Glue pouring type insulating sealing butt joint method for underwater cable connection

A technology of insulation sealing and underwater cables, applied in the direction of cable joints, etc., can solve the problem that the sealing treatment and insulation treatment cannot meet the higher requirements, the sealing performance, corrosion resistance and practicability of the connection are poor, and the waterproof and insulation can not be achieved. , sealing and other issues, to achieve the effect of good sealing, good sealing protection and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] The glue-filling insulation sealing butt joint method for underwater cable connection involved in this embodiment specifically includes the following steps:

[0014] (1) First connect the matching No. I plug 2 and No. II plug 7 with the two ends of the sealing tube 3 respectively, and connect the repaired or cut-off two cable joints from No. I plug 2 and No. II respectively. The plug 7 penetrates from the outside to the inside, unscrew the No. 1 plug 2 or No. 2 plug 7, connect the two cable joints according to the standard cable wiring requirements, and wrap them with the wrapping tape 4;

[0015] (2) Place the wrapped cable joint in the center of the sealing tube 3, and then use SR plastic packing to seal the No. I threading hole 1 and the No. II threading hole 6 at both ends of the sealing tube 3; The sealing tube 3 is used to fill the gap between the outside of the wrapping tape 4 and the sealing tube 3, and finally the No. 1 plug 2 and the No. 2 plug 7 are tightened...

Embodiment 2

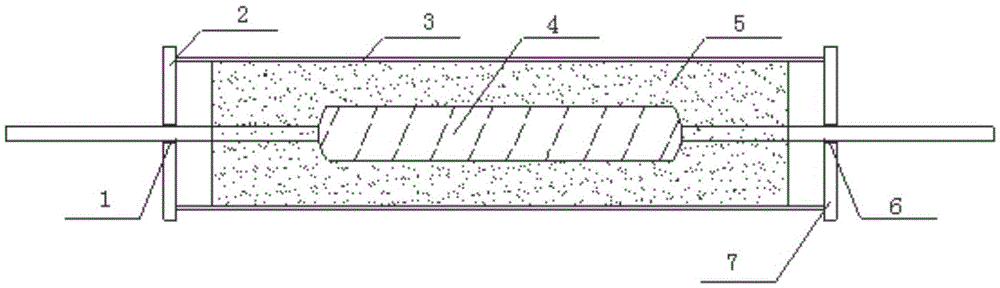

[0017] In this embodiment, the glue-filled insulating sealing butt joint method used for underwater cable connection in Example 1 is taken as an example, and the main structure of the finally formed glue-filling insulating sealing joint (such as figure 1 As shown) includes No. 1 threading hole 1, No. 1 plug 2, sealing tube 3, wrapping tape 4, sealant 5, No. 2 threading hole 6 and No. 2 plug 7, and 3 pairs of sealing tubes with cylindrical hollow structure No. Ⅰ plug 2 and No. Ⅱ plug 7 with the same structure are respectively installed in sealed type. Both No. Ⅰ plug 2 and No. Ⅱ plug 7 are PVC pipe plugs with spiral structure. The center of the plug 7 is provided with No. 1 threading hole 1 and No. 2 threading hole 6 respectively. The No. 1 threading hole 1 and the No. 2 threading hole 6 have the same structure and the same diameter; the center of the sealing tube 3 is covered with a broken cable connection The wrapping tape 4 is filled with sealant 5 in the gap between the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com