Wiring terminal connector for LED

A terminal and connector technology, which is applied in the direction of connection, conductive connection, clamping/spring connection, etc., can solve the problems of complicated wiring, large bending force, and inconvenient off-line, so as to simplify the steps of wiring and off-line, Good elasticity and effect of applying force and simplifying operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

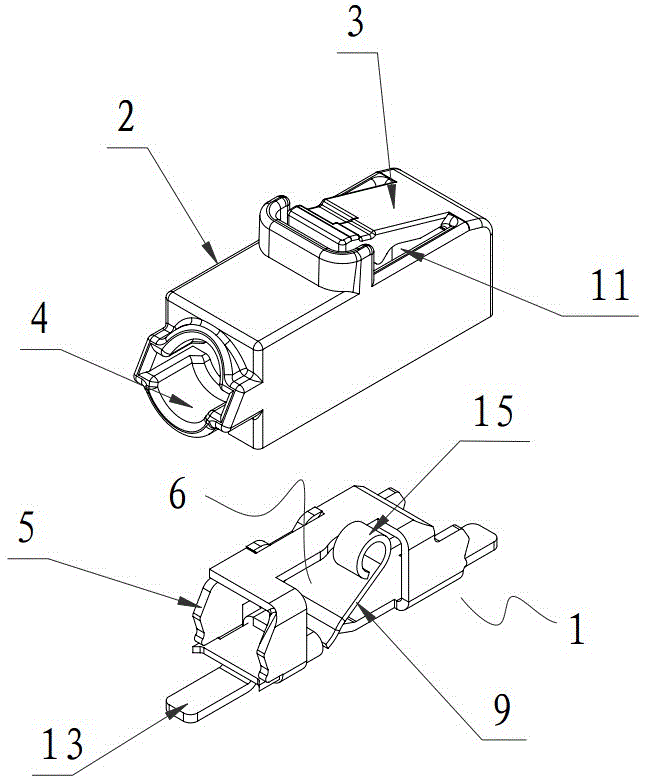

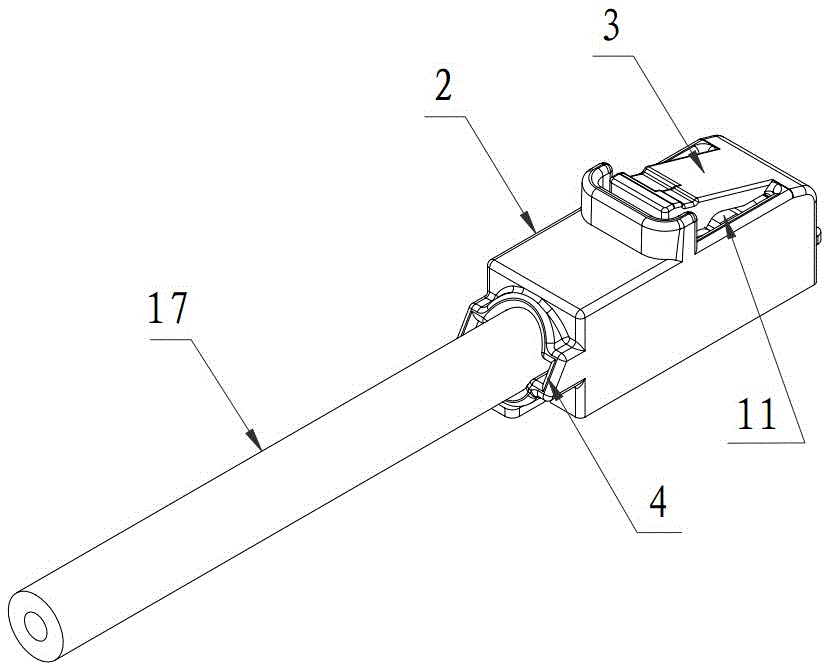

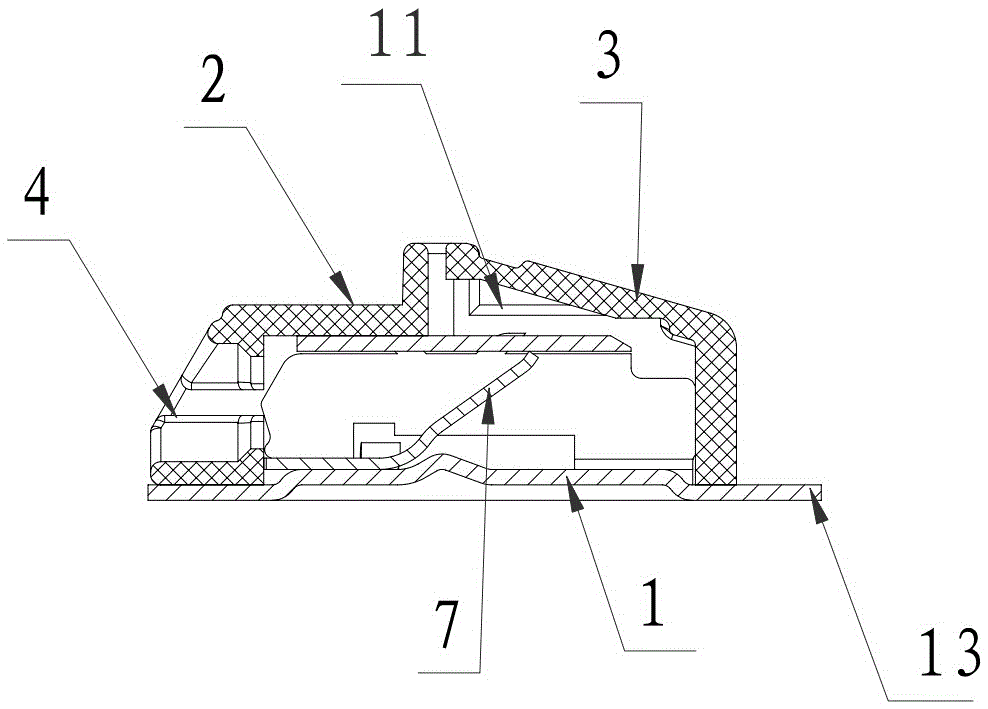

[0046] A terminal connector for LED described in Embodiment 1, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 and Figure 14 As shown, it includes a conductive metal clamping piece 1 arranged in the insulating housing 2 and a button 3 corresponding to the conductive metal clamping piece arranged on the insulating housing, the button and the insulating housing form an integral structure, and the front of the insulating housing is provided There is a wire socket 4 corresponding to the conductive metal clamping piece. The conductive metal clamping piece is composed of a frame-shaped wiring frame 5 and an elastic element 6 that is arranged on the frame-shaped wiring frame and cooperates with the frame-shaped wiring frame to realize clamping of the wire. The free end of the element constitutes a pointing wire 17 and cooperates with the inner top of the fr...

Embodiment 2

[0052] This embodiment 2 is improved on the basis of embodiment 1, and the specific improvement is double-strand wiring, as follows:

[0053] Such as Figure 15 , Figure 16 , Figure 17 , Figure 18 , Figure 19 , Figure 20 , Figure 21 and Figure 22 As shown, the insulating housing can be provided with two wire sockets, corresponding to the number of wire sockets in the insulating housing, two conductive metal clamping parts and two buttons are provided correspondingly.

Embodiment 3

[0055] Embodiment 3 is also improved on the basis of Embodiment 1, and the specific improvement is three-strand wire connection, as follows:

[0056] Such as Figure 23 , Figure 24 , Figure 25 , Figure 26 , Figure 27 , Figure 28 , Figure 29 and Figure 30 As shown, the insulating housing can be provided with three wire sockets, corresponding to the number of wire sockets in the insulating housing, there are three conductive metal clamping parts and three buttons are correspondingly provided. The cooperation between each conductive metal clamping piece and the button can clamp a corresponding wire separately. The use of each conductive metal clamping piece and button is not affected by other conductive metal clamping pieces and buttons. It is suitable for single Wiring of stranded and stranded conductors.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com