A thermometer calibration control method for oil pipelines in the petroleum industry

An oil pipeline and oil industry technology, which is applied in the field of thermometer calibration control for oil pipelines in the oil industry, can solve the problems of wasting processor resources, inconvenience, and increasing maintenance workload, and achieves the effect of reducing energy consumption and difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

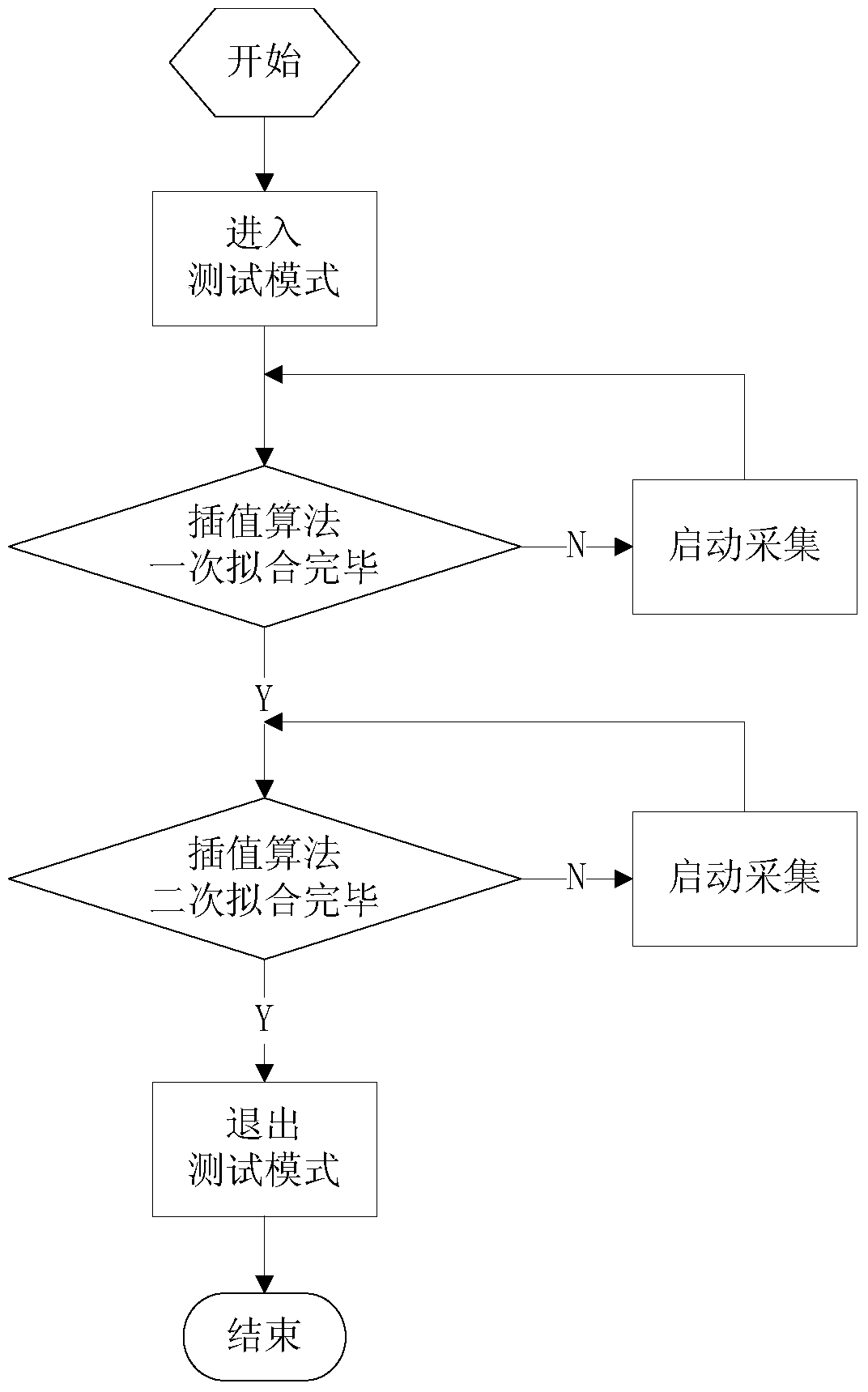

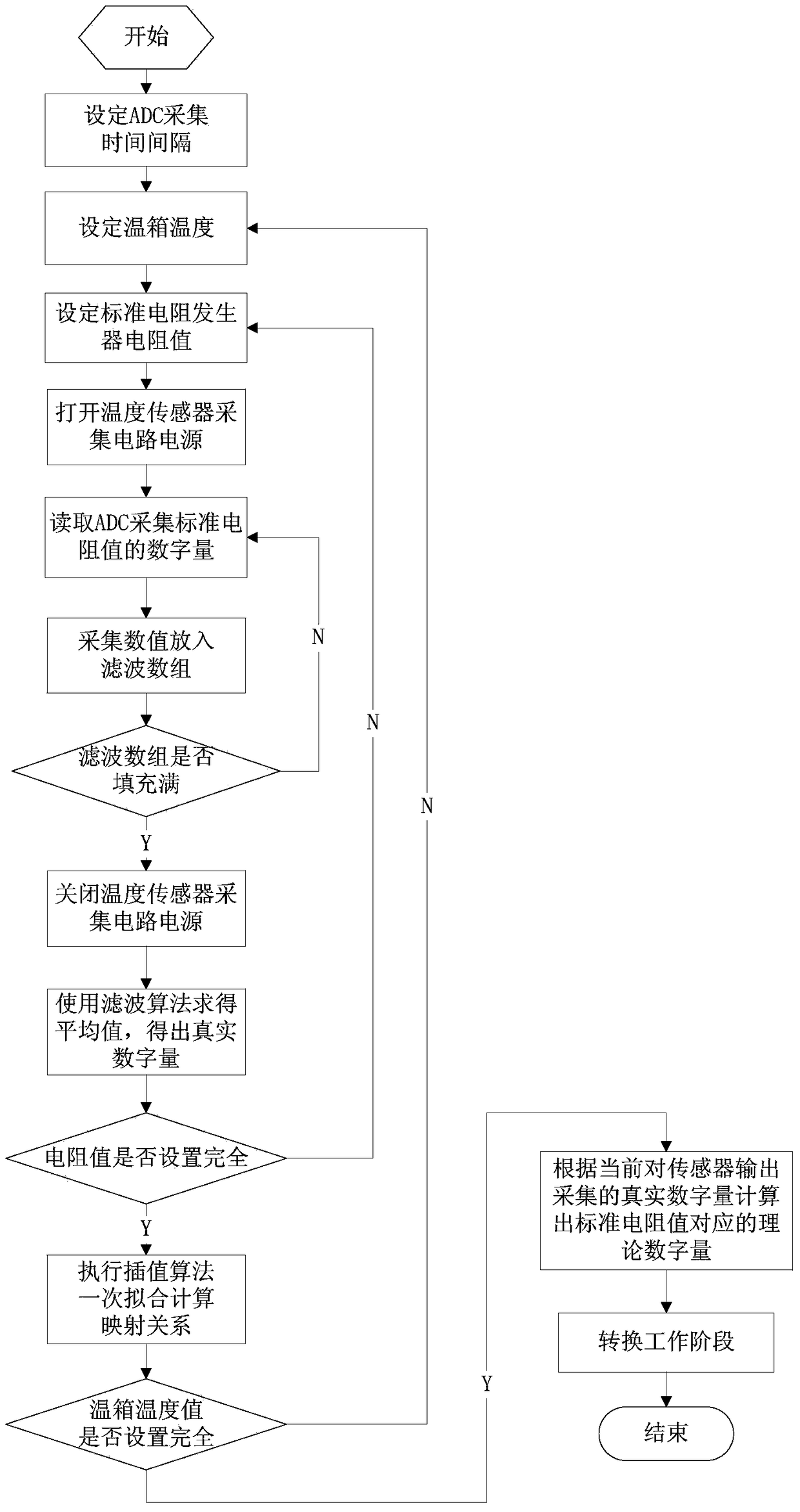

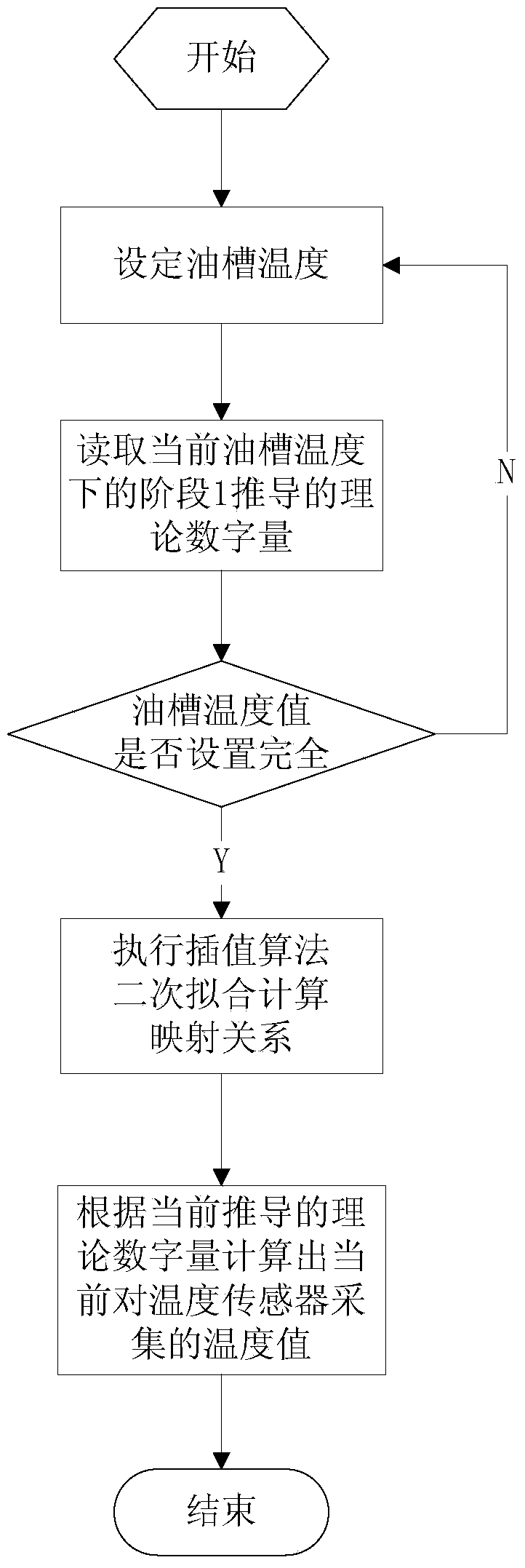

[0028] The purpose of the present invention is to provide a calibration method for the temperature gauge of the oil pipeline in the petroleum industry to obtain the mapping relationship between the digital quantity corresponding to the standard resistance value and the temperature value of the full range through interpolation calculation, without requiring additional system overhead. After the temperature meter system is powered on or reset, it enters the test mode, collects the real digital quantity output by the temperature sensor under different temperature conditions through the meter card ADC, and deduces the theoretical digital quantity. The temperature value of the current sensor is deduced from the theoretical digital quantity at different temperatures. This algorithm can reduce the influence of the heat conduction temperature of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com