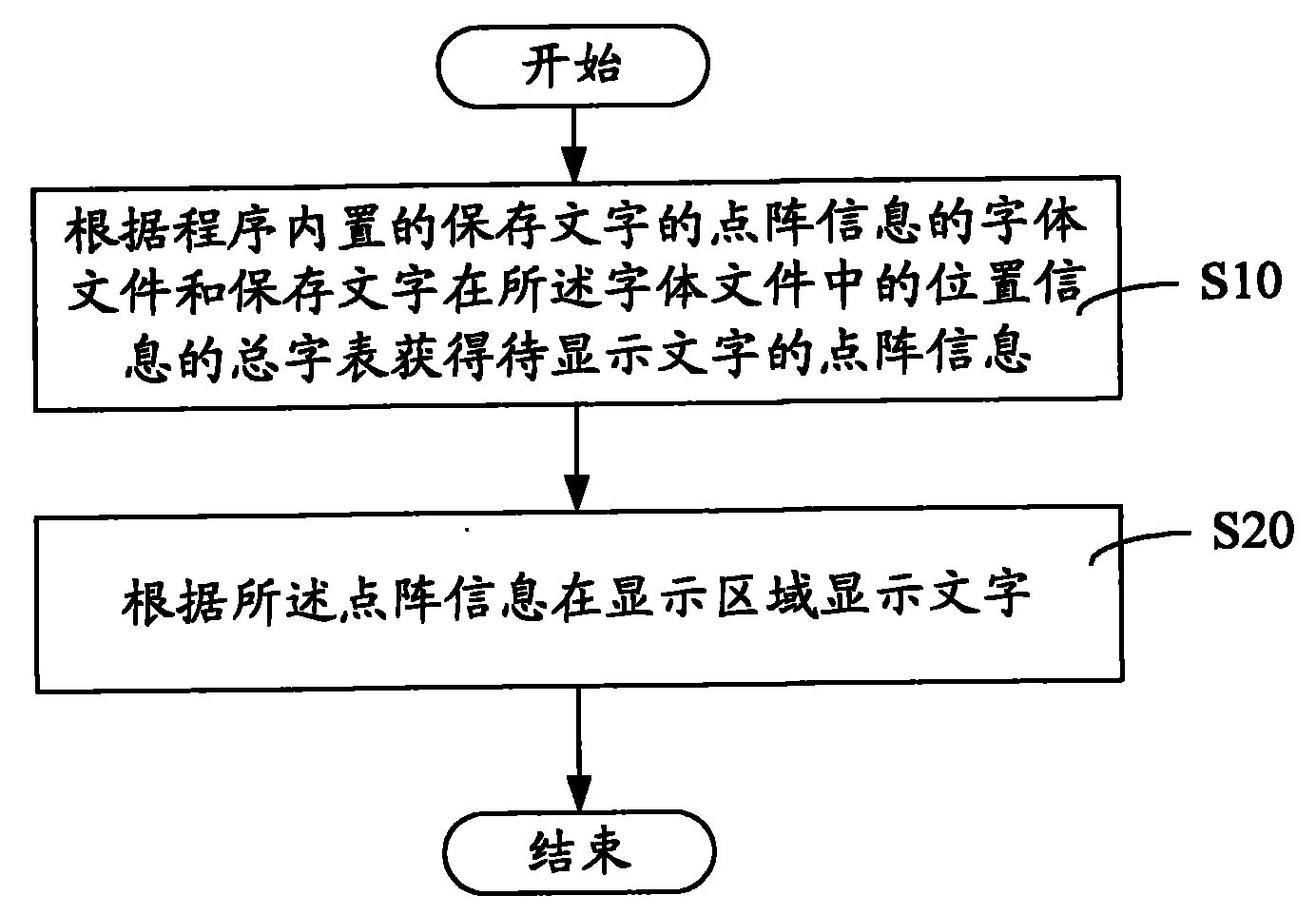

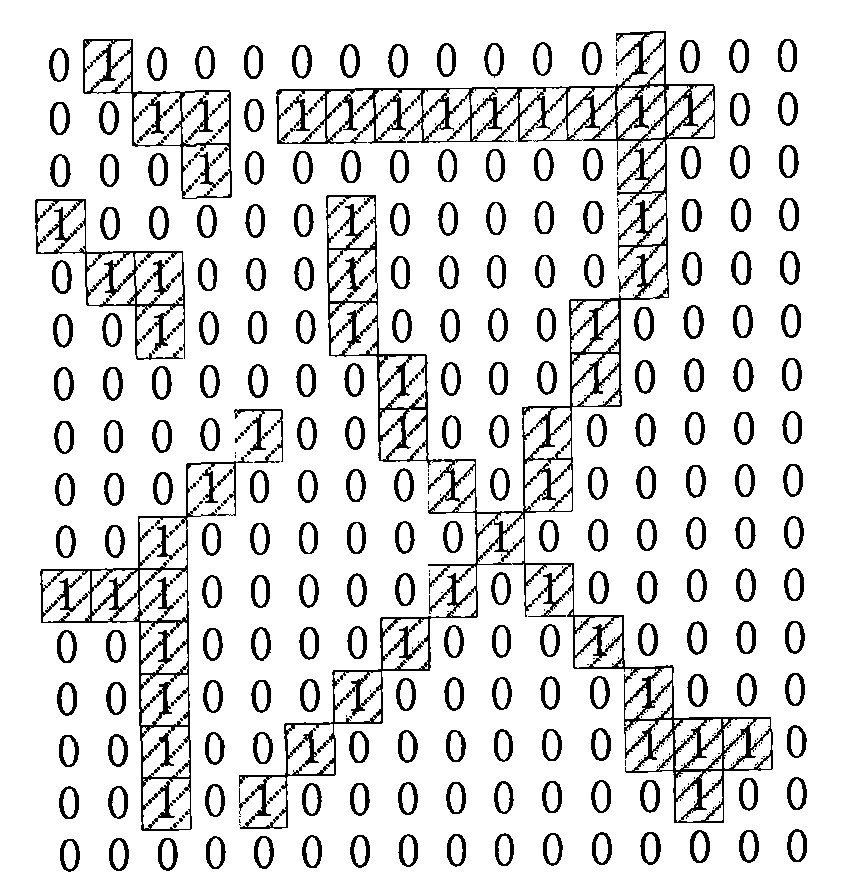

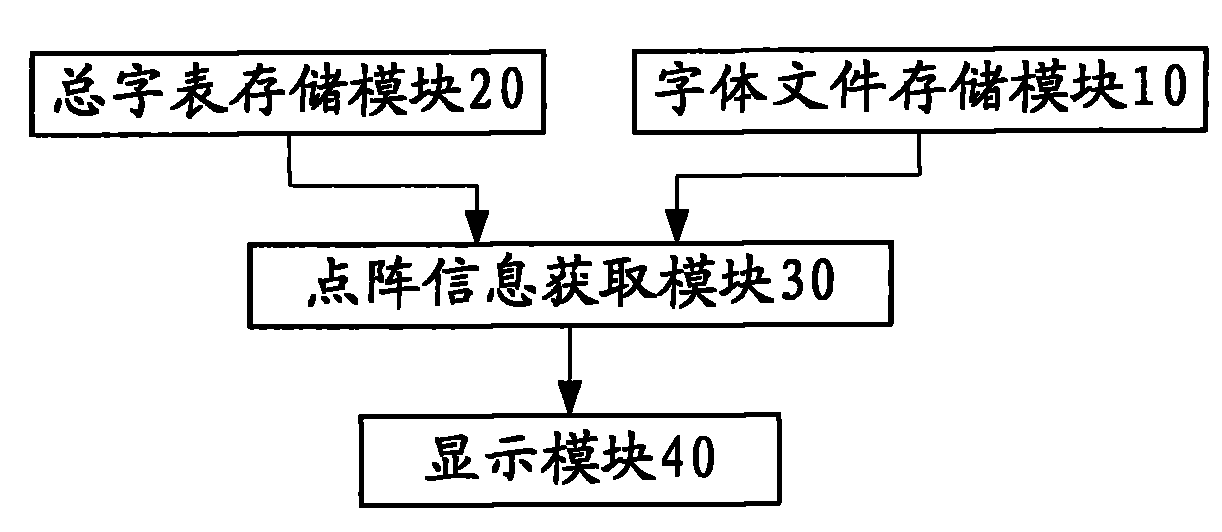

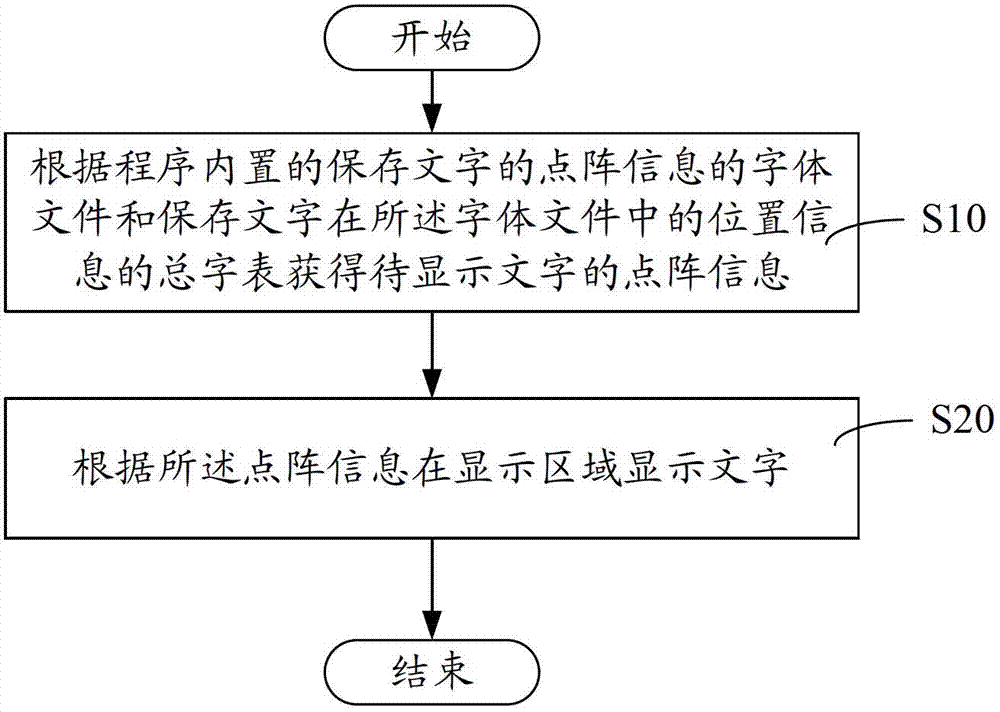

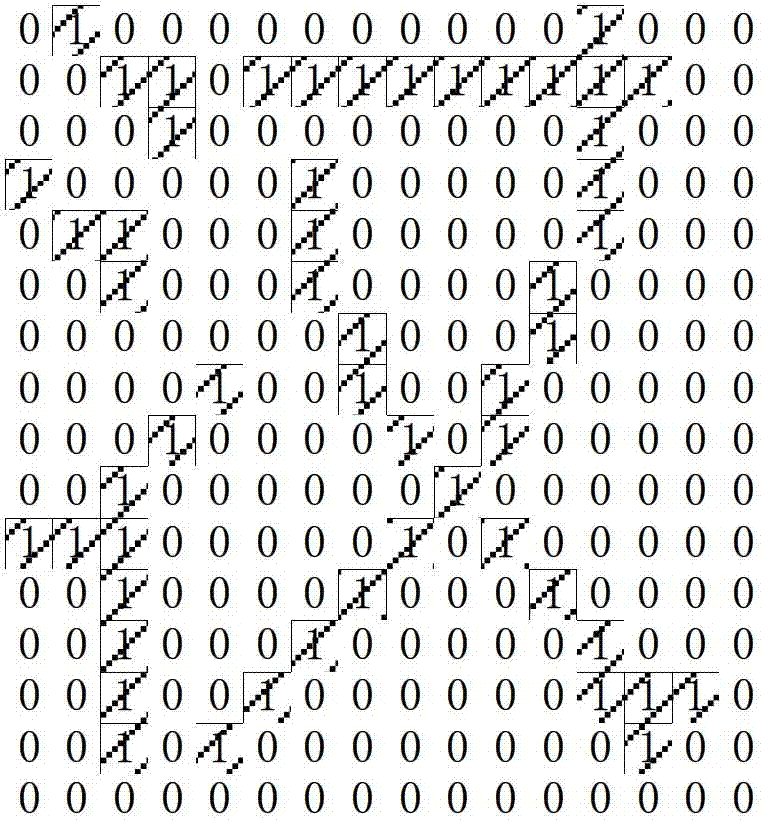

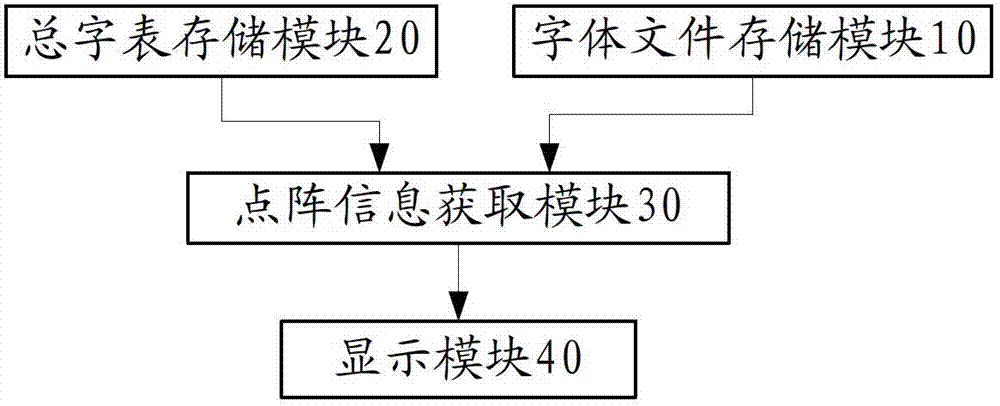

Method and system for displaying characters

ActiveCN102169423AIncrease flexibilitySave running memoryCathode-ray tube indicatorsDigital output to display deviceComputer graphics (images)Theoretical computer science

The utility model relates to a method for displaying characters, which belongs to the technical field of computers, and comprises the steps as follows: lattice information of characters to be displayed is obtained according to a typeface file used for keeping lattice information of characters in a program and a whole character table keeping the position information of the characters in the typeface file; and the characters are displayed according to the lattice information of the characters to be displayed. Besides, the invention also relates to a system for displaying characters according tothe method. In the method and the system, a program developer can use self-defined typefaces through using the built-in typeface file, and the flexibility on the aspect of using different styles of typefaces is improved. Moreover, compared with the characters displayed through pictures, displaying the characters by using the lattice information of the characters can greatly reduce a running memory, and can display the unknown typefaces in advance in real time according to the typeface file.

Owner:TENCENT TECH (BEIJING) CO LTD

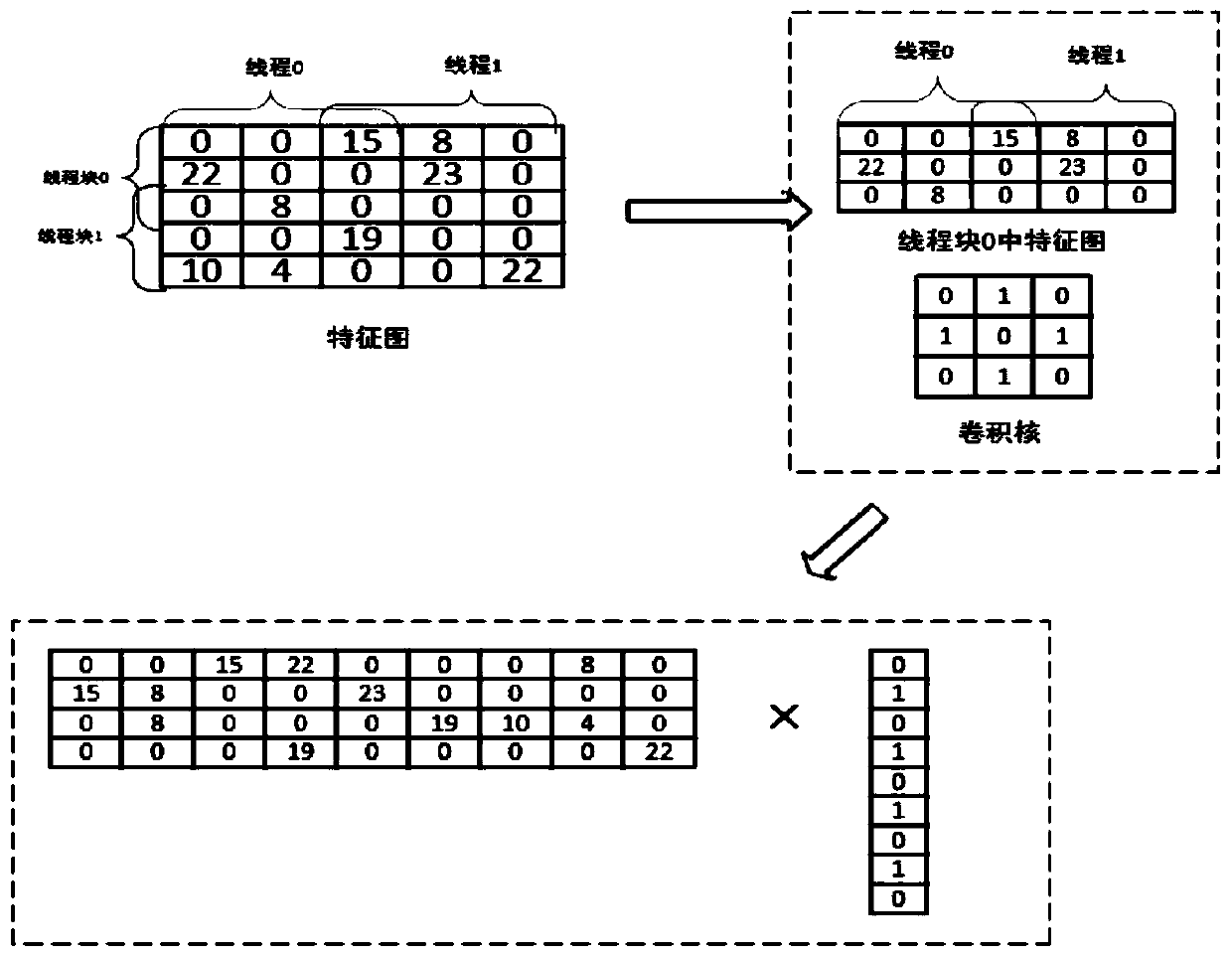

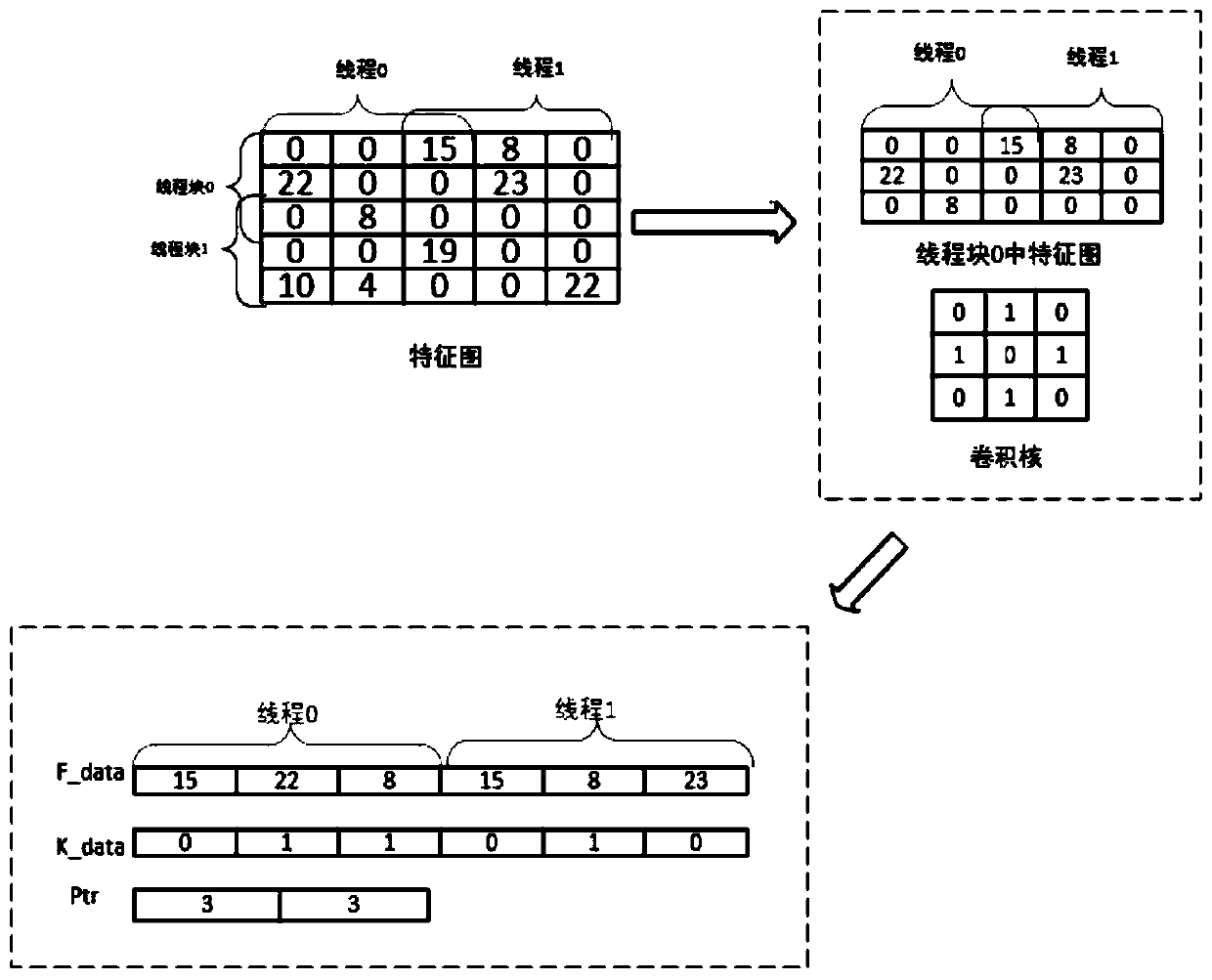

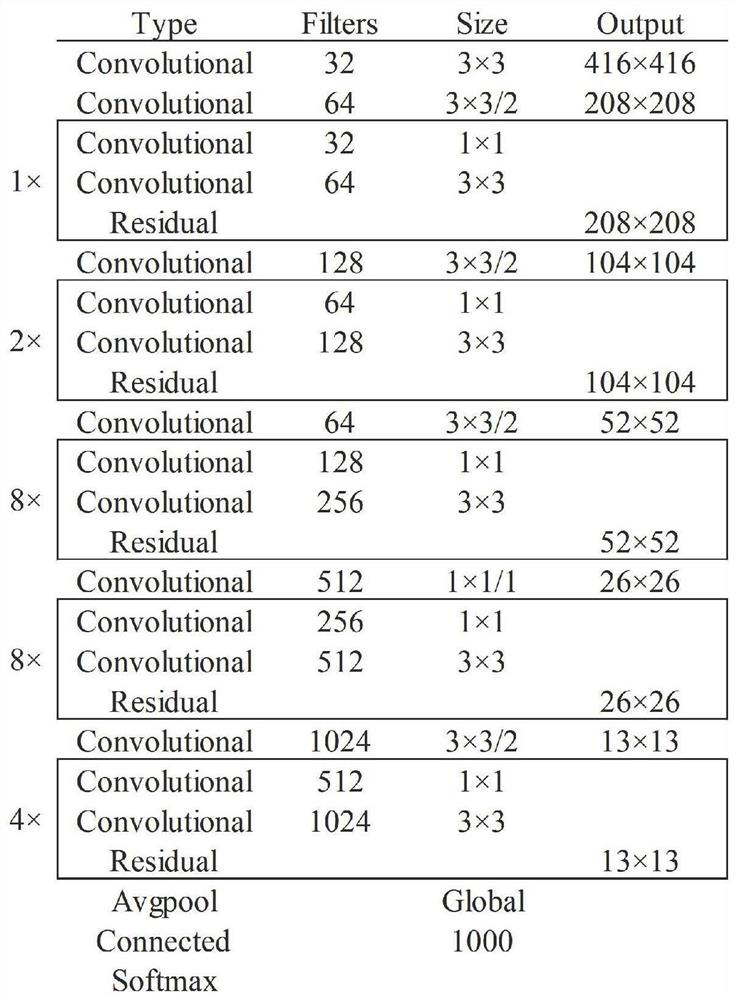

Data classification method and system based on convolutional neural network, medium and equipment

ActiveCN110909801AReduce training timeReduce memory consumptionCharacter and pattern recognitionNeural architecturesData setConcurrent computation

The invention provides a data classification method and system based on a convolutional neural network, a medium and equipment. The data classification method comprises the steps: carrying out the preprocessing of obtained classification data, and constructing a data set; constructing a convolutional neural network, wherein the convolutional neural network at least comprises a convolutional layerused for extracting local features, and the convolutional layer compresses a feature matrix, and sparse matrix vector multiplication operation is performed on the generated sparse matrix on a graphicprocessing unit, and data in a data set is utilized to train the convolutional neural network; and preprocessing the to-be-classified data, inputting the preprocessed to-be-classified data into the trained convolutional neural network model, and outputting a data classification result. According to the data classification method, the feature matrix of the convolutional layer is compressed, and parallel computation is performed on the GPU, so that the memory consumption and zero value computation in the computation process are reduced, and the training time and memory consumption of the neuralnetwork are reduced.

Owner:SHANDONG NORMAL UNIV

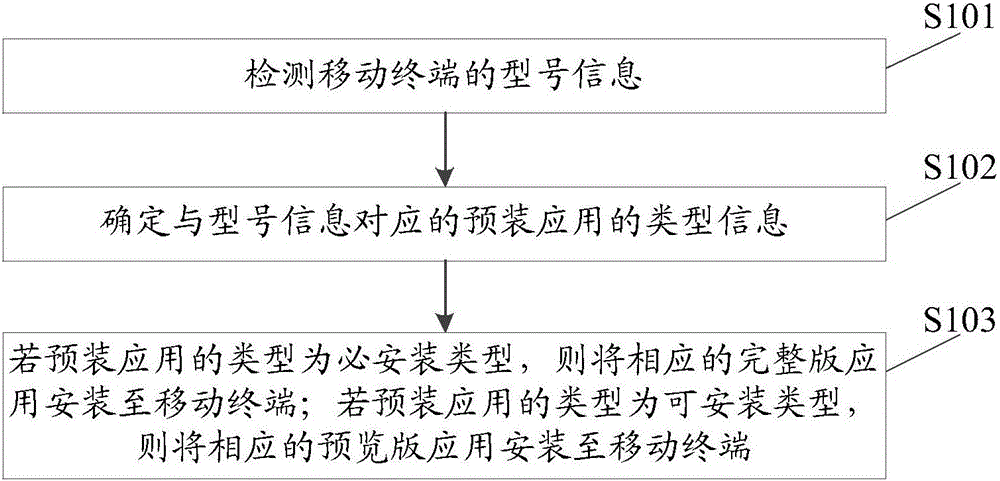

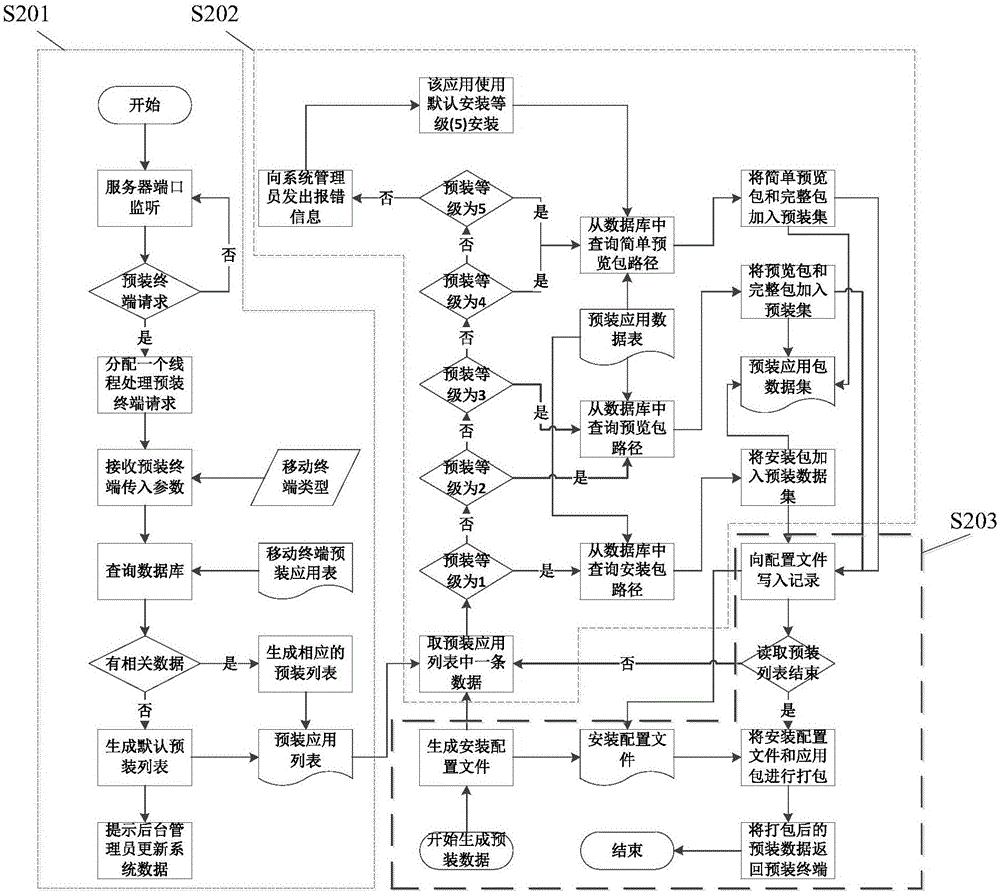

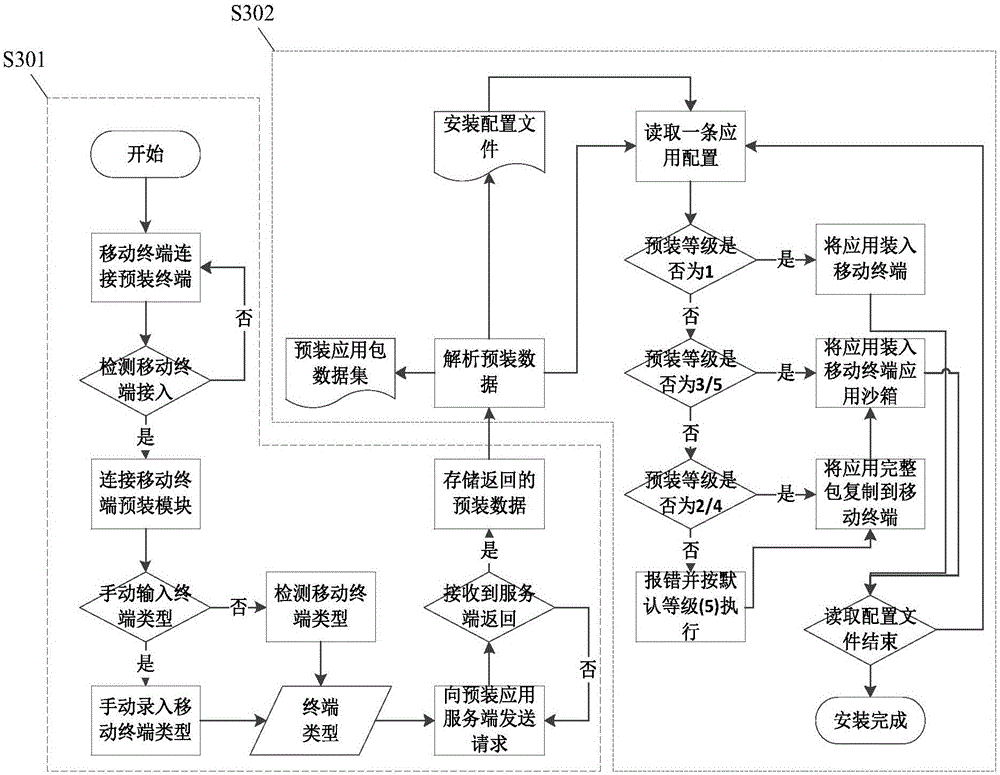

Installation method and device for preinstalled application of mobile terminal

ActiveCN106775832AIncrease speedIncrease storage spaceProgram loading/initiatingSoftware deploymentModel NumberOperating speed

The invention discloses an installation method for a preinstalled application of a mobile terminal. The installation method comprises the steps as follows: detecting model information of the mobile terminal; determining type information of the preinstalled application corresponding to the model information; if the type of the preinstalled application is the type of installation, the corresponding full-version application is installed to the mobile terminal; if the type of the preinstalled application is the installable type, the corresponding preview application is installed to the mobile terminal. It can be seen that in this scheme, the type of the preinstalled application is determined according to the type of the mobile terminal. If the preinstalled application type is the installable type, the preview application is installed to the corresponding mobile terminal. The preview application can not only realize main functions of the full-version application, but also reduce the occupied running memory and storage capacity compared to the full-version application, accordingly, the operating speed of the mobile terminal is increased, and the system performance is improved; the invention further discloses an installation device of the preinstalled application of the mobile terminal, and the installation device can also realize the technical scheme.

Owner:YULONG COMPUTER TELECOMM SCI (SHENZHEN) CO LTD

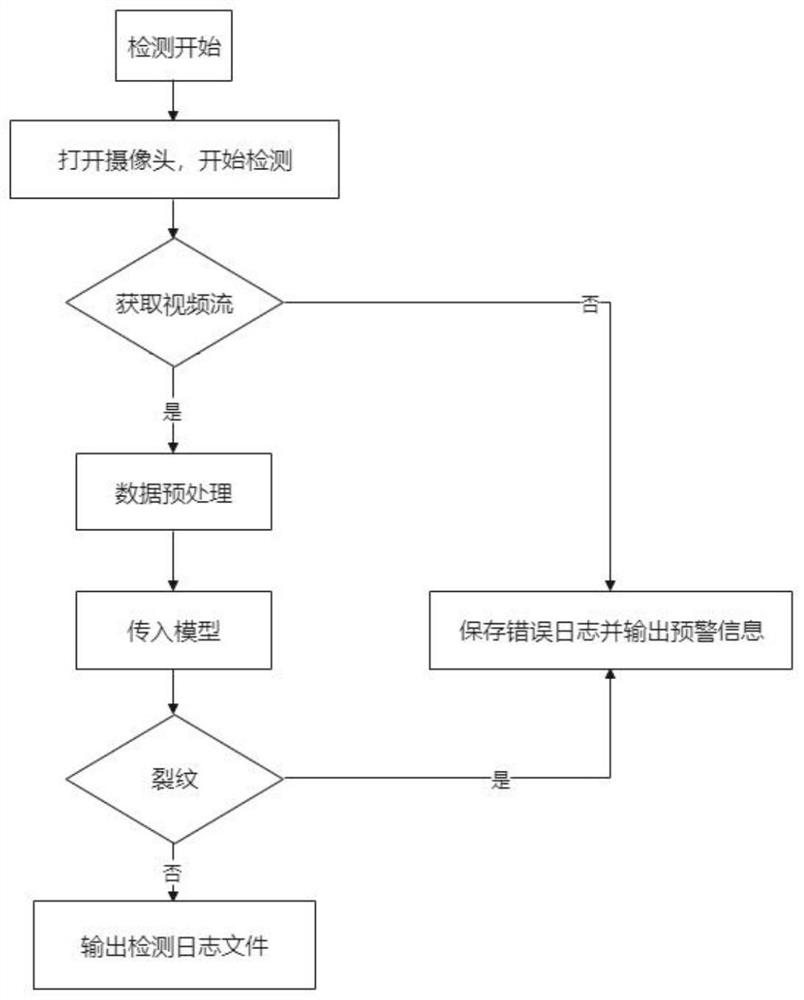

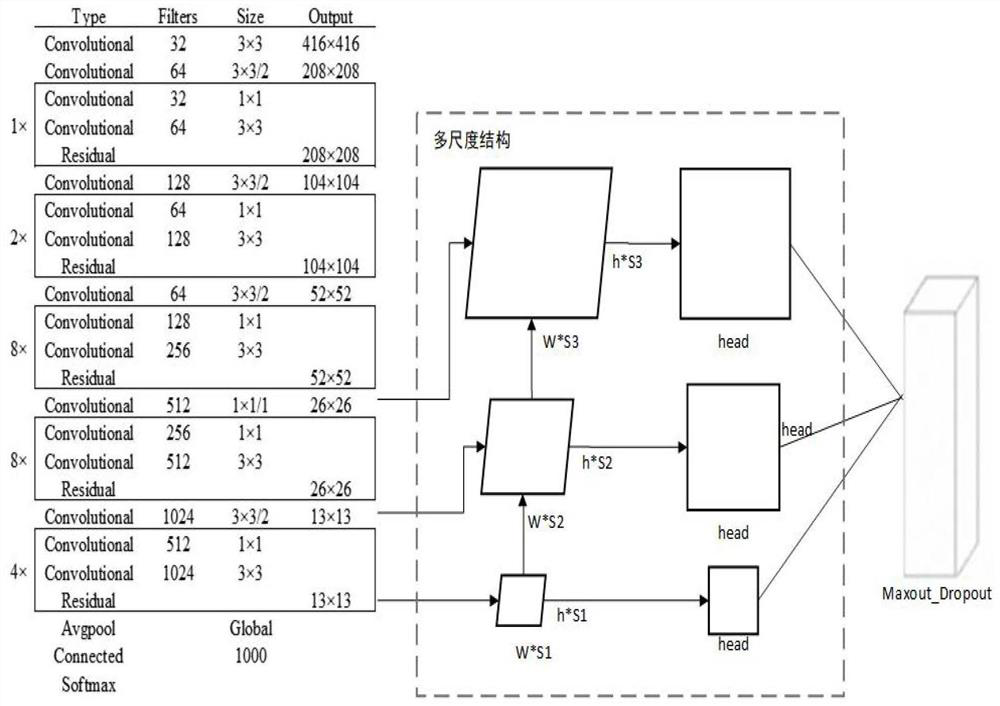

Pipeline defect intelligent detection method based on image processing and deep learning, and application thereof

InactiveCN113379737ADistinctive featuresEasy to detectImage enhancementImage analysisImaging processingFeature extraction

The invention discloses a pipeline defect intelligent detection method based on image processing and deep learning, and application thereof. The intelligent detection method comprises the following steps: carrying out preprocessing including edge detection on pipeline image data, inputting the preprocessed image into a trained detection model, and carrying out defect detection, wherein the detection model is constructed based on a Darknet53 backbone network and a multi-scale feature extraction network. According to the detection method, different defects of the pipeline can be accurately recognized and detected, the model meeting the industrial application level is obtained, the detection efficiency is high, and the environment universality is high.

Owner:SOUTHWEST PETROLEUM UNIV

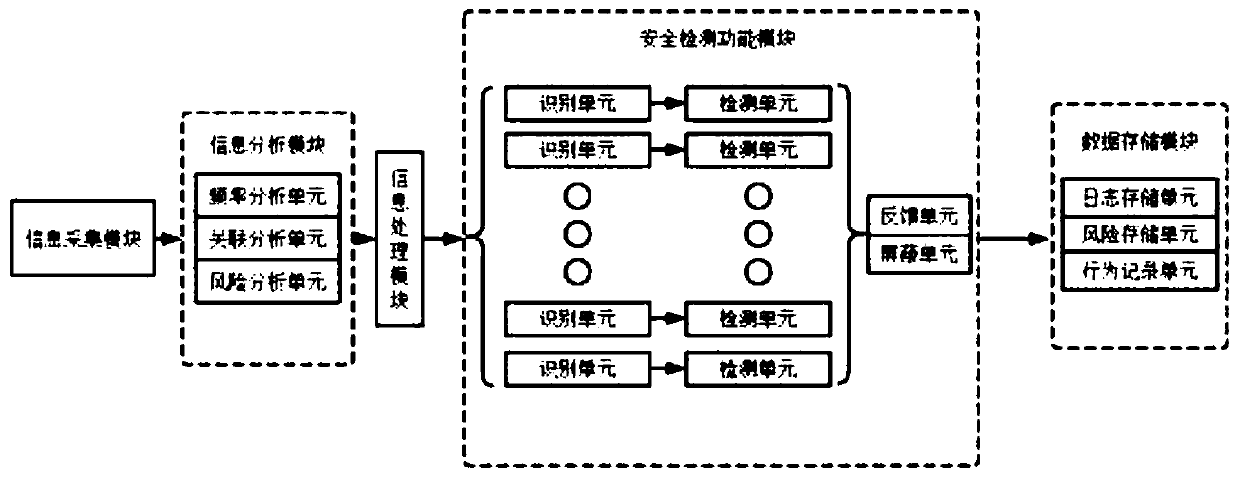

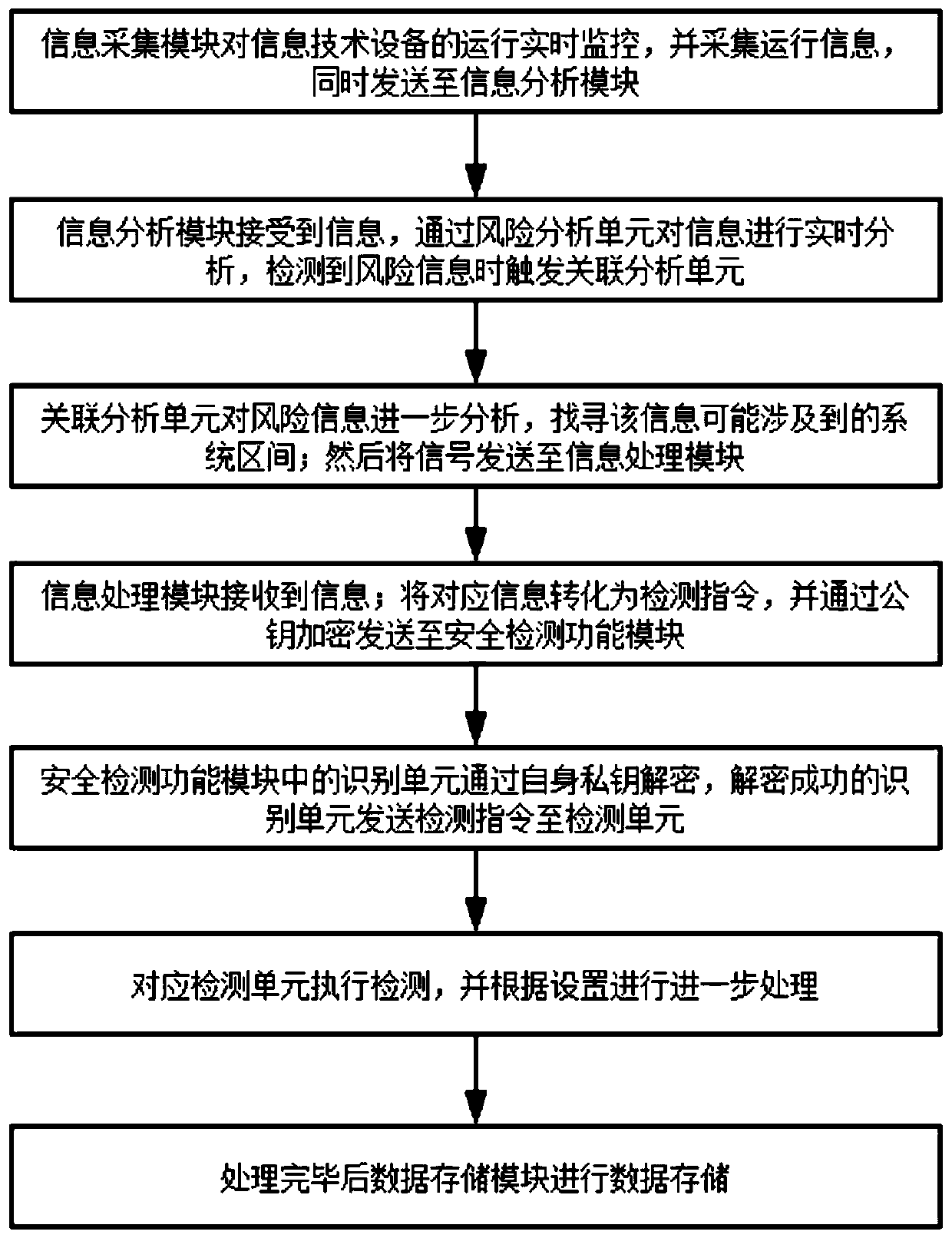

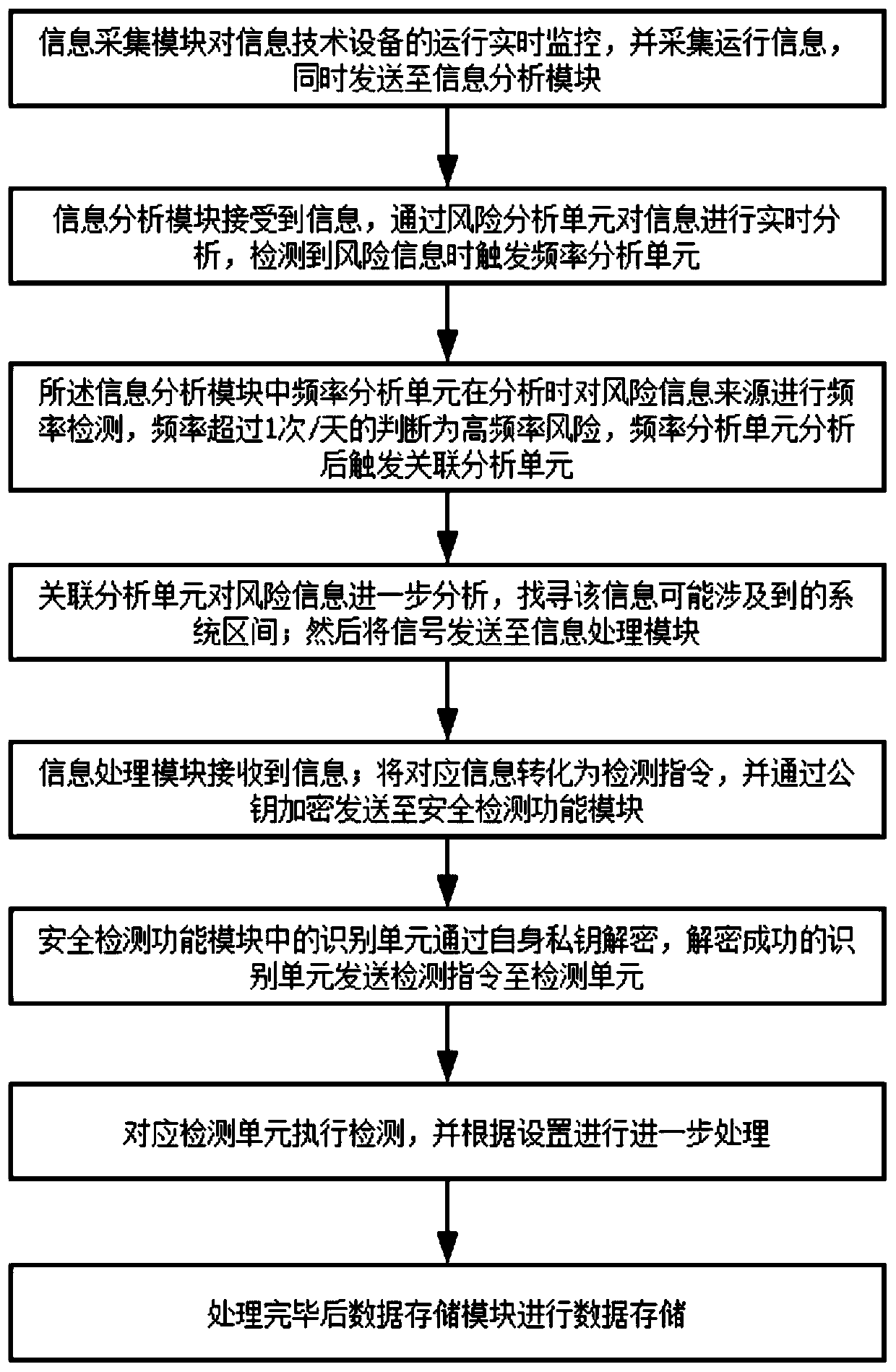

Information technology equipment safety detection system and detection method thereof

InactiveCN111552602AEnsure safetySave running memoryHardware monitoringDigital data protectionInformation processingInformation analysis

The invention discloses an information technology equipment safety detection system and a detection method thereof, which relate to the field of equipment safety detection. In order to formulate a more effective detection scheme according to the operation condition and the information source of the equipment, the detection system specifically comprises an information acquisition module, an information analysis module, an information processing module, a safety detection function module and a data storage module, wherein the information analysis module is respectively connected with the information acquisition module and the information processing module; the safety detection function module is connected with the information processing module and the data storage module. The detection method specifically comprises the following steps that the information acquisition module monitors the operation of the information technology equipment in real time, acquires operation information and sends the operation information to the information analysis module. Information technology equipment can be monitored in real time, and meanwhile, the risk information is analyzed, so that the detectionwork is carried out in a targeted manner, the system operation memory is saved, and the safety of the operation environment is guaranteed.

Owner:广东鹄志人才服务有限公司

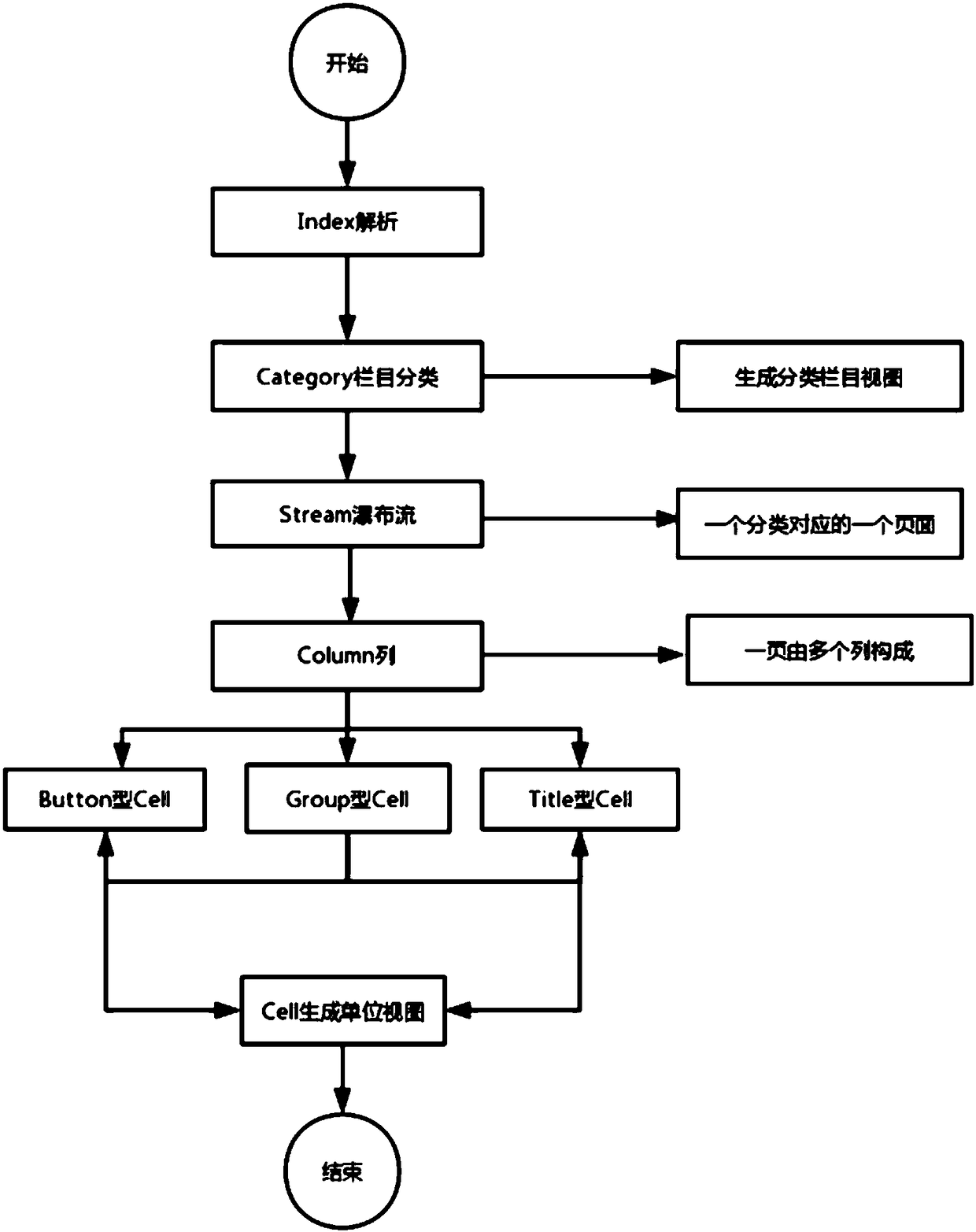

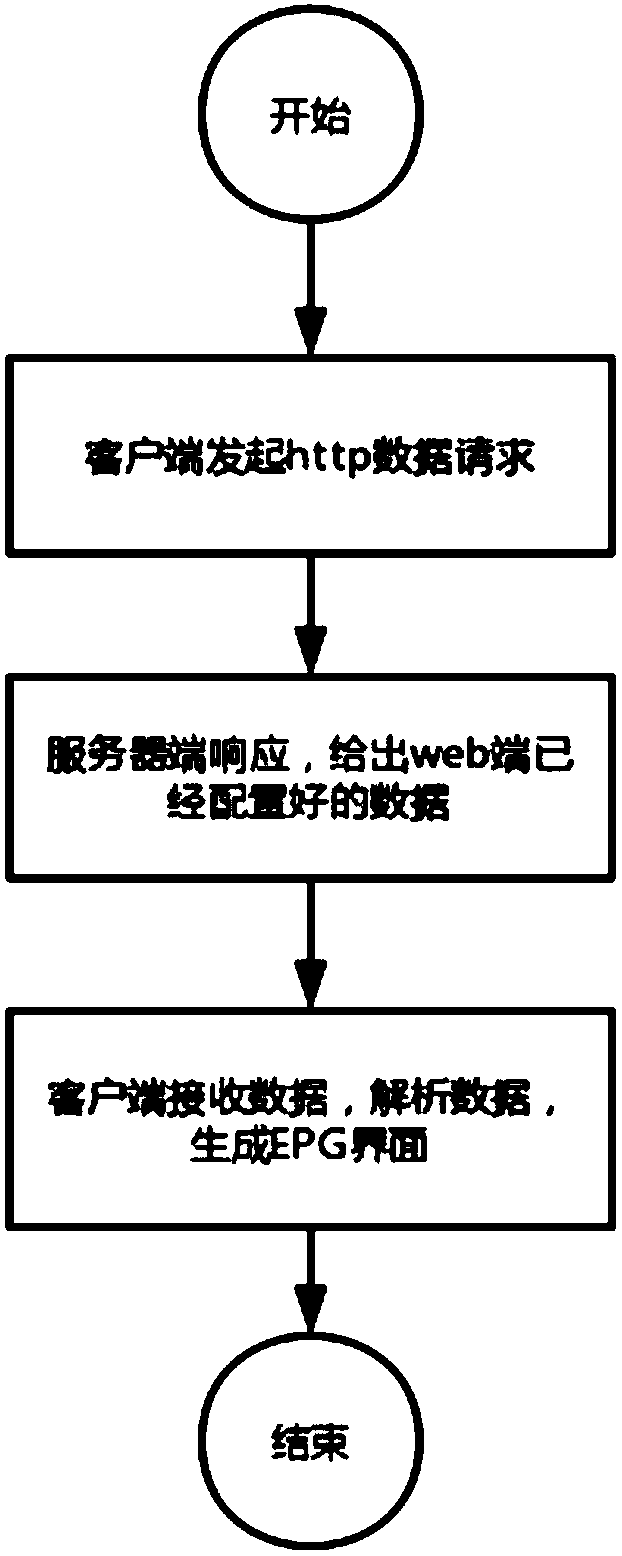

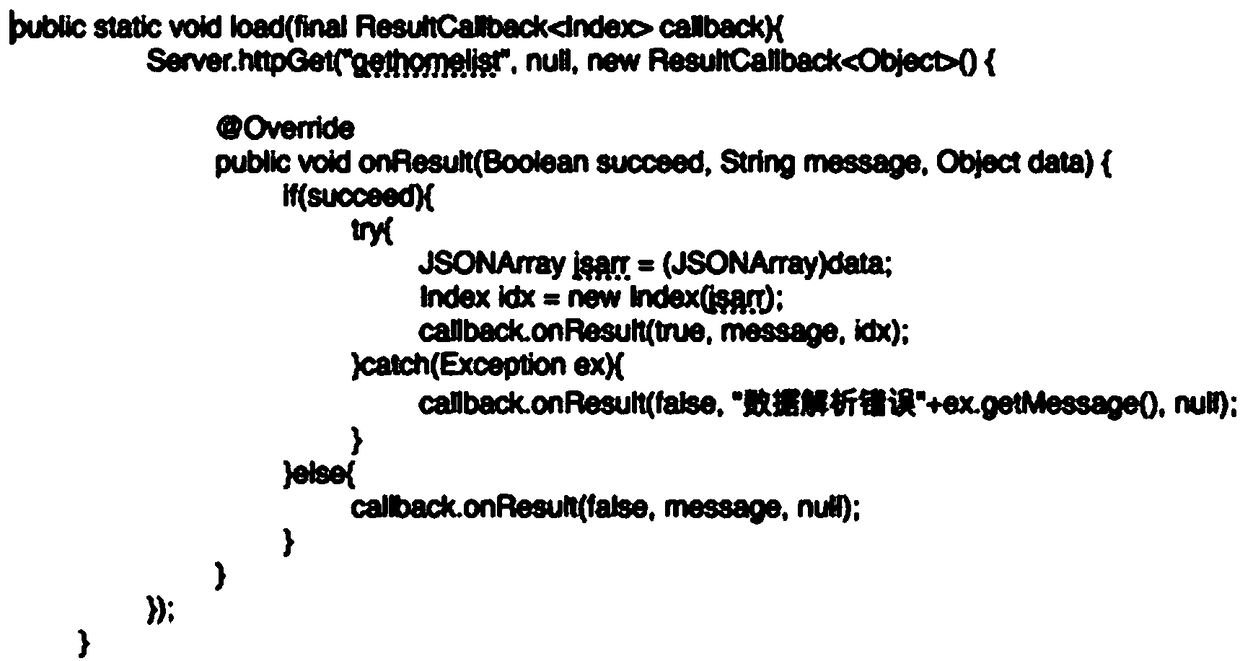

Method for automatically configuring and generating OTT platform EPG interface

InactiveCN108337564AImprove experienceExpress interactionSelective content distributionGeneration processHome page

The invention discloses a method for automatically configuring and generating an OTT platform EPG interface. The method comprises the following steps: a client initiates an http data request, a serverresponds to the http data request, and a background configures data necessary for the EPG interface, wherein the data are configured according to layers, after receiving the data, the client parses the data layer by layer and fills the data layer by layer to generate a view, recovery is performed by a memory in a data parsing and view generation process to perform optimized operation, and the client comprises a background modeling module, a data parsing and filling module and a memory recycling module. According to the method, the most complex function is achieved in the simplest way, and better and more experience is brought to users by dynamic configuration. The immature fixed EPG homepage is discarded, and we hope to achieve a very high level of realization, simplicity and simplicity without losing the technical level.

Owner:多彩贵州印象网络传媒股份有限公司

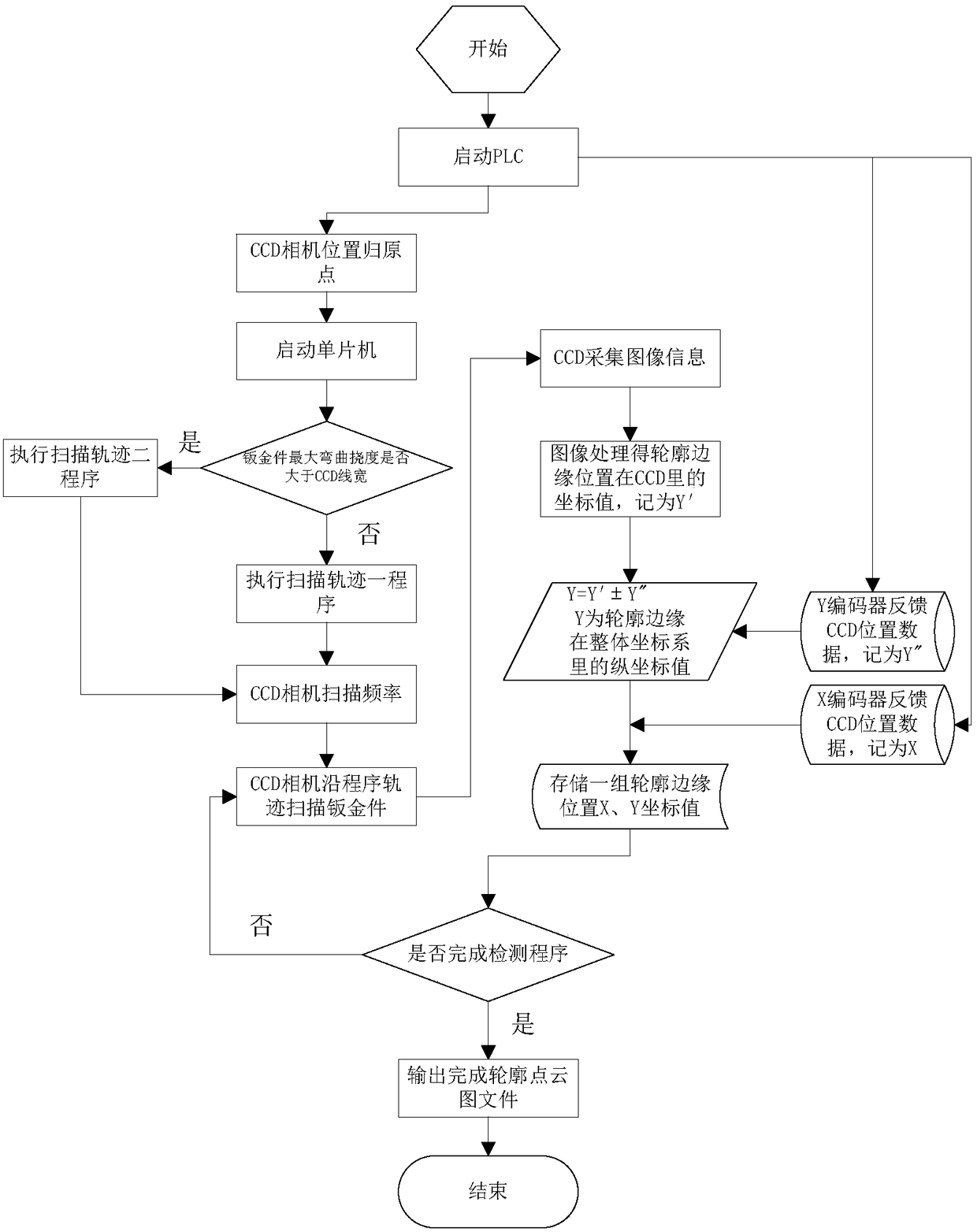

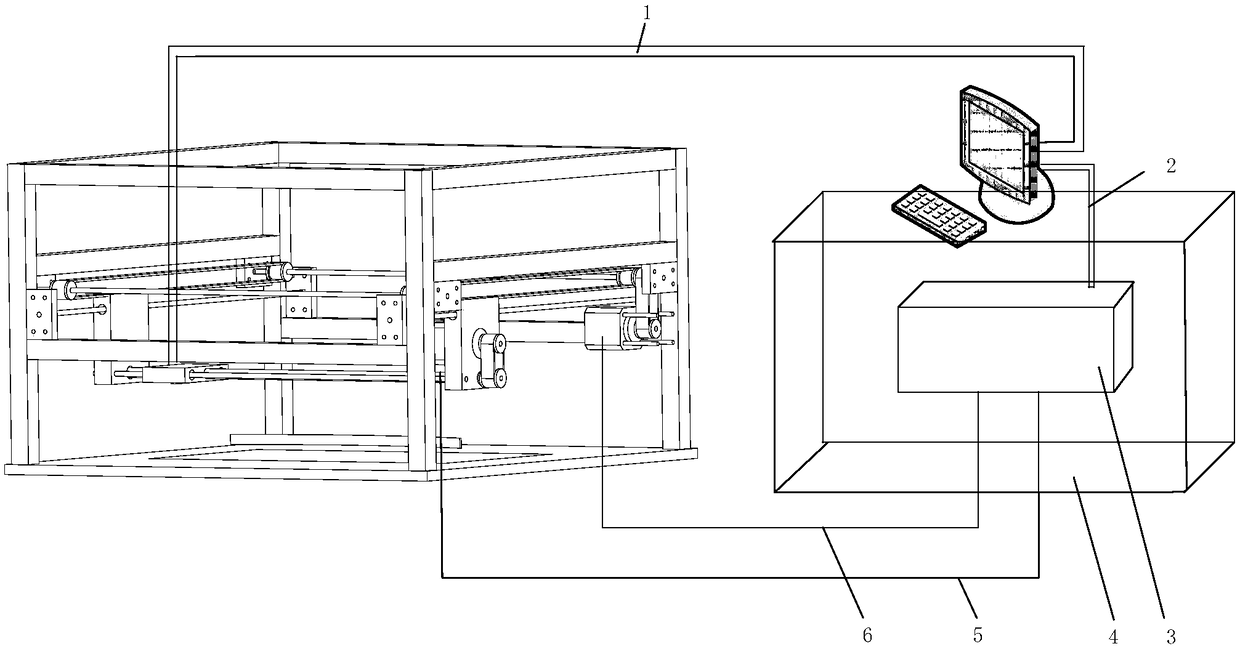

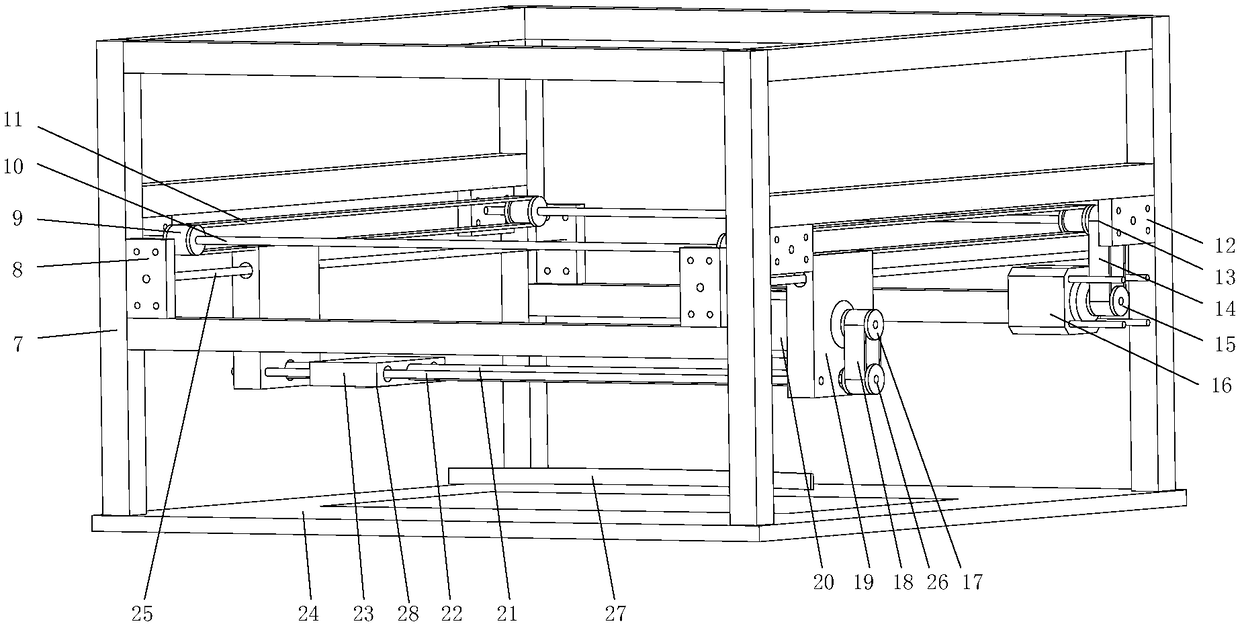

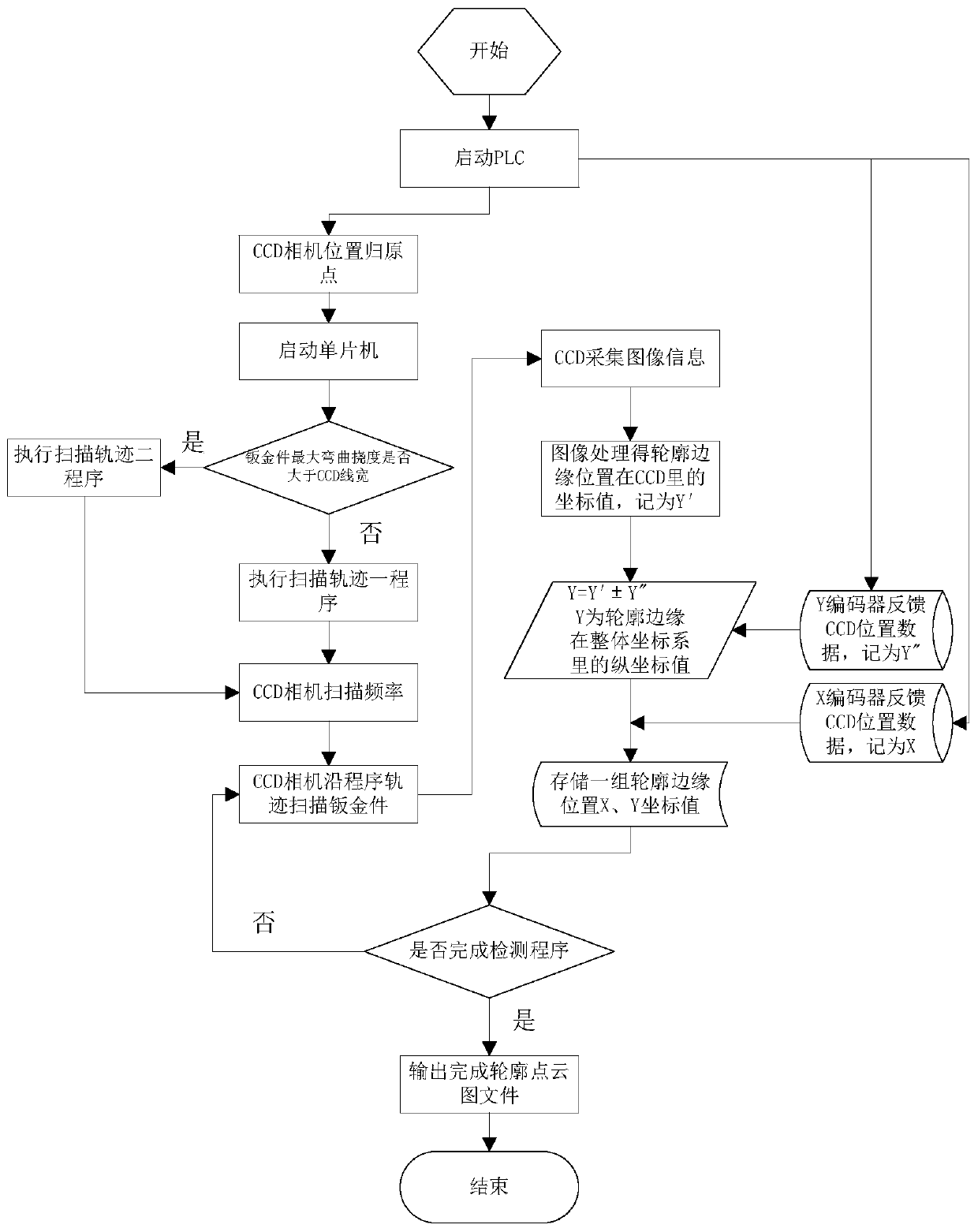

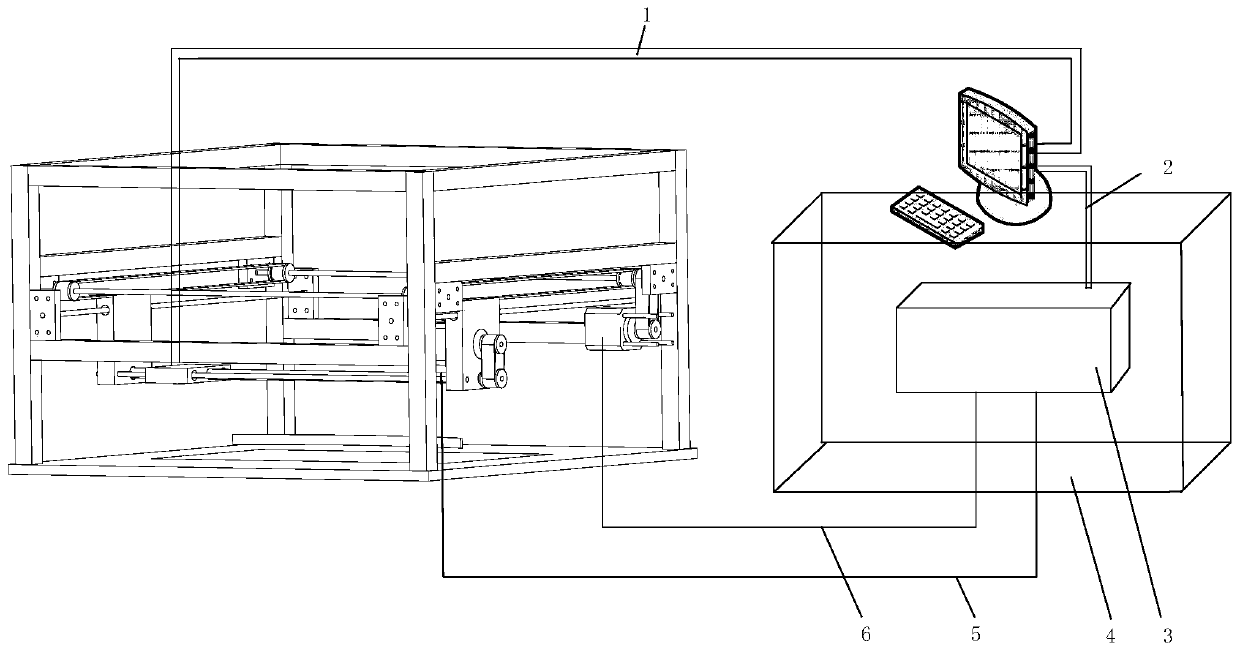

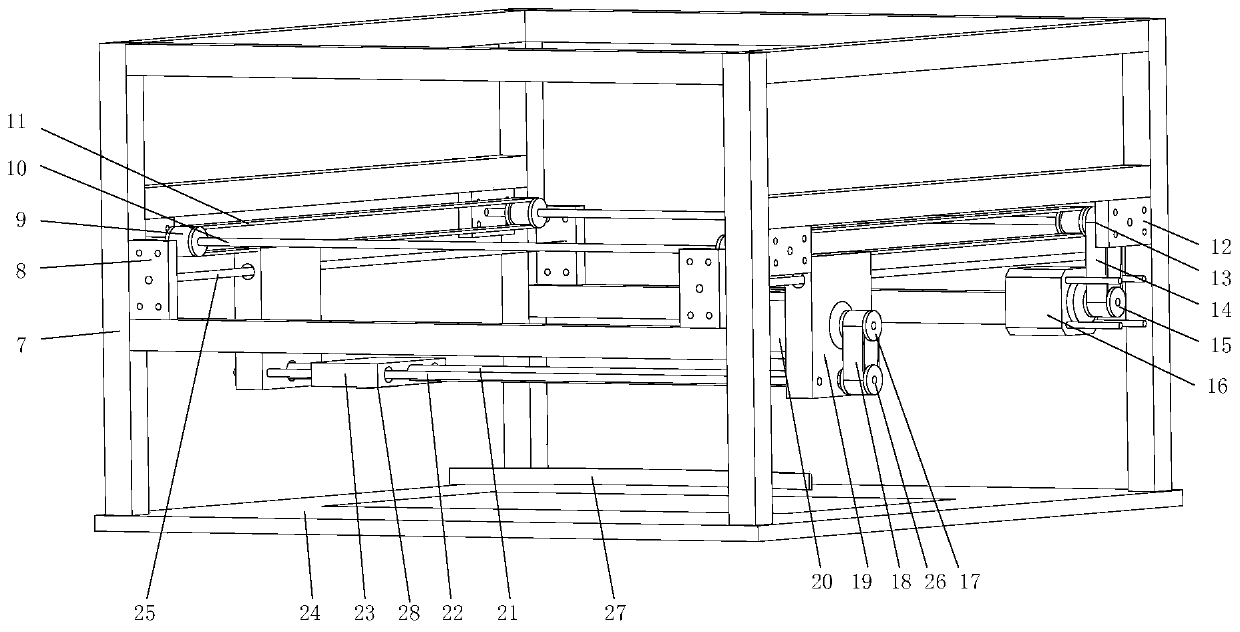

Device and method for detecting curved contour of section of planar bent sheet metal part

ActiveCN108592819AHigh sensitivityHigh measurement accuracyUsing optical meansMicrocomputerPoint cloud

Provided is a device for detecting the curved contour of a section of the planar bent sheet metal part. The device comprises a mechanical device and a control device. The control device comprises a control box, a PLC, a single-chip microcomputer and a computer. The mechanical device comprises a frame, an X-direction translation module, a Y-direction translation module and a linear array CCD camera. A detecting method adopting the detecting device mainly comprises the steps the contour position information collected by the linear array CCD camera and Y-module coder data of the mechanical deviceare combined and serve as a Y coordinate value of a metal plate contour two-dimensional diagram after data processing, position data fed back by a X-module servo motor coder in the mechanical deviceis adopted as an X coordinate value of the metal plate contour two-dimensional diagram, metal plate contour circulating scanning and contour point data collection are completed through control of a driving program, and a two-dimensional point cloud file related to the curved contour of the sheet metal part is obtained after upper computer data processing is carried out. The device is automatic, efficient and cheap and can extract contour data fast and conveniently.

Owner:YANSHAN UNIV

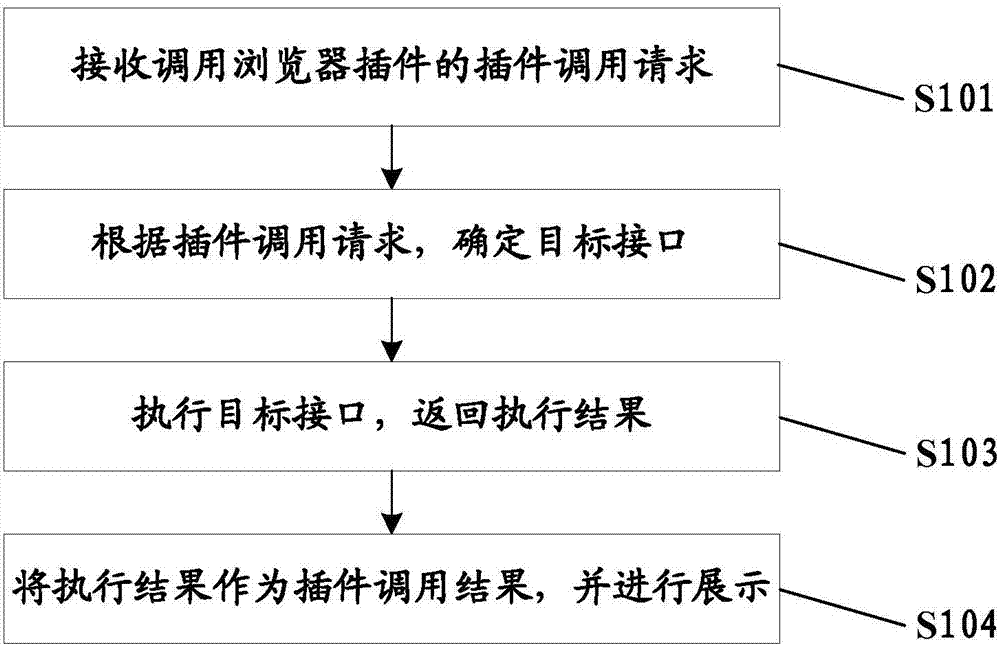

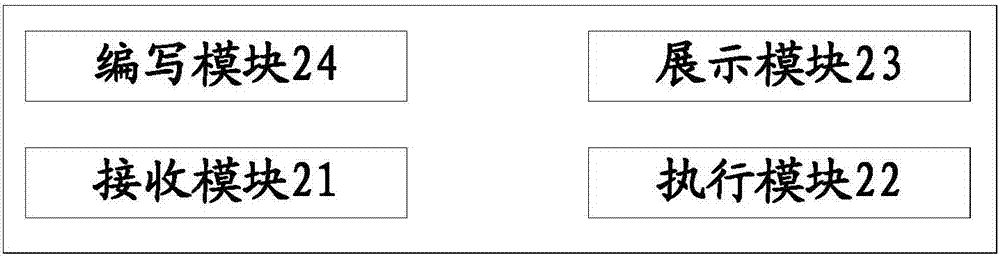

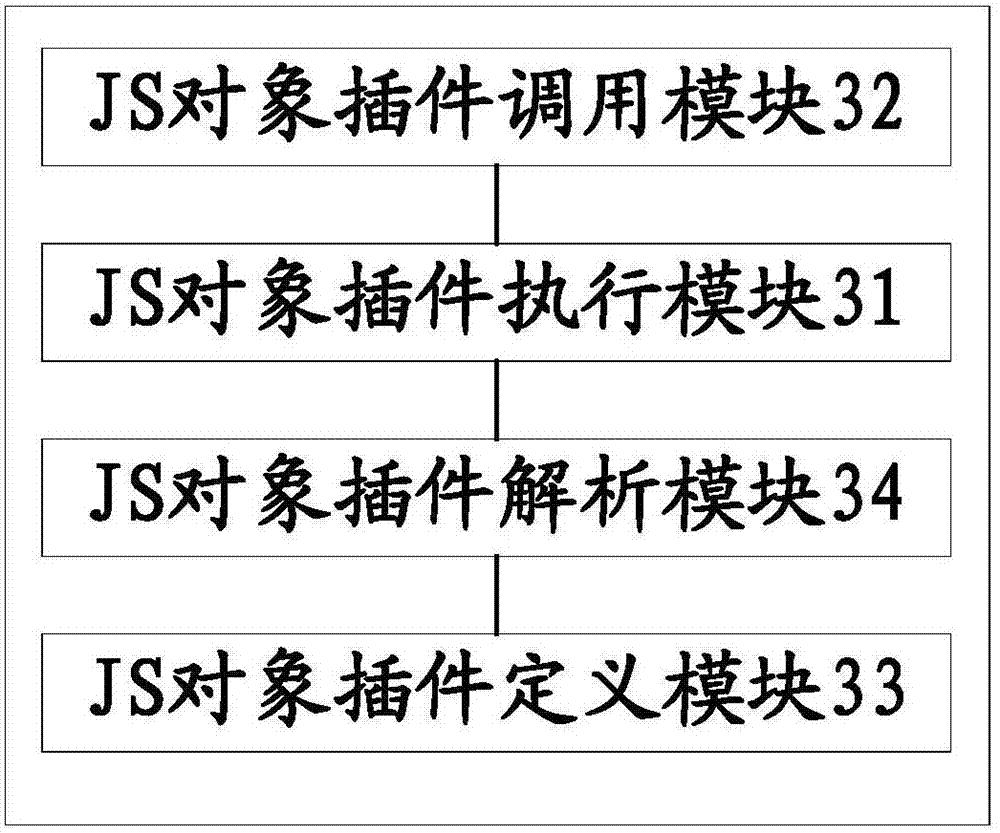

Interface implementation method and device and set-top box

InactiveCN107547944ARun fastReduced development effortProgram loading/initiatingSelective content distributionSoftware engineeringWorkload

The embodiment of the invention provides an interface implementation method and device and a set-top box. The method comprises the steps that a plugin calling request for calling a browser plugin is received; a target interface needing to be executed is determined according to the plugin calling request; the target interface is executed, and an execution result is returned; and the execution result is taken as a plugin calling result and displayed. According to the novel interface implementation mode, a JS interface is taken as the browser plugin, and a corresponding JS interface function is achieved by calling the browser plugin; and compared with the prior art, the method has the advantages that great progress is achieved, an obvious effect is achieved, the development workload of the JSexpansion interface and the memory occupied during browser operation are reduced, the working efficiency of developers is improved, the browser operation speed is increased, the problem that an existing browser JS expansion interface needs to recompile a browser code is solved, and the use experience of a user is enhanced.

Owner:ZTE CORP

Picture generation method based on picture editing of mobile operating system

InactiveCN111091608ASave running memoryEfficient mapping3D-image renderingEditing/combining figures or textComputer graphics (images)Engineering

The invention relates to a picture generation method based on picture editing of a mobile operating system. Editing and generation of a high-definition picture of a mobile terminal are achieved through foreground and background separated rendering. The method comprises the following steps: firstly, loading a preview obtained by reducing an original high-definition image, and submitting the previewto an editing view for rendering; the user edits the rendered preview to generate edit element information, and the edit elements are rendered according to the equal-ratio reduced size, so that the effect of saving the running memory during editing is achieved; when the picture is generated, the original picture of the high-definition picture is rendered at the background, and then rendering is performed according to the original size of the editing element so as to generate the high-definition picture.

Owner:GAODING XIAMEN TECH CO LTD

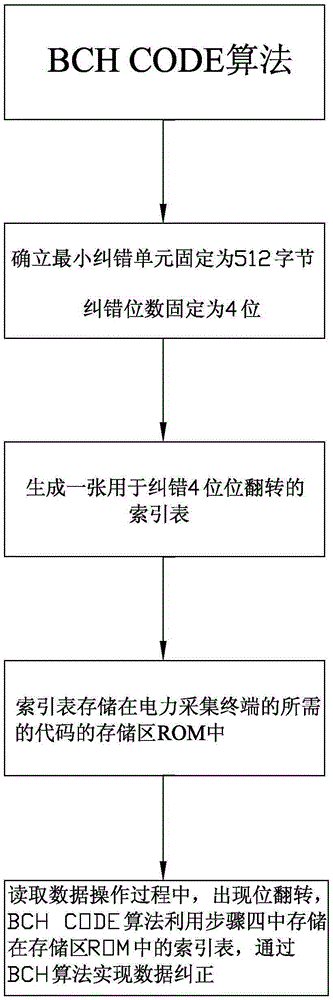

Error correction method used for NAND-FLASH-adopted electric power acquisition terminal

ActiveCN105242982AReduce capacityReduce operating loadRedundant data error correctionData operationsMinimum error correction

The invention discloses an error correction method used for a NAND-FLASH-adopted electric power acquisition terminal, which comprises the following steps: determining to adopt a BCH (Bose, Ray-Chaudhuri and Hocquenghem) CODE algorithm to realize data error correction; in the BCH CODE algorithm, determining that a minimum error correction unit fixedly has 512 bytes and 4 error correction bits; according to a rule that the minimum error correction unit fixedly has 512 bytes and 4 error correction bits, generating an index table used for error correction bit flipping; storing the index table in a memory area ROM (Read Only Memory) of codes required by the electric power acquisition terminal; carrying out a data reading operation on Nand Flash by an application program on the electric power acquisition terminal, and utilizing the index table stored in the memory area in the step 4) by the CODE algorithm to realize data correction through a BCH algorithm if 1 or 2 or 3 or 4-bit bit flipping is in the presence. The error correction method has the advantages that a backup power supply can be called to realize a purpose that a lamp of a bathroom can normally illuminate after outage.

Owner:NINGBO SANXING MEDICAL & ELECTRIC CO LTD

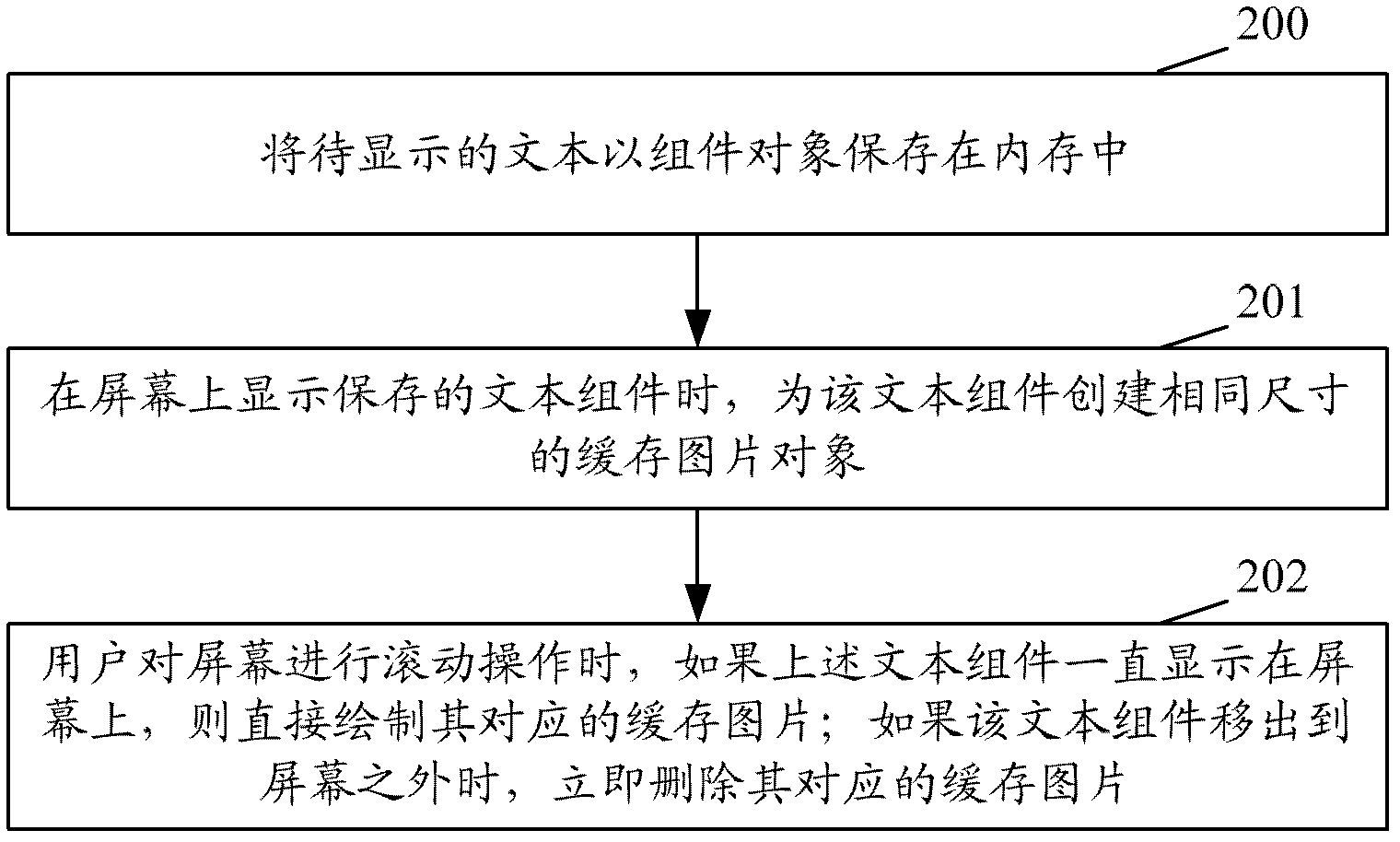

Method and terminal for achieving displaying cache

ActiveCN102981960AReduce areaSmall footprintMemory adressing/allocation/relocationSpecial data processing applicationsComputer graphics (images)Computer terminal

The invention discloses a method and a terminal for achieving displaying cache. The method for achieving displaying cache includes storing a to-be-displayed text inside an internal storage as a component object, and creating a caching picture object which is of the same side with the text component for the text component when the stored text component is displayed on a screen. As is seen from the method of screen caching, a caching picture just need to be created in an area with characters, and thus the internal storage occupied by a non-character area is saved. Therefore, the size and the occupied internal storage of the caching picture are decreased. Through the method for achieving displaying cache, on the premise that the repaid display effect is not affected, running cache is saved for a program, and cache requirements of product features are met.

Owner:TENCENT TECH (SHENZHEN) CO LTD

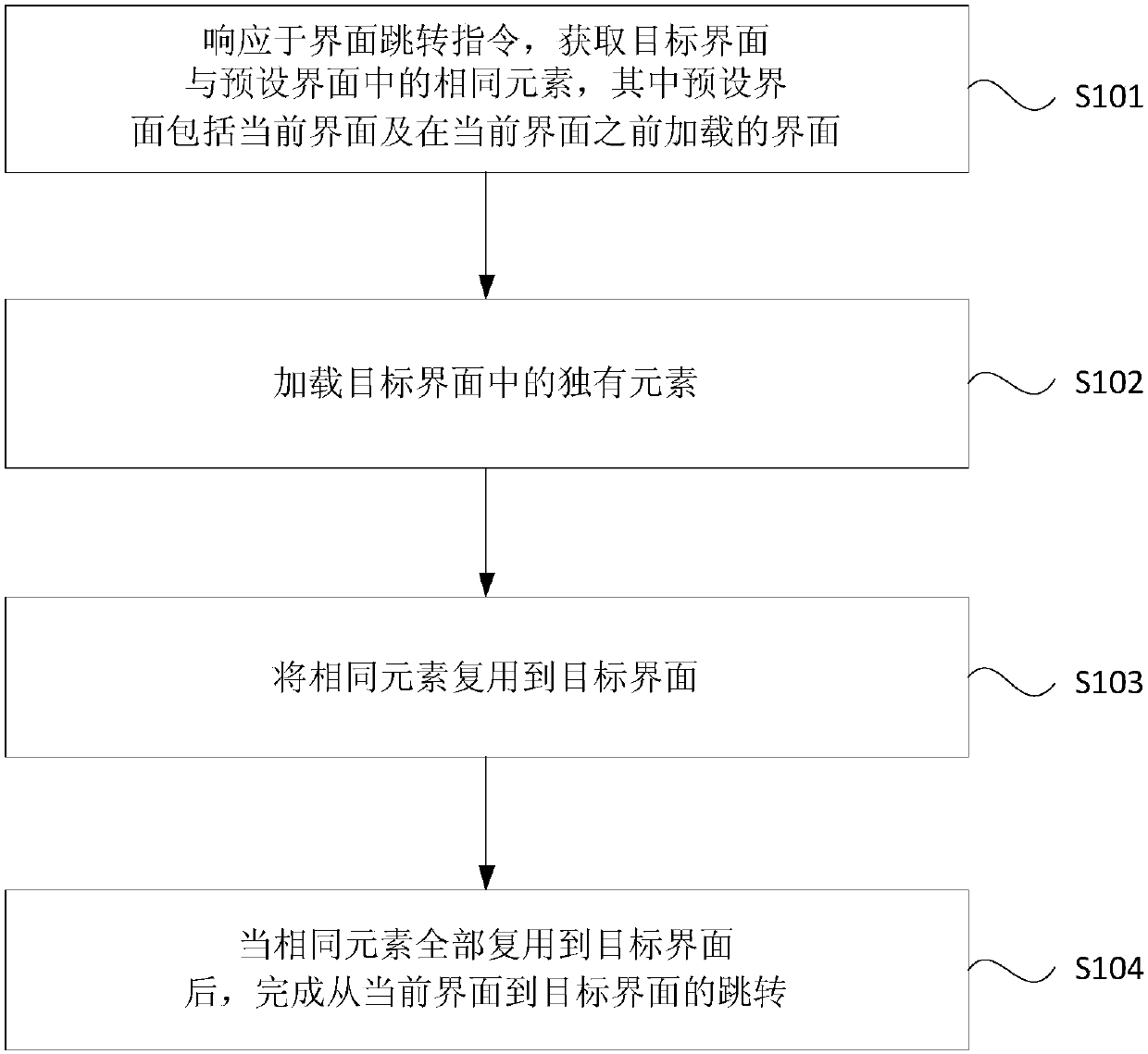

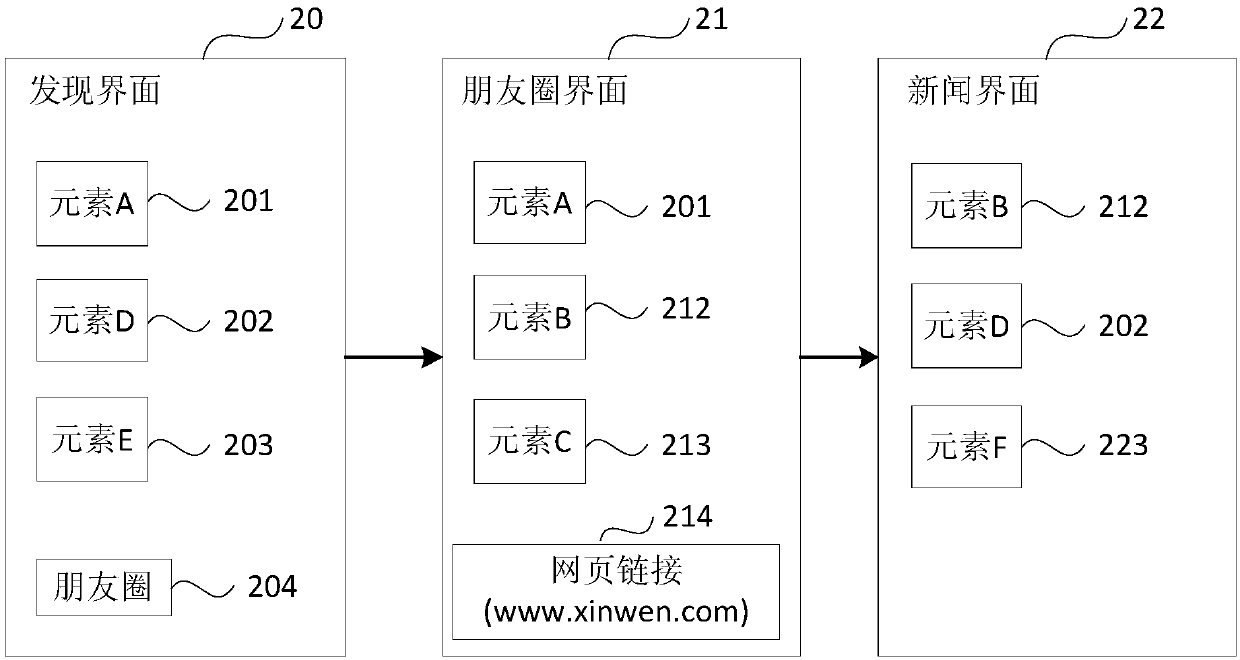

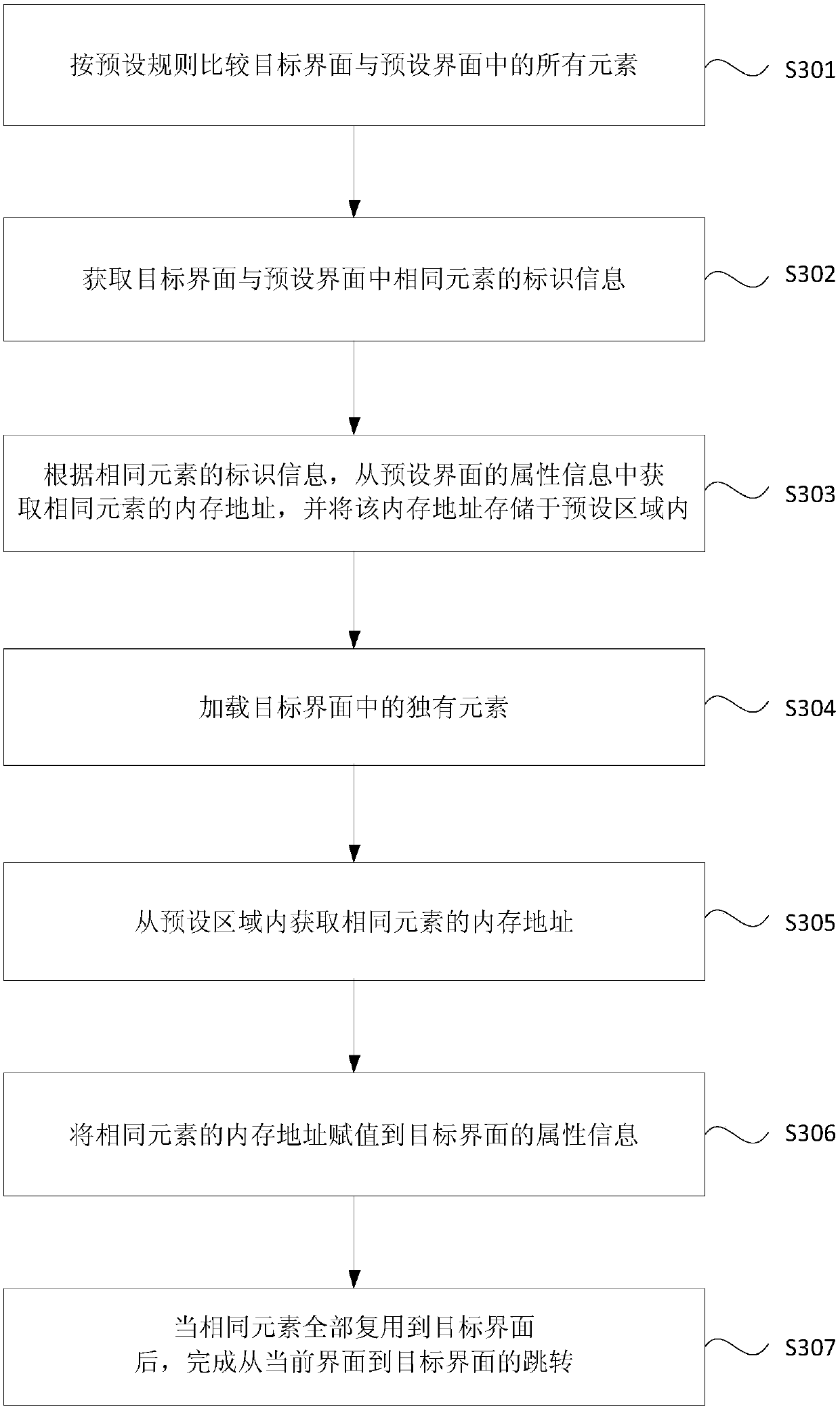

Interface skip method and device, terminal and storage medium

InactiveCN108037969AImprove loading timeSave running memoryExecution for user interfacesInput/output processes for data processingUnique elementComputer science

Owner:SHENZHEN LEXIN SOFTWARE TECH CO LTD

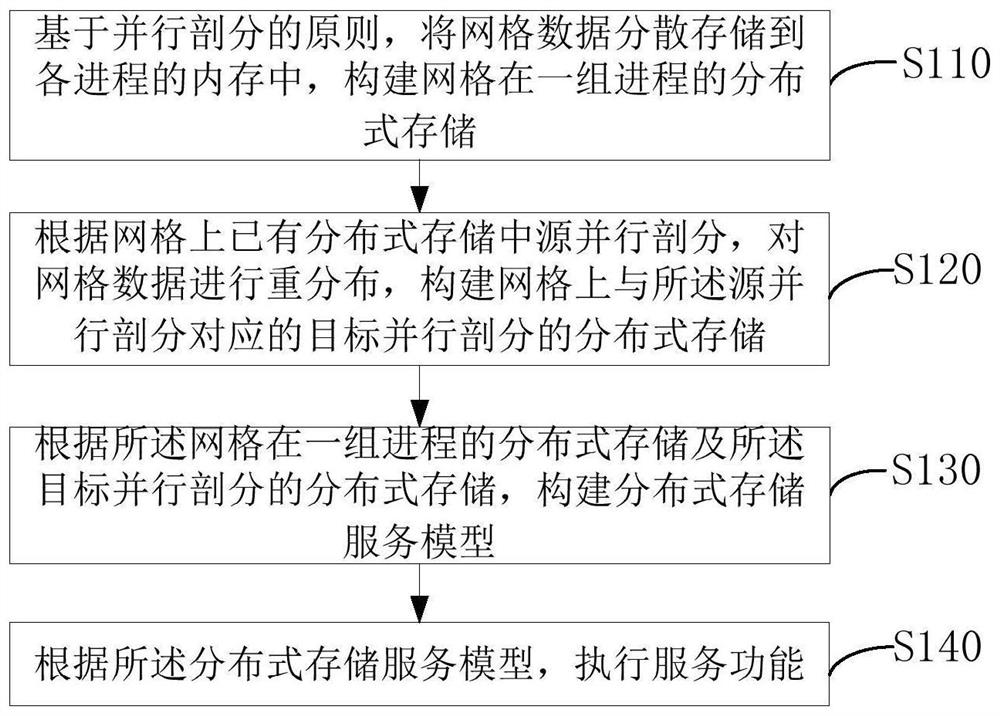

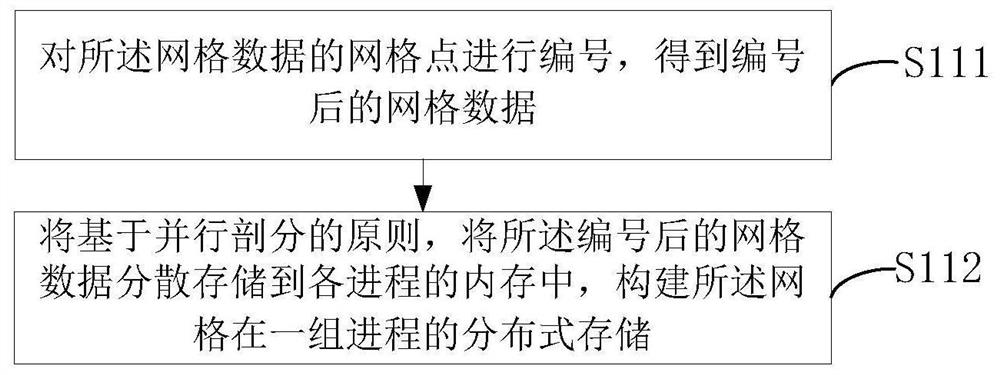

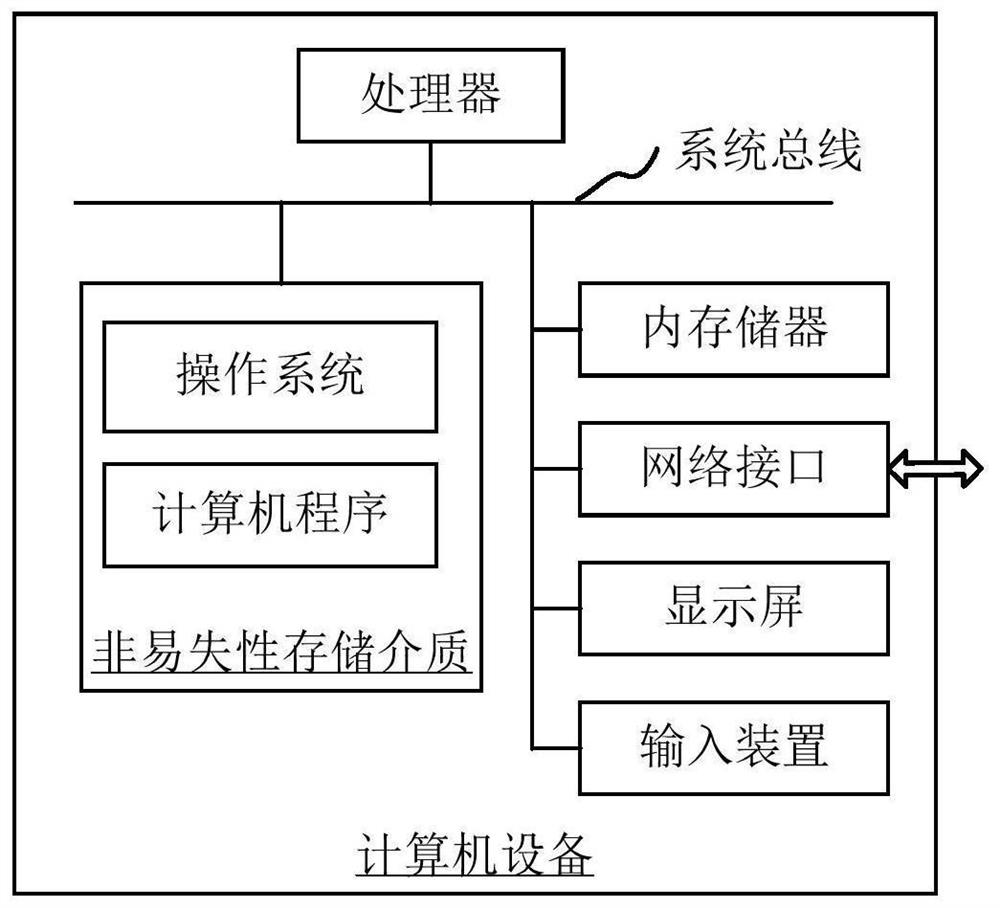

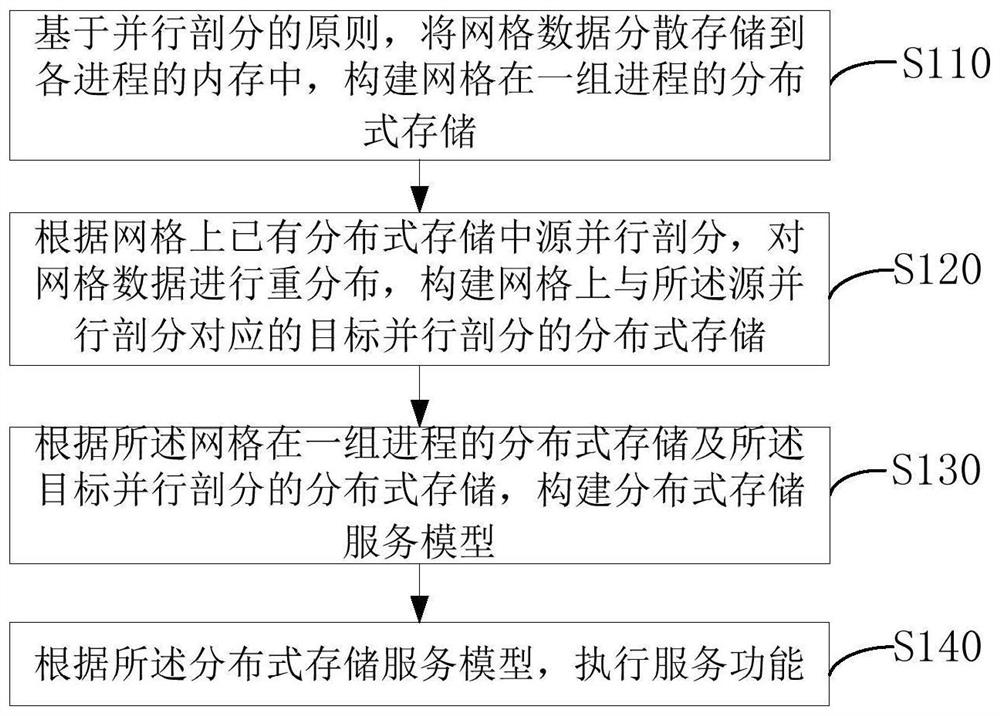

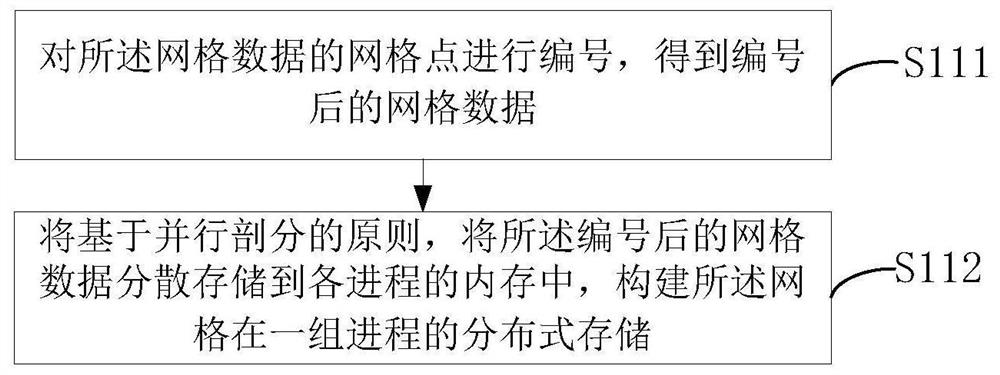

Grid data distributed storage service system, method, device, equipment and medium

ActiveCN113157806ASave running memoryImprove computing powerResource allocationDatabase distribution/replicationService systemMesh grid

The invention provides a grid data distributed storage service method, device and equipment and a medium, and the method comprises the steps: based on a parallel subdivision principle, storing grid data in a memory of each process in a dispersed manner, and constructing distributed storage of a grid in a group of processes; according to the source parallel subdivision in the existing distributed storage on the grid, redistributing the grid data, and constructing the distributed storage of the target parallel subdivision corresponding to the source parallel subdivision on the grid; constructing a distributed storage service model according to the distributed storage of the grid in a group of processes and the distributed storage of the target parallel subdivision; according to the distributed storage service model, executing a service function; the operation memory of the grid data in one process can be effectively reduced, the computing processing capacity of a computer is improved, and the performance bottleneck of storing large-scale grids in development and application of numerical programs such as a coupling mode is solved.

Owner:TSINGHUA UNIV

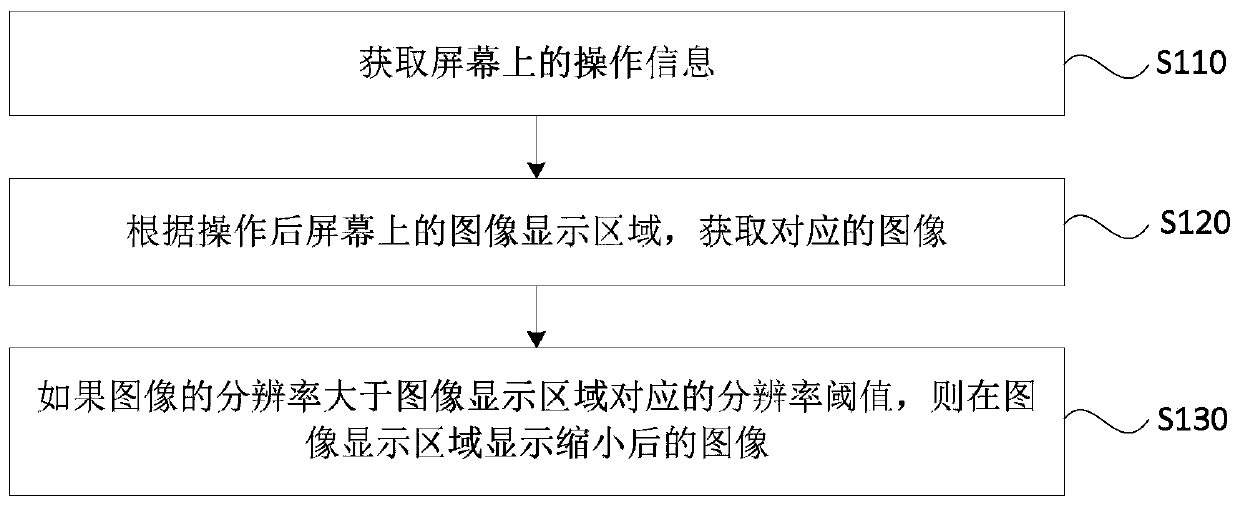

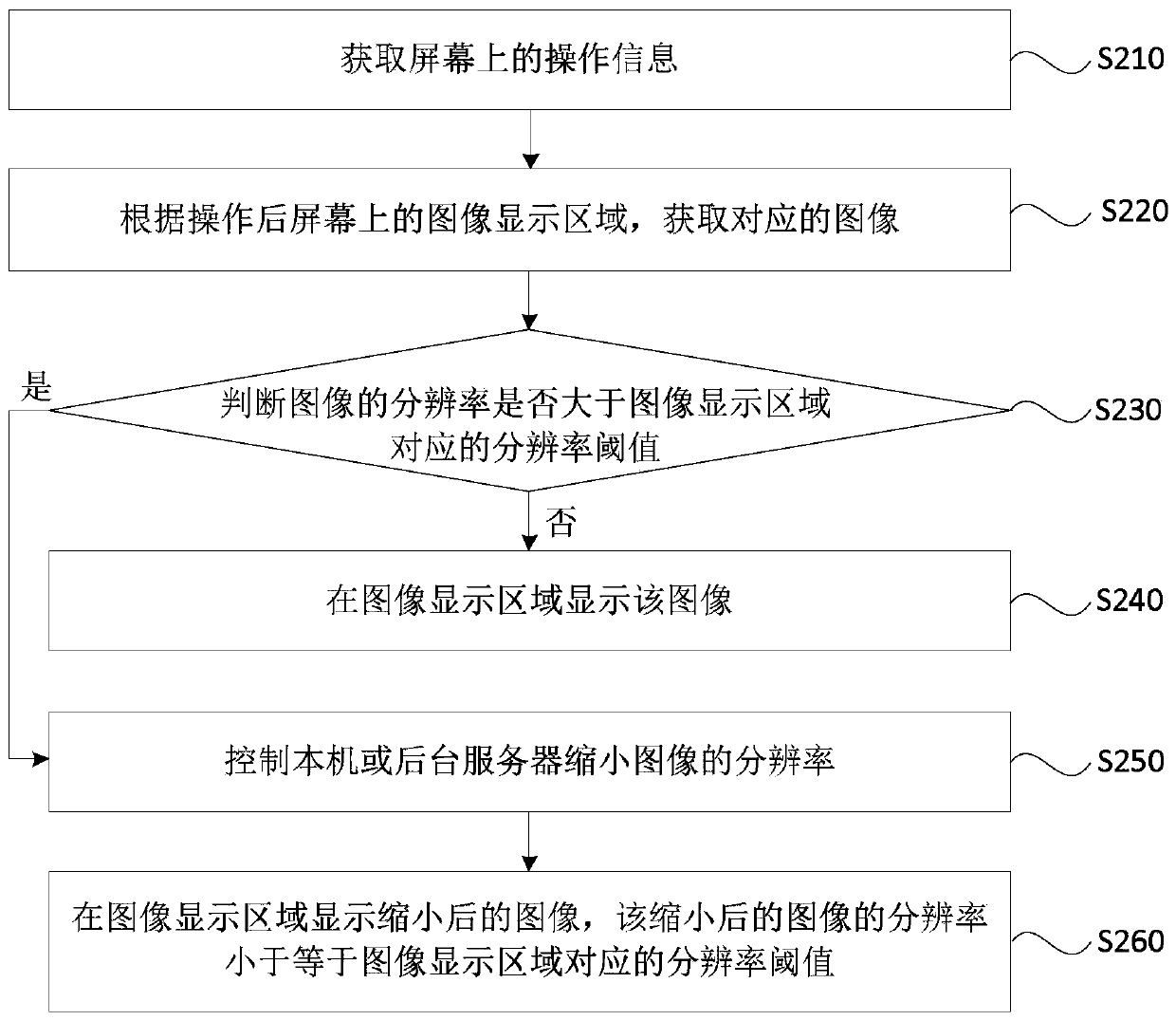

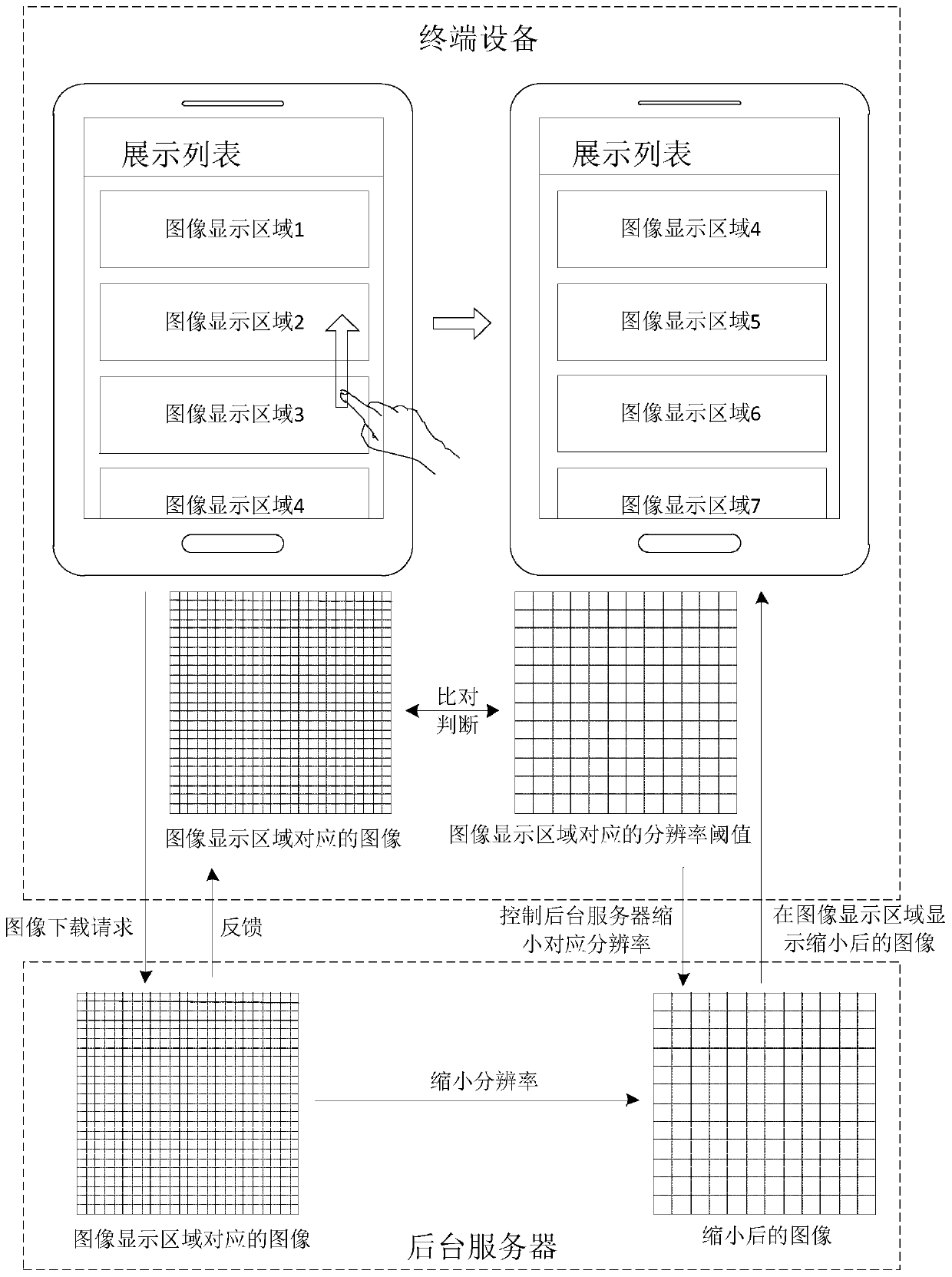

Image display method, device and equipment and storage medium

InactiveCN111381748AGuaranteed uptimeSave running memoryGeometric image transformationInput/output processes for data processingResolution thresholdComputer graphics (images)

The invention discloses an image display method, device and equipment and a storage medium. The method comprises: obtaining operation information on a screen; obtaining a corresponding image accordingto the image display area on the screen after operation; and if the resolution of the image is greater than the resolution threshold corresponding to the image display area, displaying the reduced image in the image display area, the resolution of the reduced image being less than or equal to the resolution threshold corresponding to the image display area. According to the technical scheme provided by the embodiment of the invention, the resolution threshold corresponding to the image display area is determined, the image with the resolution greater than the resolution threshold is reduced,and then the reduced image is displayed in the image display area, so the resolution of the reduced image meets the requirement of the resolution threshold value, pixel information contained in the displayed image in the operation process is reduced, the operation memory occupied by image display is reduced, and the image display efficiency and the operation performance of the application programare improved.

Owner:GUANGZHOU BAIGUOYUAN INFORMATION TECH CO LTD

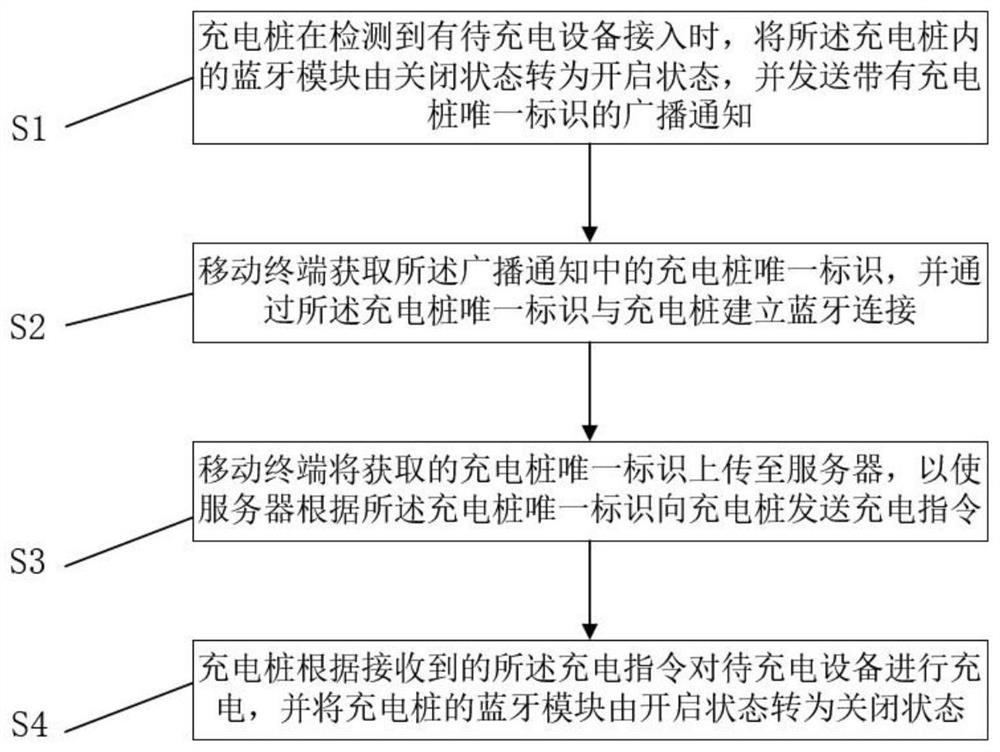

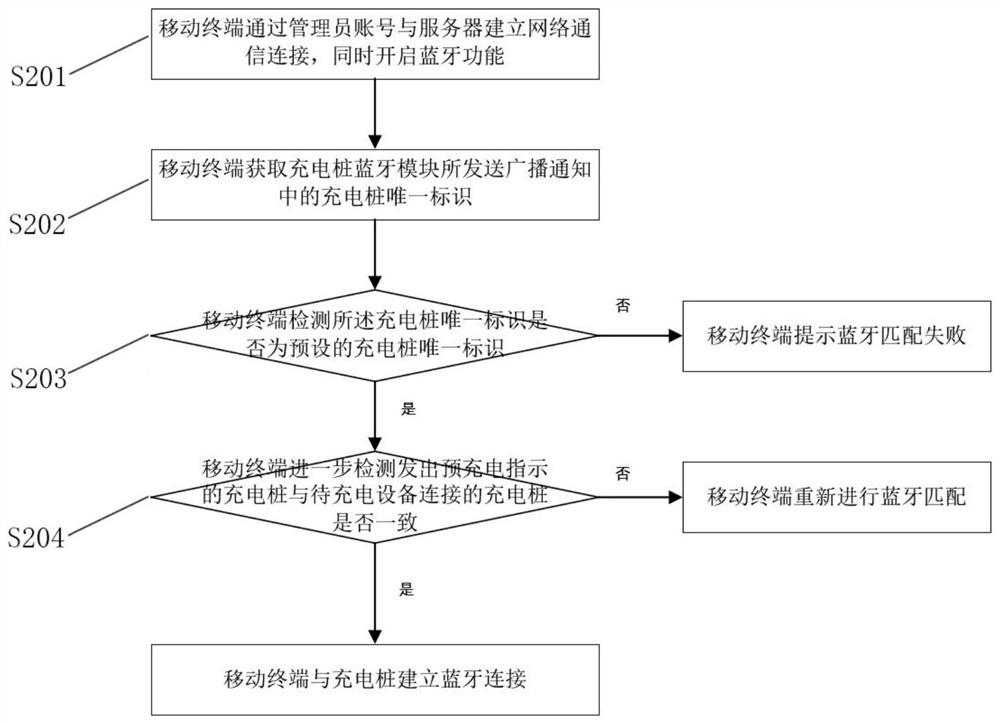

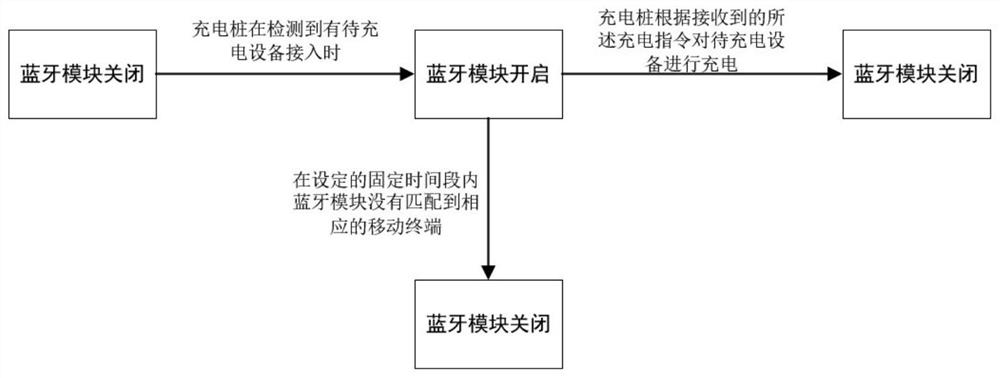

Bluetooth connection based charging method and system and storage medium

ActiveCN113352924ASave running memoryEasy to operateCharging stationsConnection managementEmbedded systemTelecommunications

The invention belongs to the technical field of charging, and particularly relates to a Bluetooth connection-based charging method and system and a storage medium. The method comprises the steps that a Bluetooth module in a charging pile is converted from a closed state to an open state when the charging pile detects the access of a to-be-charged device, and a broadcast notification with a unique identifier of the charging pile is transmitted; a mobile terminal obtains the unique identifier of the charging pile in the broadcast notification, and establishes a Bluetooth connection with the charging pile through the unique identifier of the charging pile; the mobile terminal uploads the obtained unique identifier of the charging pile to a server, so that the server sends a charging instruction to the charging pile according to the unique identifier of the charging pile; and a charging pile charges to-be-charged equipment according to the received charging instruction, and converts a Bluetooth module of the charging pile into a closed state from an open state. The mobile terminal identifies the charging pile in a Bluetooth communication mode, the occupied running memory of the mobile terminal is smaller, and operation is smooth; and the Bluetooth module is built-in and is not easy to damage.

Owner:ZHENGZHOU YIJIAANHAO SOFTWARE TECH CO LTD

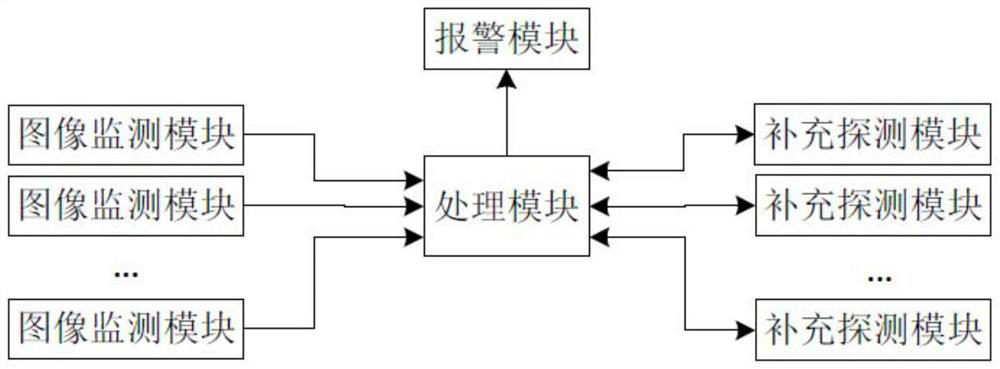

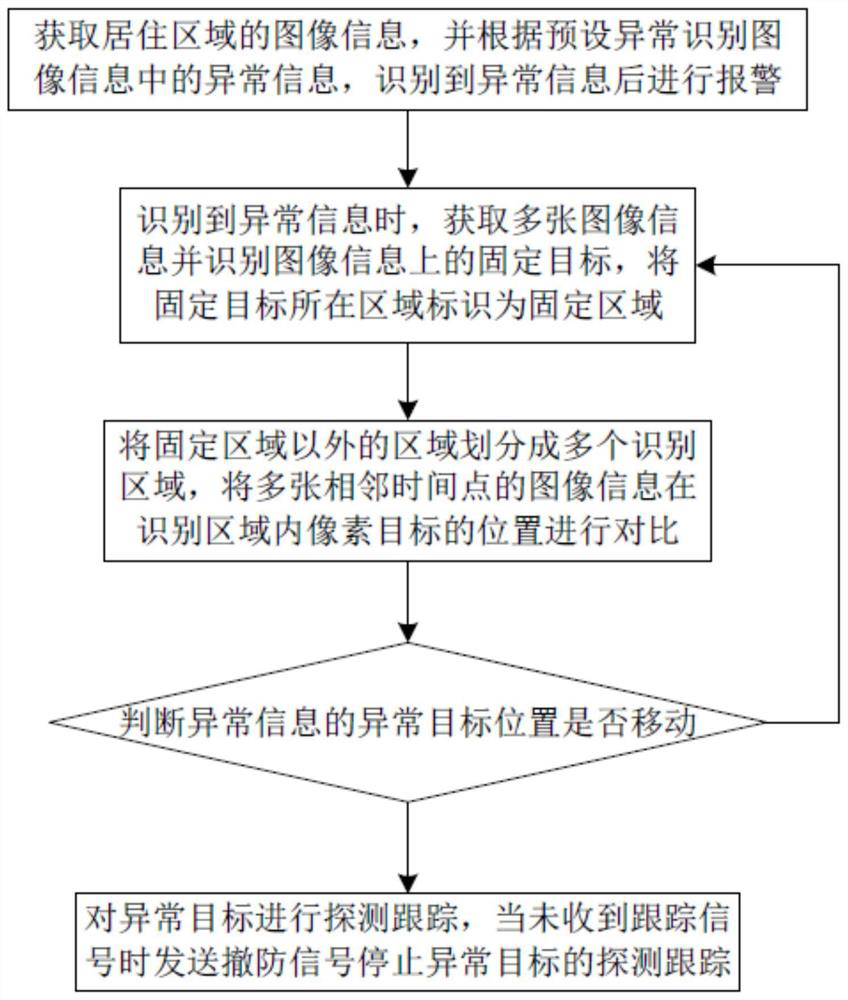

Defense organizing system and method for periphery of living area

ActiveCN113223261ATake advantage ofImprove accuracyTelevision system detailsColor television detailsEngineeringComputer vision

The invention relates to the field of security fence equipment, in particular to a defense organizing system and method for the periphery of a living area, the system comprises a plurality of image monitoring modules, a processing module, an alarm module and a plurality of supplementary detection modules, the method comprises the following steps: S1, identifying abnormal information in image information of the living area and giving an alarm, and S2, acquiring multiple pieces of image information and comparing to judge whether an abnormal target of the abnormal information moves or not; S3, when the abnormal target moves, detecting and tracking the abnormal target, and when a tracking signal is not received, sending a defense withdrawing signal to stop the detection and tracking of the abnormal target. Detection and tracking are carried out only when the system is abnormal, the running memory of the system is saved, and the energy consumption of the system is reduced.

Owner:重庆天智慧启科技有限公司

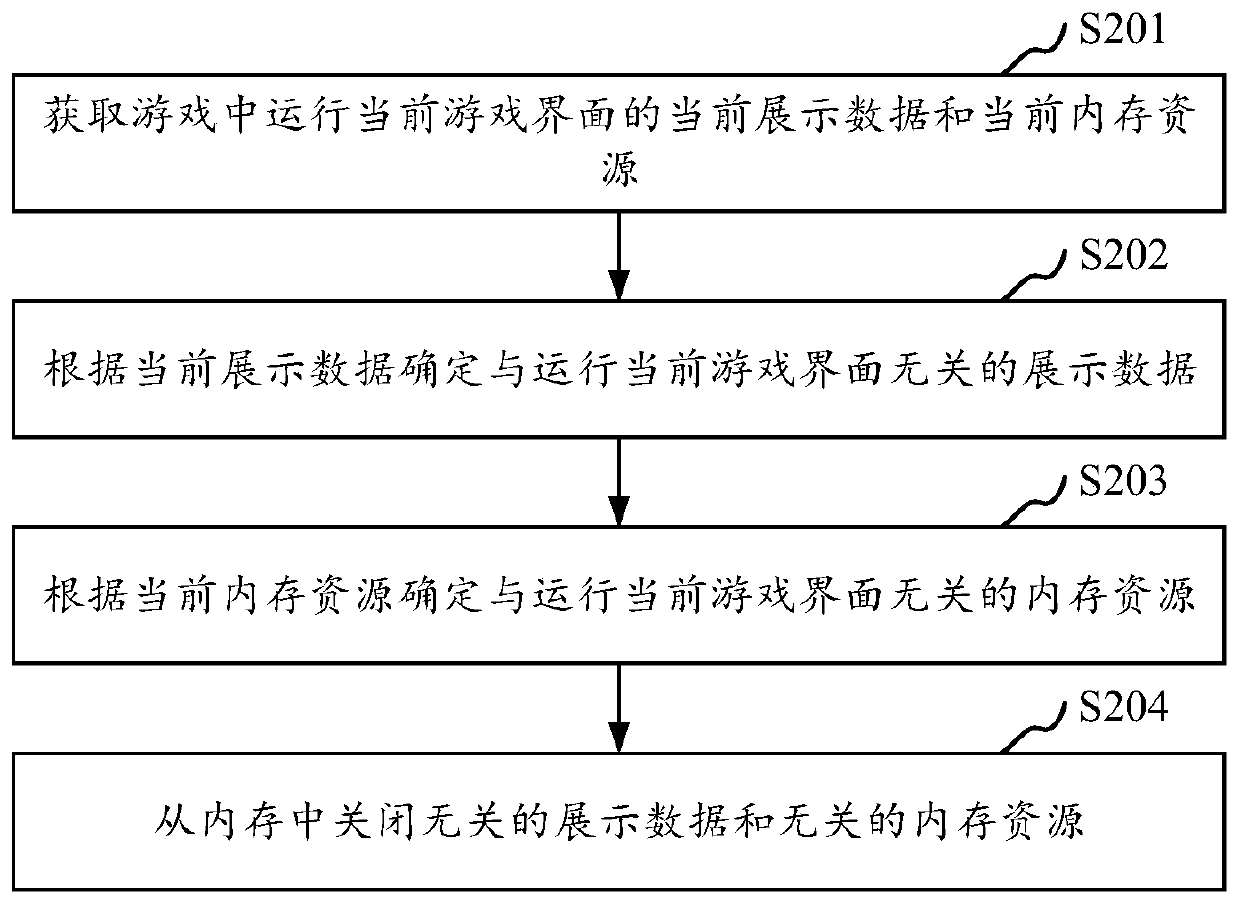

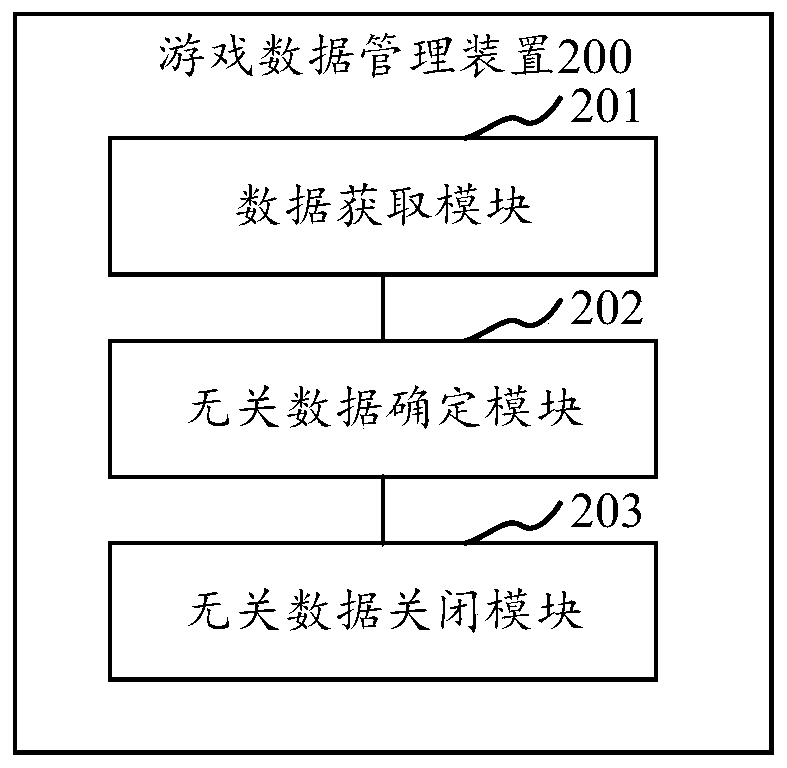

Game data management method and device, computing device and storage medium

The invention relates to a game data management method and device, a computing device and a storage medium. The method includes the steps of obtaining the current display data and current memory resources of a current running game interface in a game, determining display data unrelated to the current running game interface according to the current display data, determining memory resources unrelated to the current running game interface according to the current memory resources, and closing the unrelated display data and unrelated memory resources in memory. Through the display data and memoryresources corresponding to the current game interface, the data related to the current running game interface and the data unrelated to the current running game interface are determined, the unrelated data is closed, the running memory is reduced, and the running speed is increased.

Owner:SHENZHEN TCL NEW-TECH CO LTD

Method and system for displaying characters

ActiveCN102169423BIncrease flexibilitySave running memoryCathode-ray tube indicatorsDigital output to display deviceAlgorithmComputer graphics (images)

The utility model relates to a method for displaying characters, which belongs to the technical field of computers, and comprises the steps as follows: lattice information of characters to be displayed is obtained according to a typeface file used for keeping lattice information of characters in a program and a whole character table keeping the position information of the characters in the typeface file; and the characters are displayed according to the lattice information of the characters to be displayed. Besides, the invention also relates to a system for displaying characters according to the method. In the method and the system, a program developer can use self-defined typefaces through using the built-in typeface file, and the flexibility on the aspect of using different styles of typefaces is improved. Moreover, compared with the characters displayed through pictures, displaying the characters by using the lattice information of the characters can greatly reduce a running memory, and can display the unknown typefaces in advance in real time according to the typeface file.

Owner:TENCENT TECH (BEIJING) CO LTD

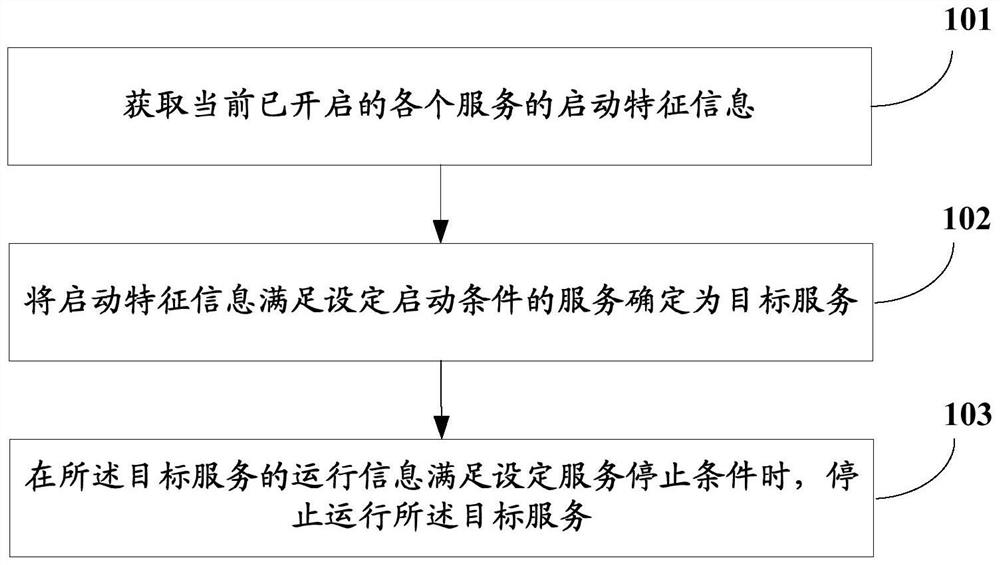

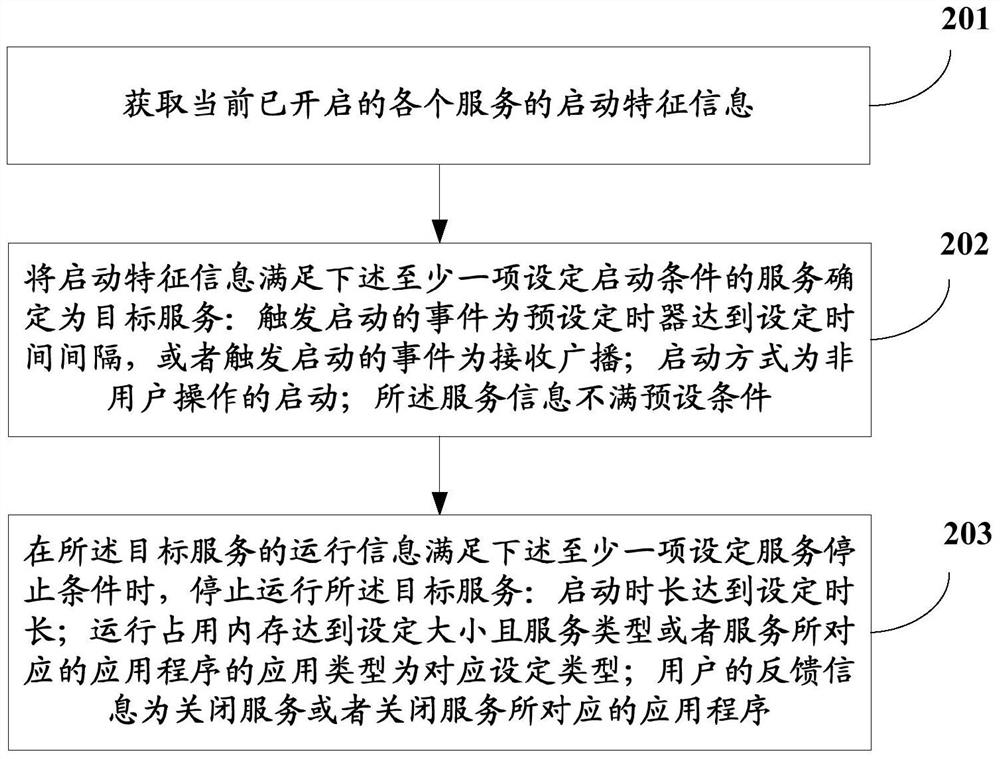

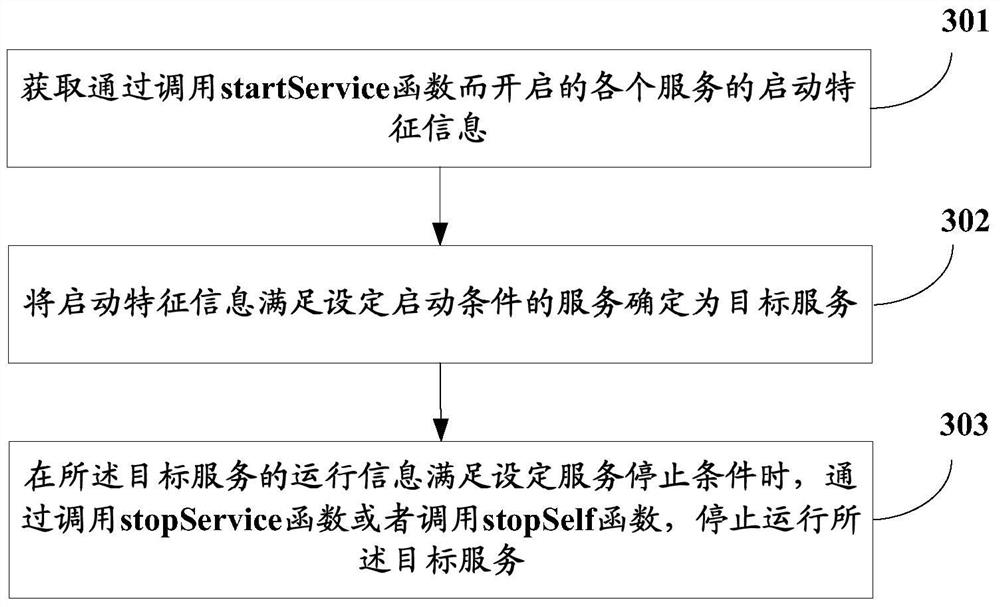

Application service control method, device, storage medium and mobile terminal

ActiveCN107885588BSave running memorySave powerProgram initiation/switchingDigital data processing detailsService controlEngineering

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

A device and method for detecting the cross-sectional bending profile of a planar bending sheet metal part

ActiveCN108592819BHigh sensitivityHigh measurement accuracyUsing optical meansMicrocomputerPoint cloud

Provided is a device for detecting the curved contour of a section of the planar bent sheet metal part. The device comprises a mechanical device and a control device. The control device comprises a control box, a PLC, a single-chip microcomputer and a computer. The mechanical device comprises a frame, an X-direction translation module, a Y-direction translation module and a linear array CCD camera. A detecting method adopting the detecting device mainly comprises the steps the contour position information collected by the linear array CCD camera and Y-module coder data of the mechanical deviceare combined and serve as a Y coordinate value of a metal plate contour two-dimensional diagram after data processing, position data fed back by a X-module servo motor coder in the mechanical deviceis adopted as an X coordinate value of the metal plate contour two-dimensional diagram, metal plate contour circulating scanning and contour point data collection are completed through control of a driving program, and a two-dimensional point cloud file related to the curved contour of the sheet metal part is obtained after upper computer data processing is carried out. The device is automatic, efficient and cheap and can extract contour data fast and conveniently.

Owner:YANSHAN UNIV

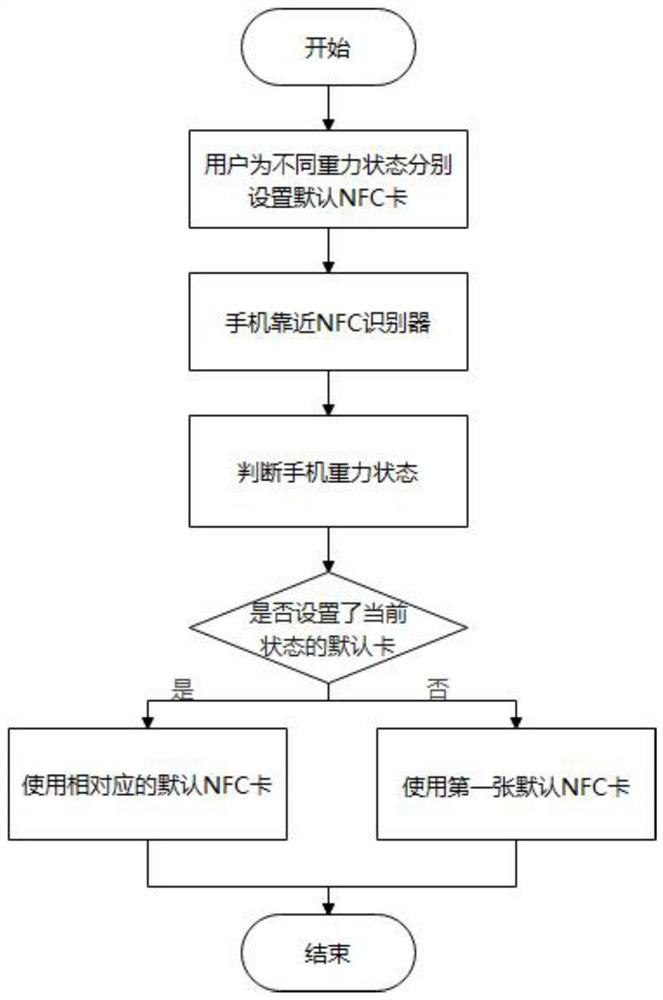

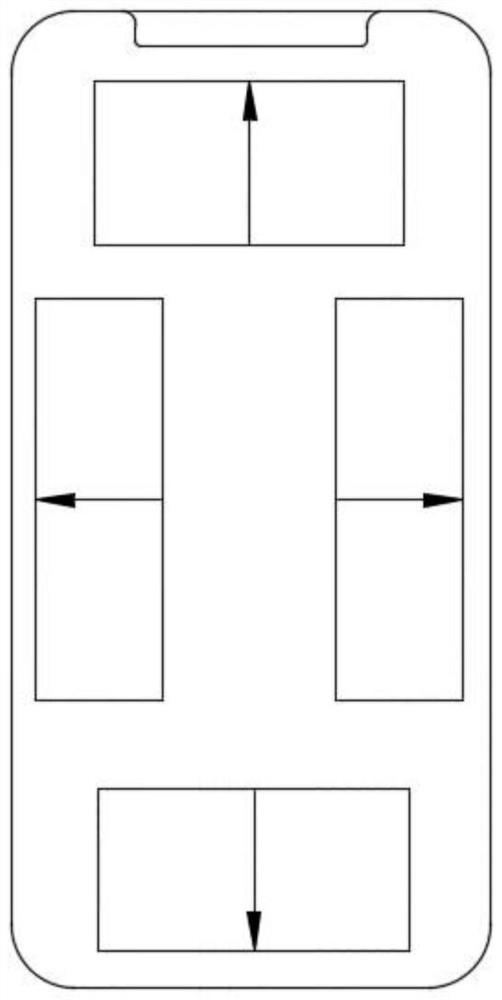

Method for controlling default NFC card

PendingCN114662511AGuaranteed accuracyReduced impact during normal useBootstrappingRecord carriers used with machinesPersonal computerMobile device

The invention discloses a method for controlling a default NFC (Near Field Communication) card, which comprises a mobile device, the mobile device is provided with a gravity sensor, and the mobile device has and starts an NFC function, and comprises the following steps: default setting: starting an APP (Application) supporting an NFC simulation card, and setting a default card in different gravity directions; the reading setting is as follows: the mobile equipment is close to equipment with an NFC (Near Field Communication) reader; state judgment: the APP receives the NFC reading request and obtains the current position and gravity state of the mobile equipment; and judging a default card: reading the set default card according to the current position and the gravity state of the mobile equipment. The invention provides a method for controlling a default NFC (Near Field Communication) card, which is characterized in that the NFC card is preset according to the use frequency and the size required by use of each NPC (Near Personal Computer) card, and the following specific operations are performed: a preset APP (Application) is entered, and four areas are sensed by a gravity sensor: the area is vertically downward and reverse when a mobile phone is in a use state, and the area is horizontally laterally placed and directional when a power supply side key is on the upper side.

Owner:润芯微科技(江苏)有限公司

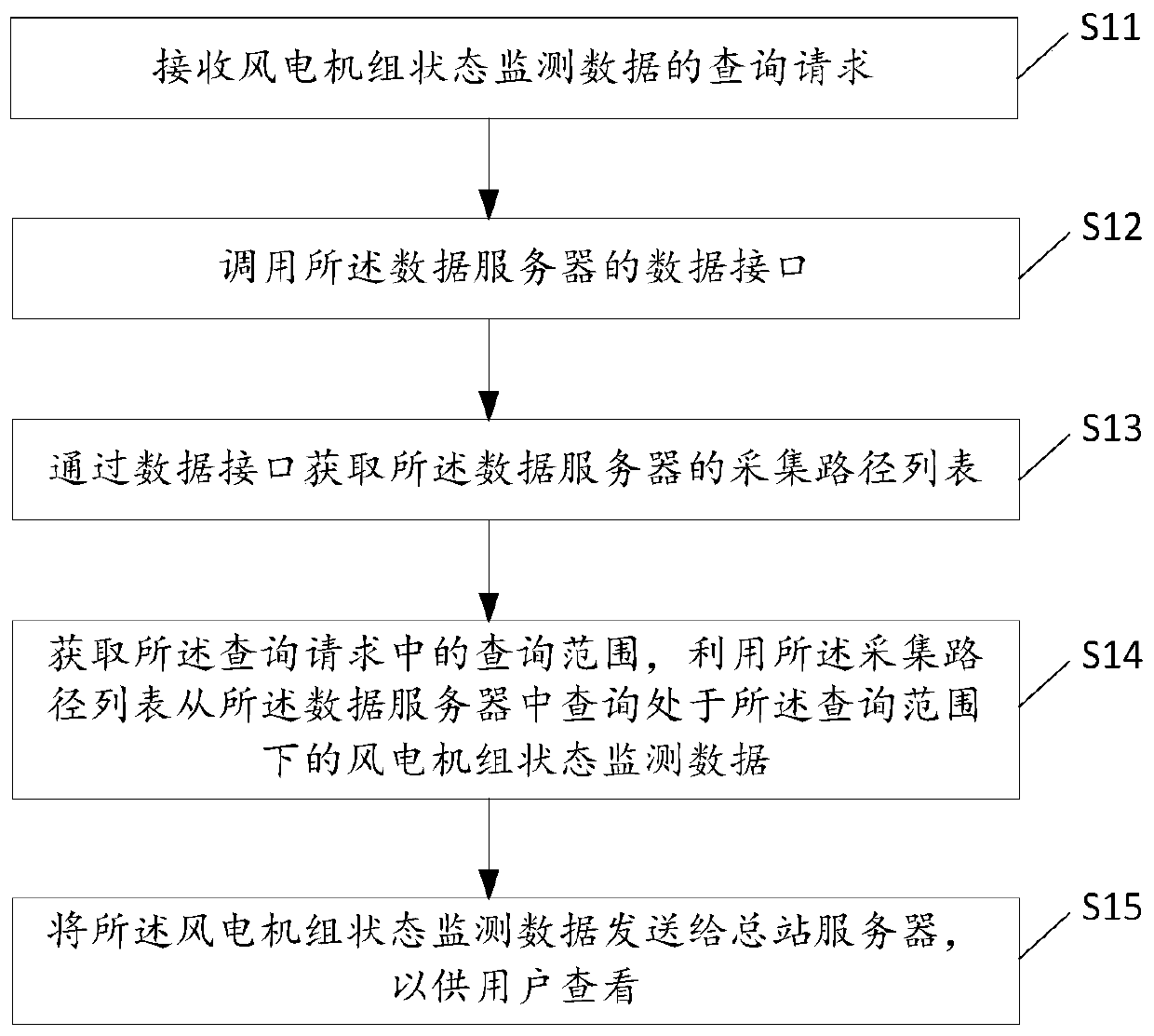

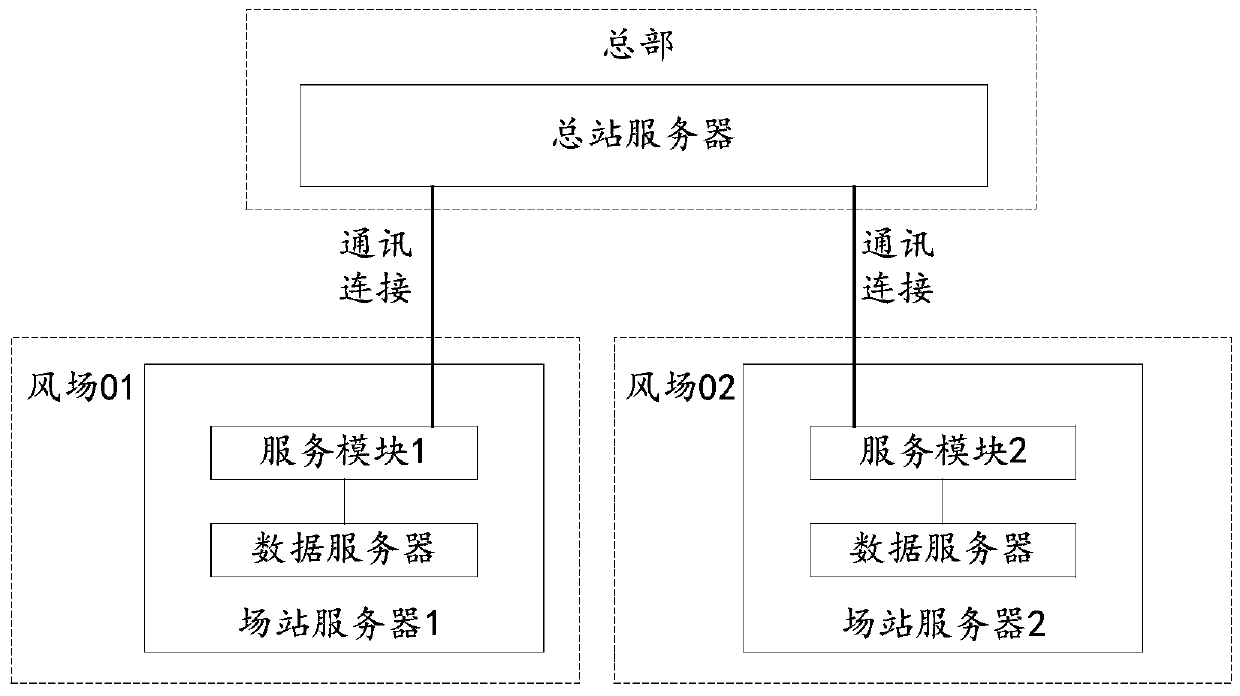

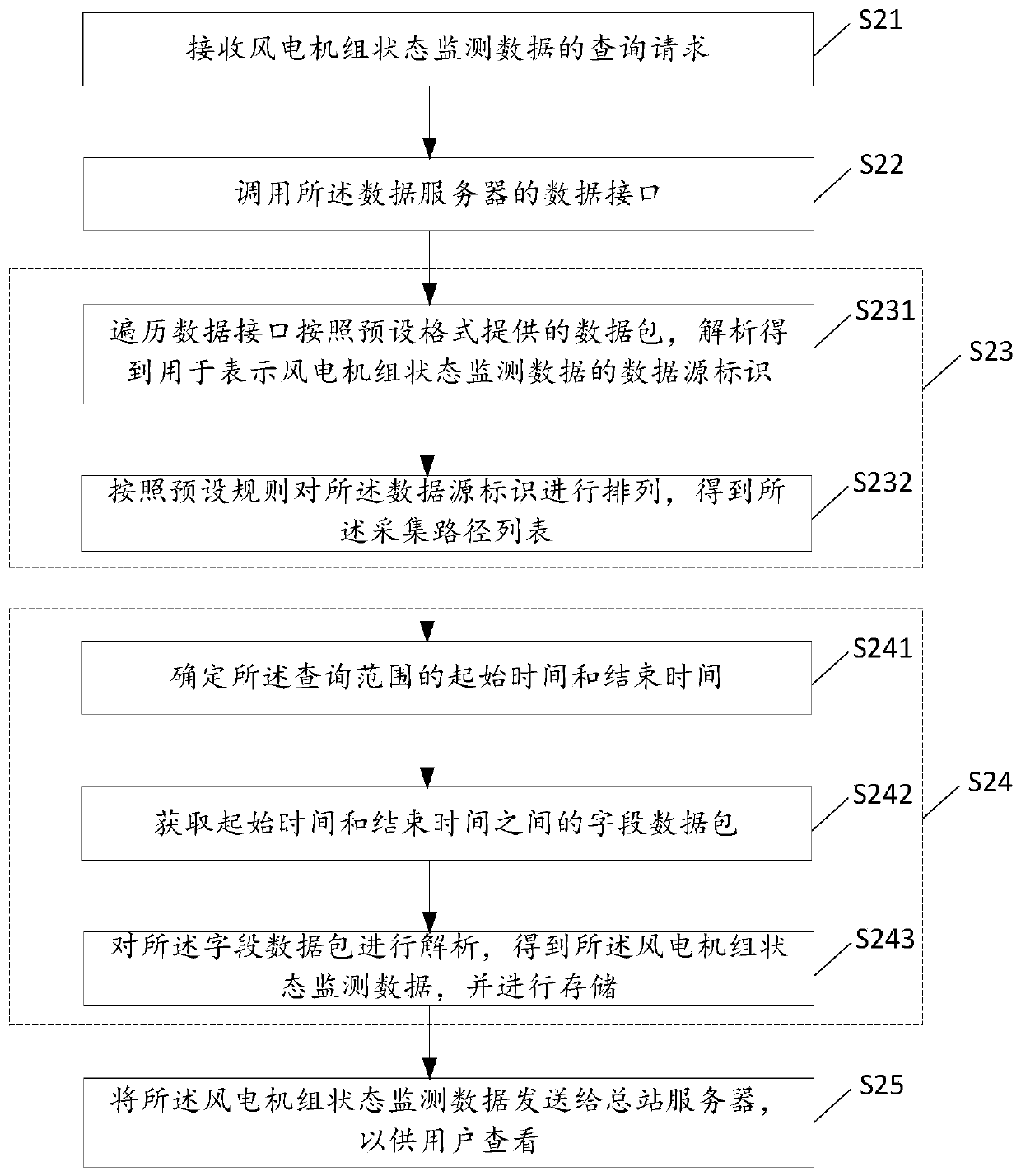

Wind turbine generator set state monitoring data acquisition method and query method and electronic equipment

PendingCN111522642AImprove unityEasy to viewProgram initiation/switchingDatabase management systemsMaster stationData acquisition

The invention relates to the technical field of wind turbine generator set state monitoring, in particular to a wind turbine generator set state monitoring data acquisition method and query method andelectronic equipment. The acquisition method comprises the steps: receiving a query request of wind turbine generator set state monitoring data; calling a data interface of a data server; acquiring an acquisition path list of the data server through a data interface; obtaining a query range in the query request, and querying wind turbine generator set state monitoring data in the query range fromthe data server by utilizing the acquisition path list; and sending the wind turbine generator set state monitoring data to a master station server for a user to check. According to the acquisition method provided by the invention, the data interface of the data server is called, the wind turbine generator state set monitoring data in the query range is queried from the data server and sent to the master station server by utilizing the acquisition path list of the data server, and the master station server does not need to install software corresponding to each station server, so that the user can check the data conveniently.

Owner:GUANWEI MONITORING TECH WUXI CO LTD

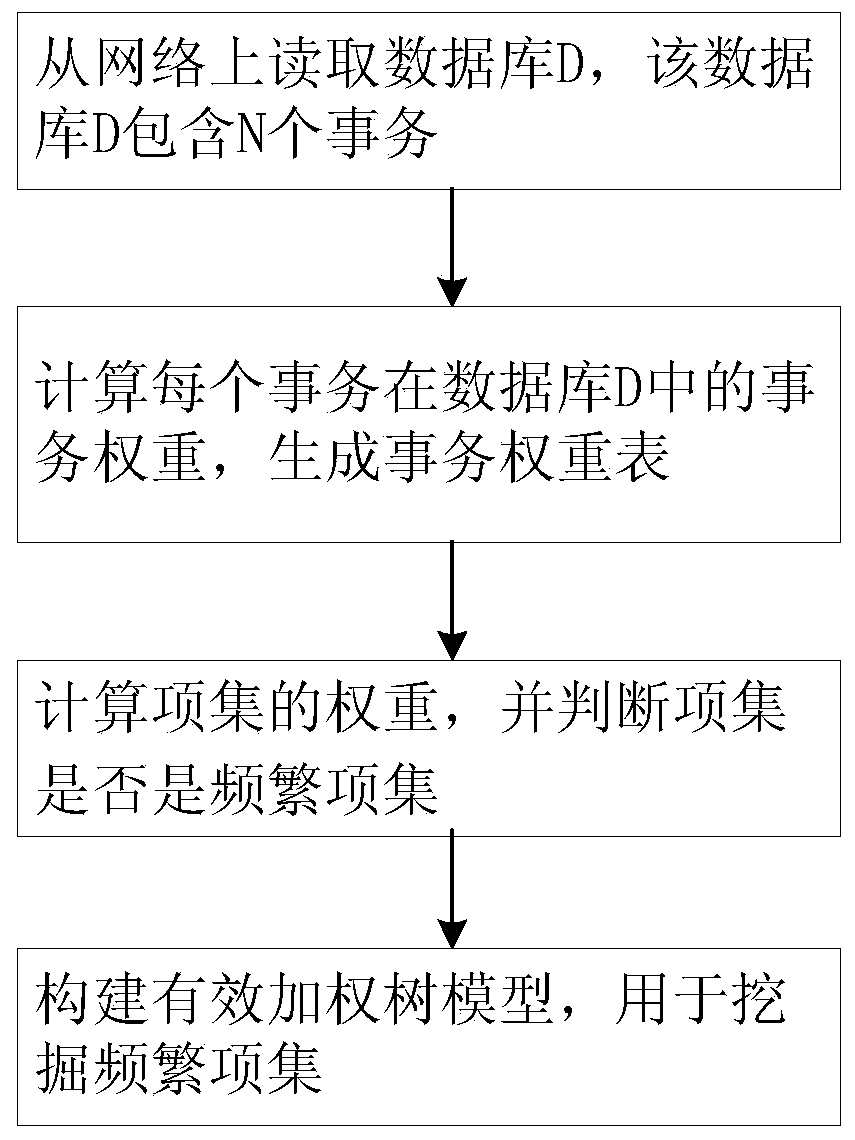

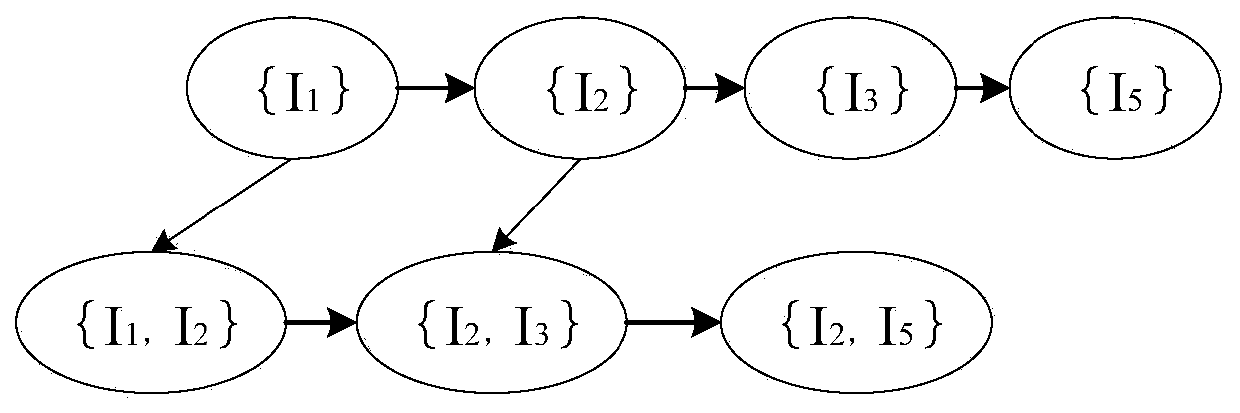

Method for mining frequent weighting item set based on effective weighting tree

ActiveCN110096629AQuick digEfficient miningOther databases queryingEnergy efficient computingData libraryBig data

The invention discloses a method for mining a frequent item set based on an effective weighted tree, comprising the following steps: S1, reading a database D from a network, the database D comprisingN transactions, each transaction comprising different items, the number of items and the weight w occupied by each item; S2, calculating a transaction weight tw of each transaction in the database D,and generating a transaction weight table; S3, calculating the weight W of the item set S, and presetting a threshold value minws, wherein if W is greater than or equal to minws, sthe item set S is afrequent item set; if W < minws, the item set S is a non-frequent item set; and S4, constructing an effective weighted tree model for mining the frequent item set. According to the method, weights aregiven to the item sets, weight calculation is carried out, so that an effective weighted tree model is constructed, the mining efficiency of the frequent item sets is improved, memory application isreduced, and the method is suitable for a database of big data.

Owner:CHONGQING UNIV

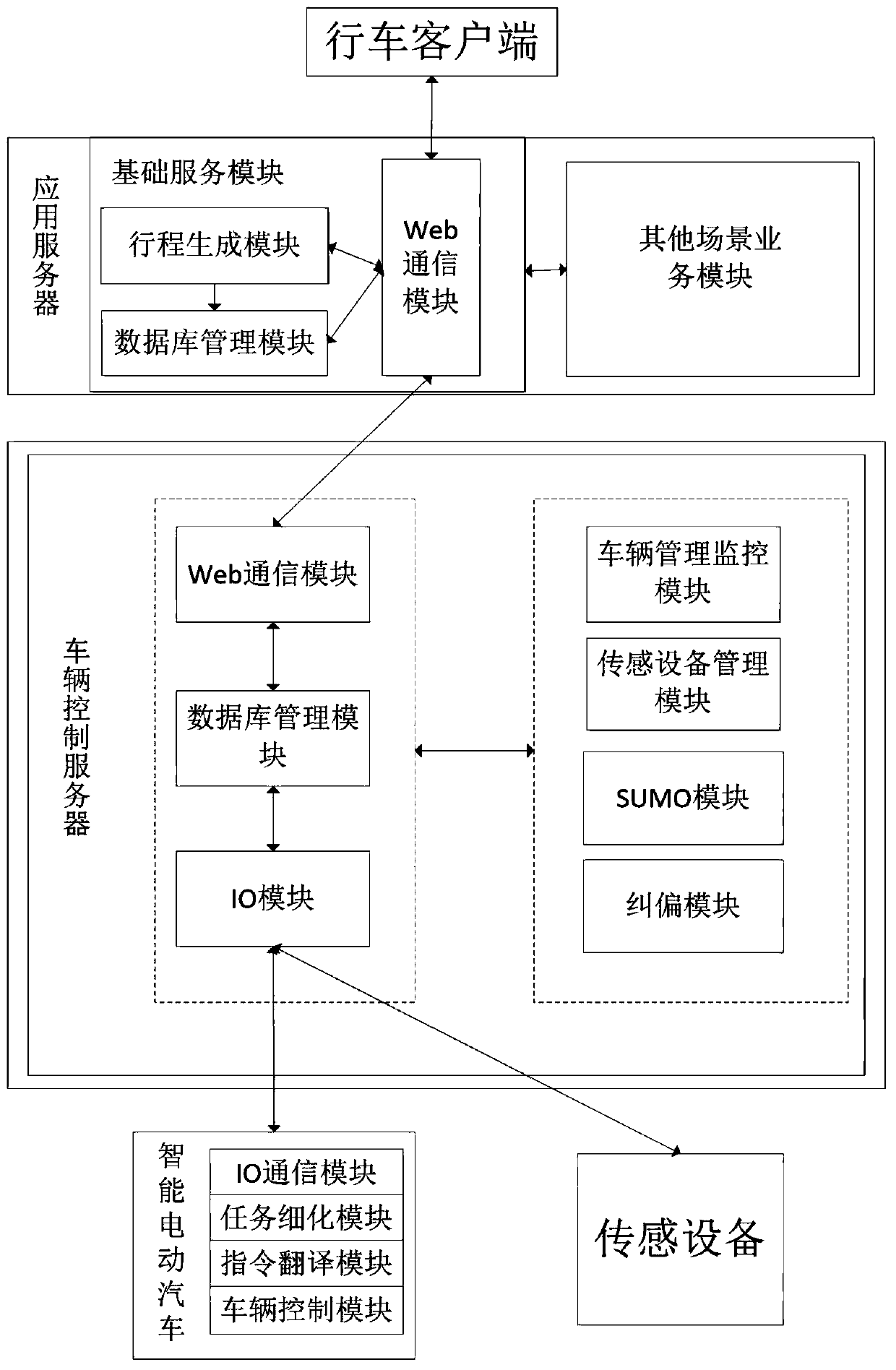

A cloud-controlled autonomous driving system based on sumo and unified timeline

ActiveCN107463172BSolve storage spaceSolve the lack of computing powerPosition/course control in two dimensionsTimestampApplication server

The invention discloses a cloud-controlled automatic driving system based on SUMO and a unified timeline, including a driving client, an application server, a vehicle control server, an intelligent electric vehicle and a sensing device; the automatic driving system uses the driving client to issue travel instructions , use the application server to parse and encapsulate the travel instructions, use the SUMO module in the vehicle control server for path planning and driving task division, and use the GPS and correction module to generate vehicle correction instructions; the vehicle uses the driving task instructions and vehicle correction instructions of the vehicle control server travel. In the system of the present invention, the application server, vehicle control server, and smart electric vehicle use a unified time axis, and the vehicle executes at the specified time according to the time stamp in the instruction. The invention realizes cloud-controlled vehicle automatic driving while avoiding network delay and instability problems. It uses SUMO and unified timeline to further simplify the system and improve system reliability.

Owner:ZHEJIANG UNIV

Grid data distributed storage service system, method, device, equipment and medium

ActiveCN113157806BRealize data transmissionSave running memoryResource allocationDatabase distribution/replicationParallel computingEngineering

The present invention provides a grid data distributed storage service method, device, equipment and medium. The method includes: based on the principle of parallel subdivision, the grid data is dispersedly stored in the memory of each process, and the grid is constructed in a group Distributed storage of processes; according to the source parallel subdivision of the existing distributed storage on the grid, redistribute the grid data, and construct the distributed storage of the target parallel subdivision corresponding to the source parallel subdivision on the grid ; According to the distributed storage of the grid in a group of processes and the distributed storage of the target parallel subdivision, construct a distributed storage service model; according to the distributed storage service model, perform service functions; can effectively reduce network The running memory of grid data in a process improves the computing and processing capabilities of computers, and solves the performance bottleneck of storing large-scale grids in the development and application of numerical programs such as coupled models.

Owner:TSINGHUA UNIV

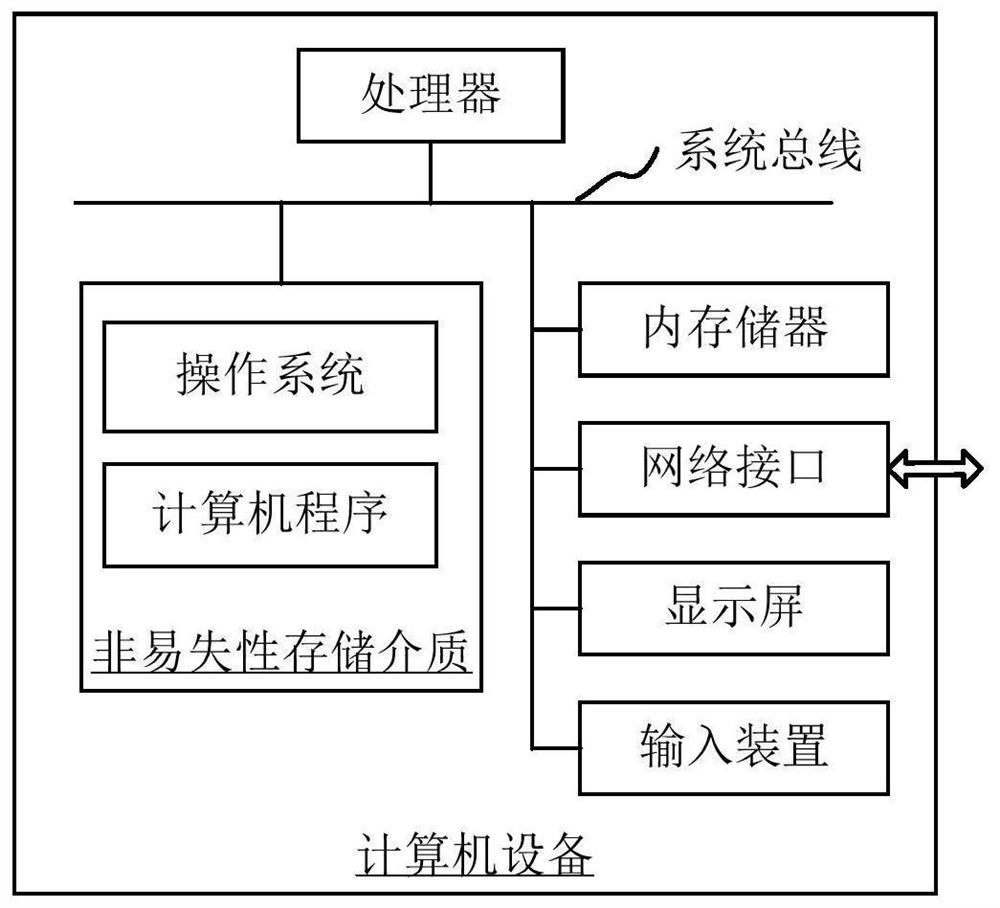

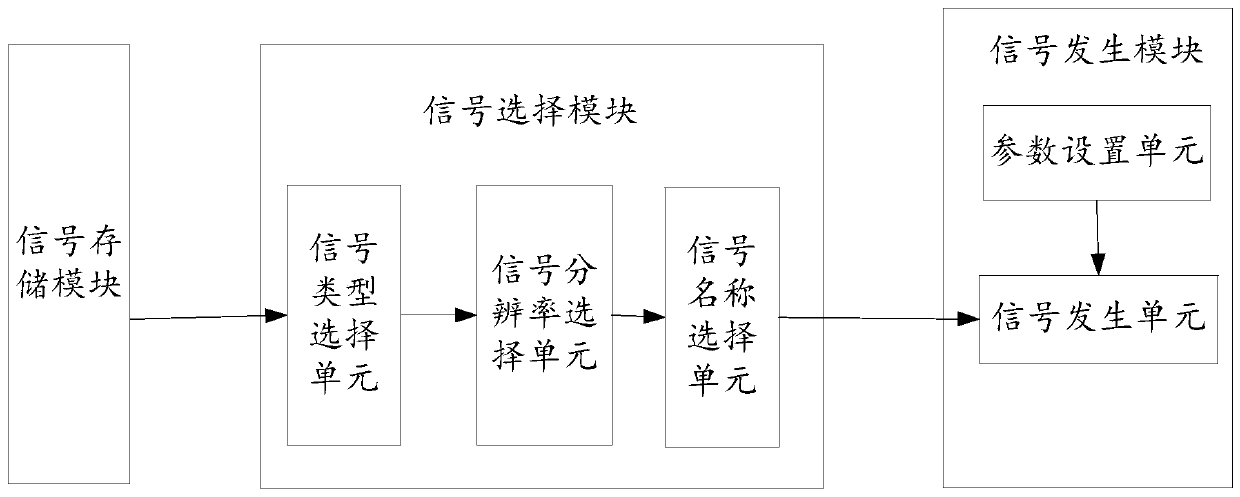

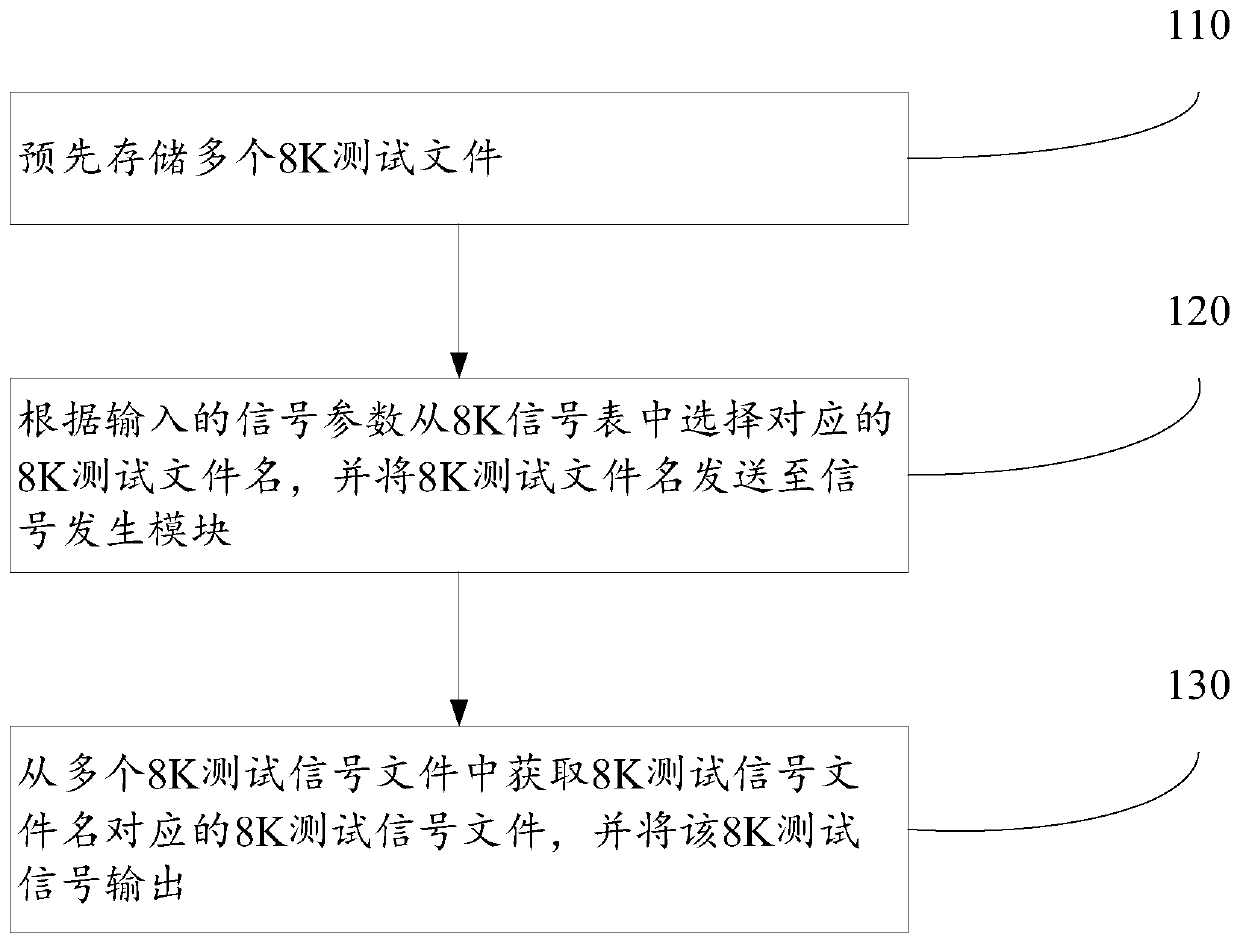

8K test signal generation device and method, storage medium and equipment

InactiveCN110944168AReduced running memory requirementsSave running memoryTelevision systemsComputer hardwareEngineering

The invention relates to an 8K test signal generation device. The 8K test signal generation device comprises a signal storage module, a signal selection module and a signal generation module; the signal storage module is used for storing a plurality of 8K test signal files in advance; the signal selection module is used for selecting a corresponding 8K test signal file name from an 8K signal tableaccording to input signal parameters and sending the 8K test signal file name to the signal generation module; and the signal generation module is used for obtaining an 8K test signal file corresponding to the 8K test signal file name from the signal storage module and outputting the signal file. The memory occupied in the 8K signal output process is reduced, so that the running memory requirement of hardware is reduced. The invention also relates to an 8K test signal generation method, a storage medium and equipment.

Owner:MUDAN SHIYUAN ELECTRONICS BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com