Dust collection box type variable-frequency range hood and exhaust fume discharging method

A range hood, box-type technology, applied in the removal of oil fume, heating methods, household heating and other directions, can solve the problems of accumulation, oil fume, the angle of odor diffusion cannot be discharged, and it is not easy to clean, etc., to achieve the effect of enhancing the interactive effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

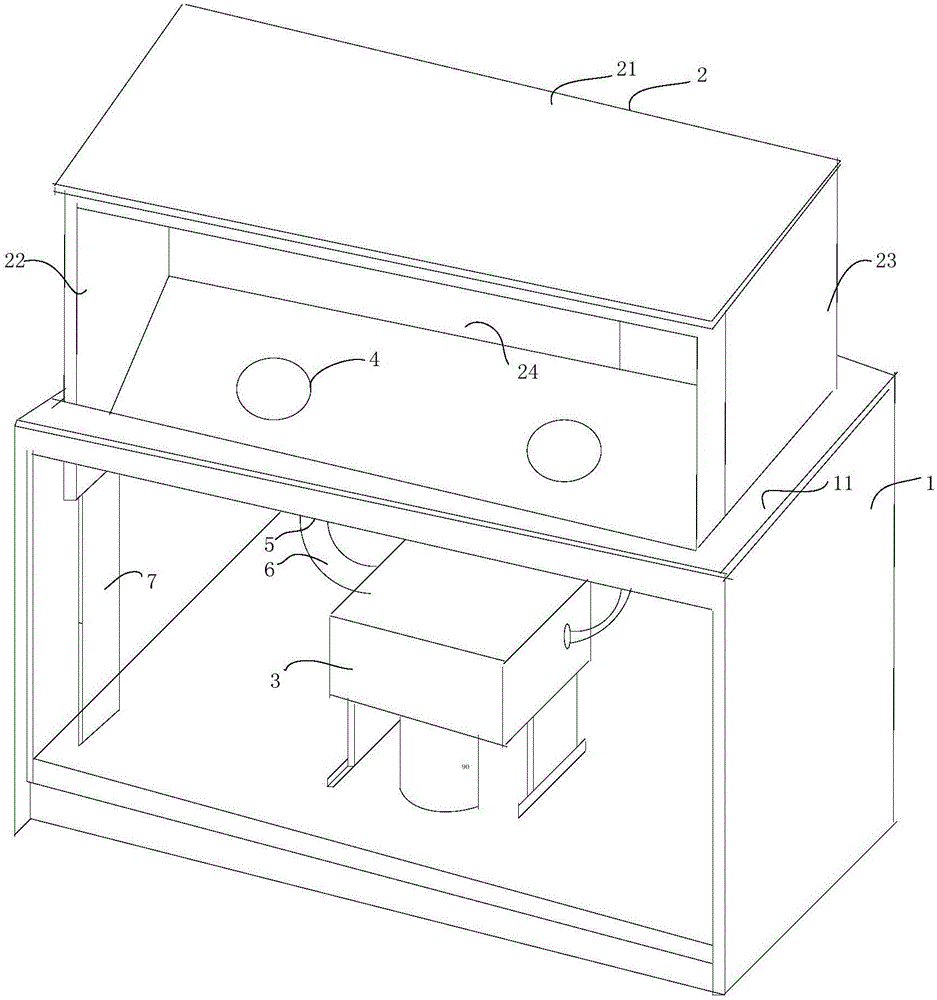

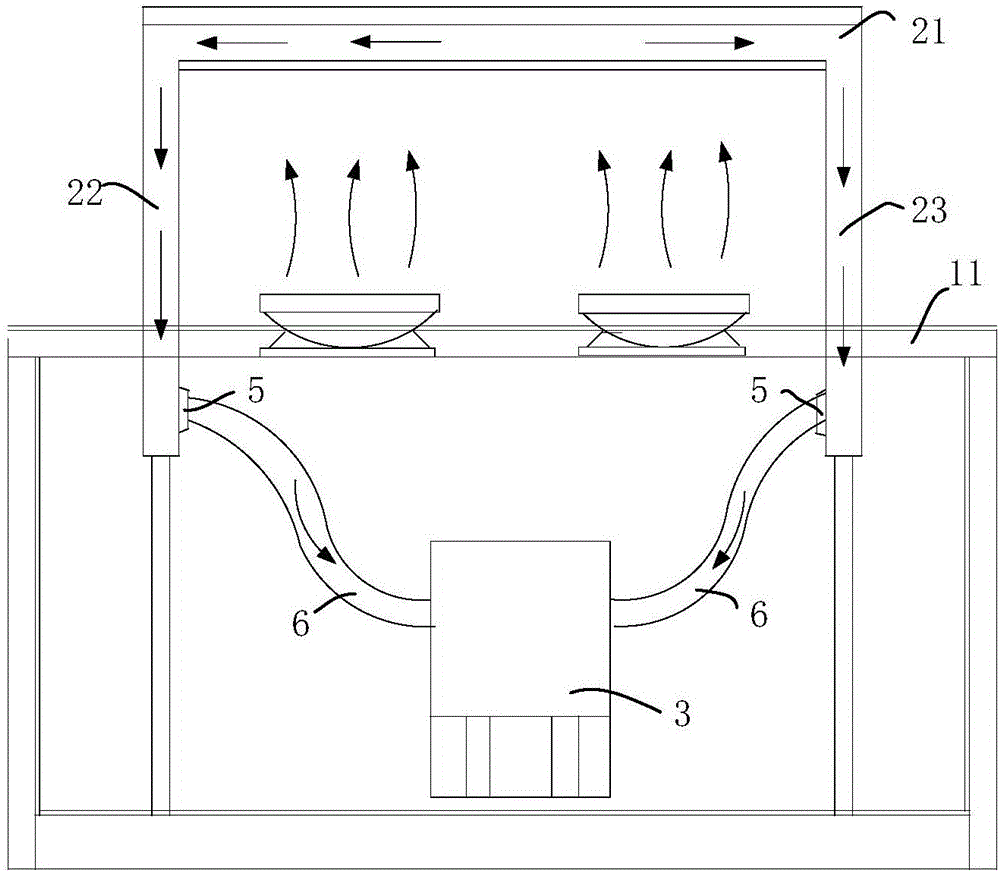

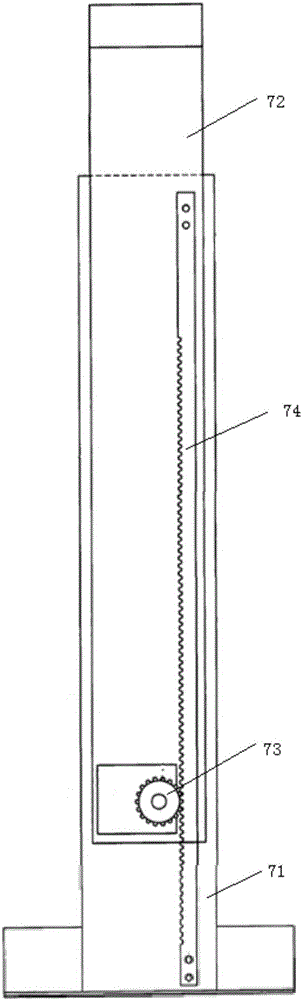

[0027] see Figure 1 to Figure 3 , The present invention provides a dust box-type frequency conversion range hood, which is arranged above the flow table 1 and includes an outer frame 2, a fan 3 and a lifting mechanism 7.

[0028] A U-shaped notch is opened on the flow management table 1, and the outer frame 2 is arranged in the notch.

[0029] The outer frame includes a top frame 21, a left side wall 22, a right side wall 23 and a rear side wall 24, the top frame 21 is located directly above the stove 4, and the top frame 21, the left side wall 22, the right side wall The side wall 23 and the rear side wall 24 jointly form an enclosed area with an upper part closed and side openings; the top frame 21, the left side wall 22, the right side wall 23 and the rear side wall 24 are all hollow and connected, and the A smoke outlet is opened on the left sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com