A device and method for detecting the cross-sectional bending profile of a planar bending sheet metal part

A technology of plane bending and sheet metal parts, applied in measuring devices, optical devices, instruments, etc., can solve the problems of complex data acquisition and processing, poor accuracy of contour size data, high labor intensity, etc., and achieve convenient and efficient detection process. The effect of fast response and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

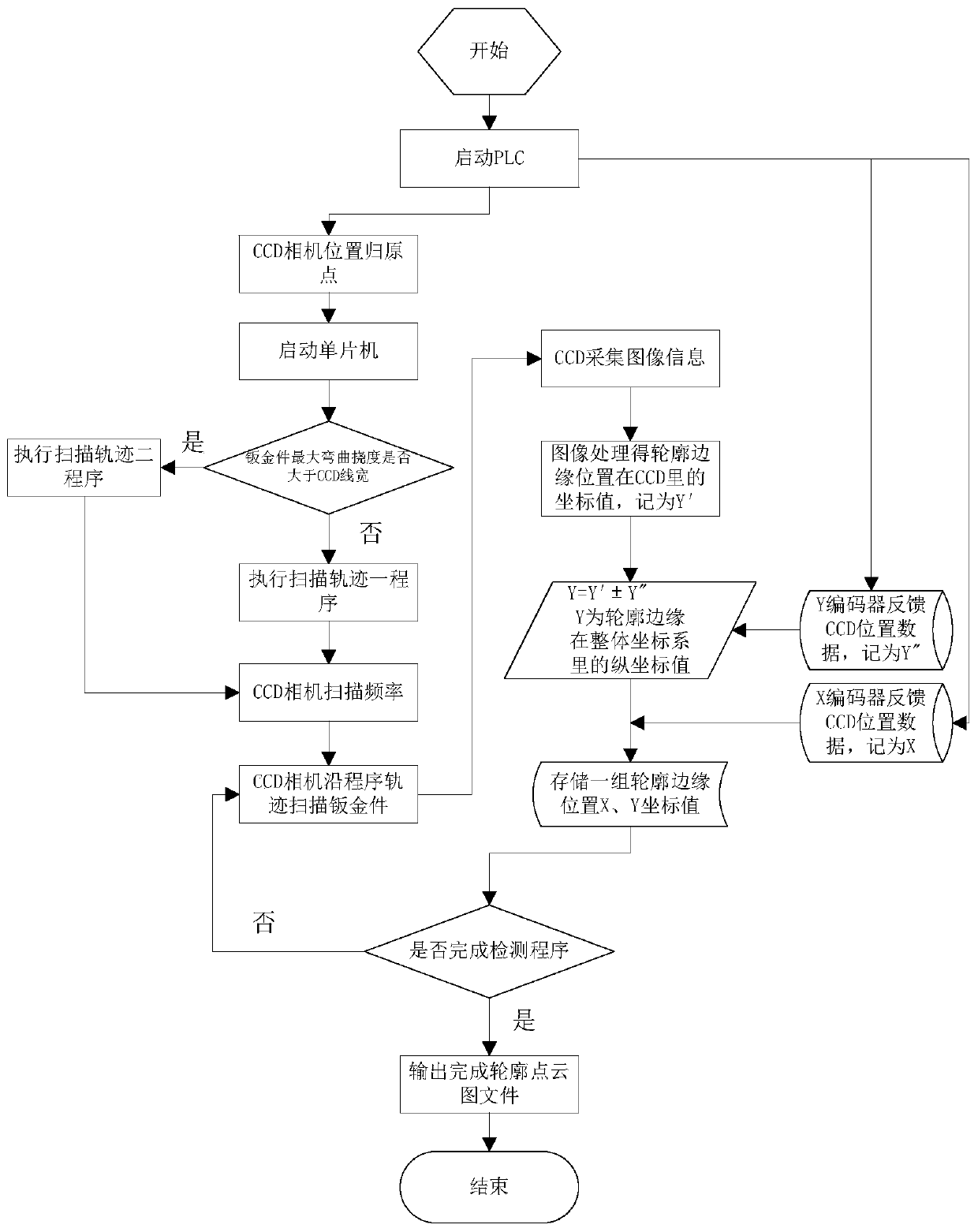

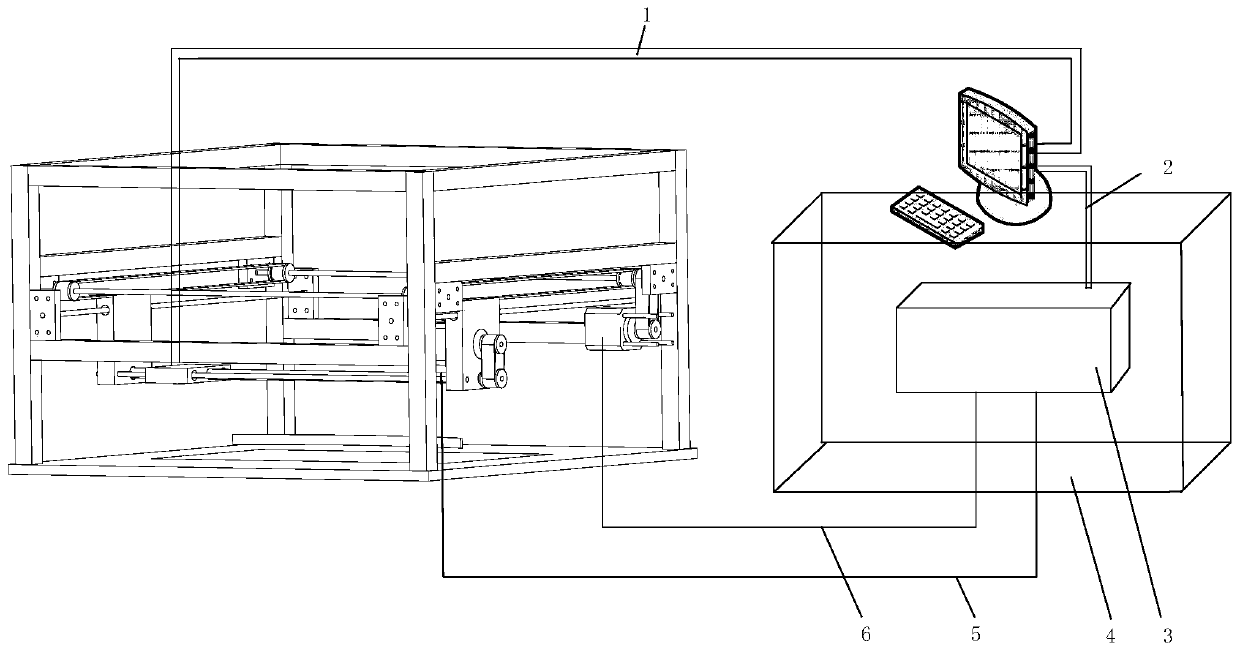

[0035] exist figure 2 In the schematic diagram of the detection device for bending contours of plane bending sheet metal parts shown, the detection device includes two parts: a mechanical device and a control device. Connect via Ethernet line 2, PLC connects to X module servo motor 20 via signal line A5, connects to Y module servo motor 16 via signal line via signal line B6, and connects to computer via data line 1 in the mechanical device. connect;

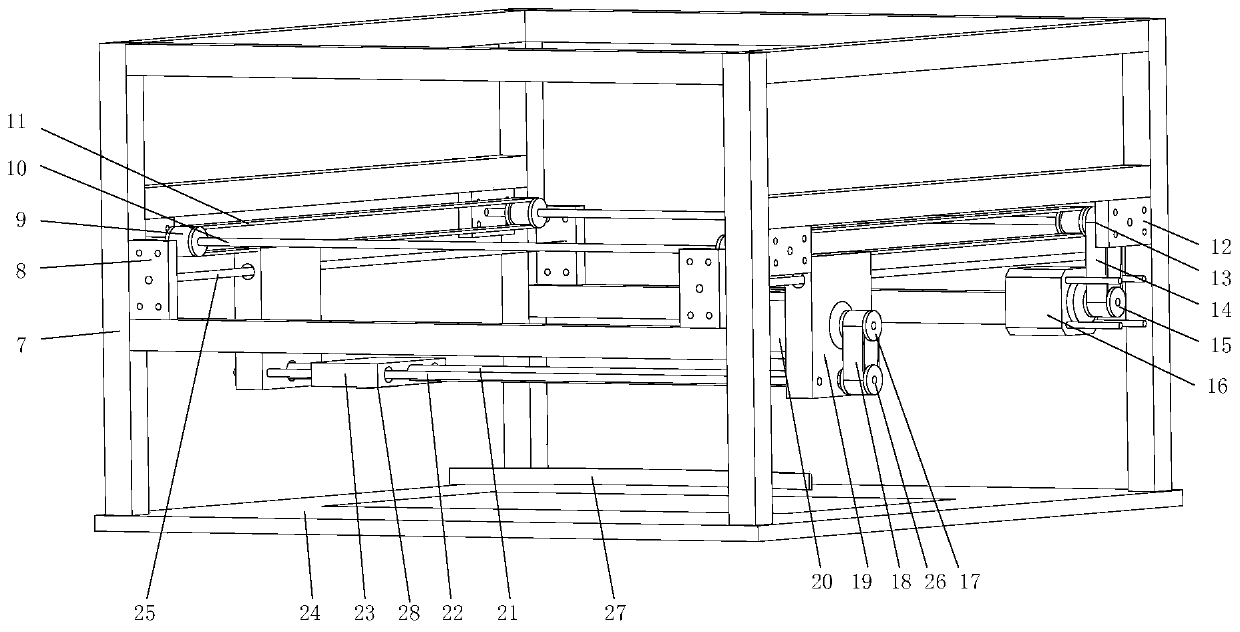

[0036] exist image 3 , Figure 4 , Figure 5 In the schematic diagram of the mechanical device for detecting the bending profile of a plane bending sheet metal part, the frame 7 is a cuboid frame in which the aluminum profiles are fixed by screws. The X-direction translation module and the Y-direction translation module are arranged inside the frame. The bottom of the frame is equipped with The workpiece supporting plate 24 fixedly connected with it is equipped with a light source system under the workpiece supporting plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com