Photoluminescence-photothermal nano composite structural material and preparation method and application thereof

A nanocomposite and structural material technology, applied in luminescent/biological dyeing preparations, wave energy or particle radiation treatment materials, pharmaceutical formulations, etc., can solve the problems of difficult biological optical temperature detection, high price, toxicity, etc., and achieve major applications Foreground, High Accuracy, Low Side Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

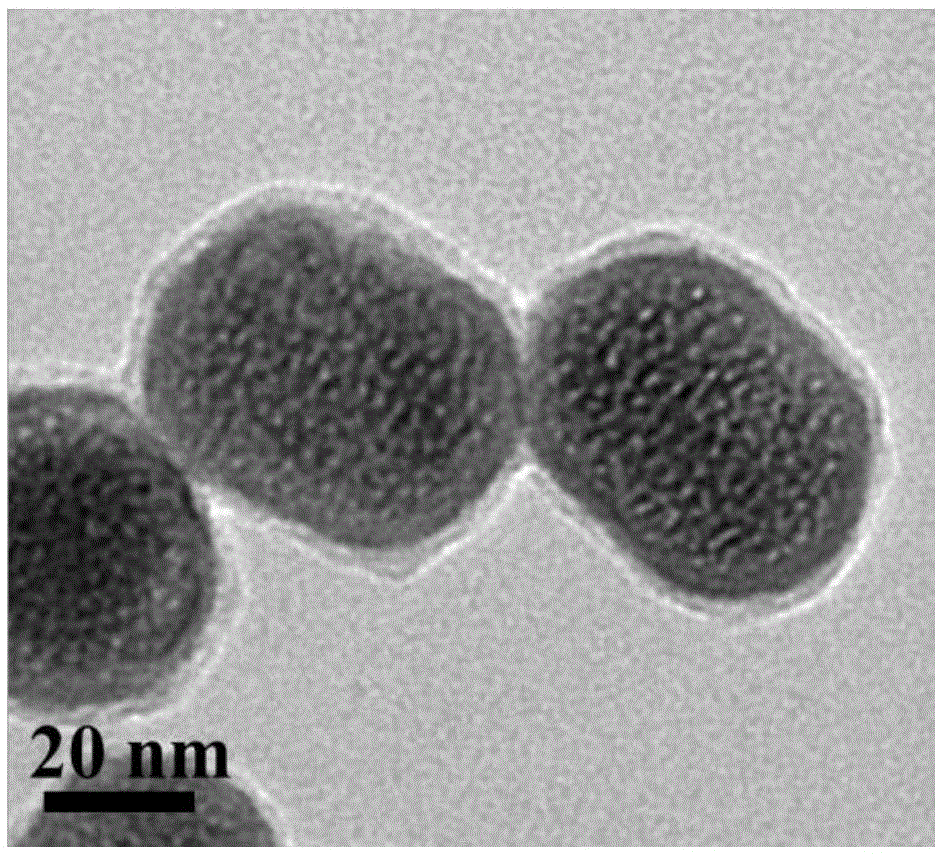

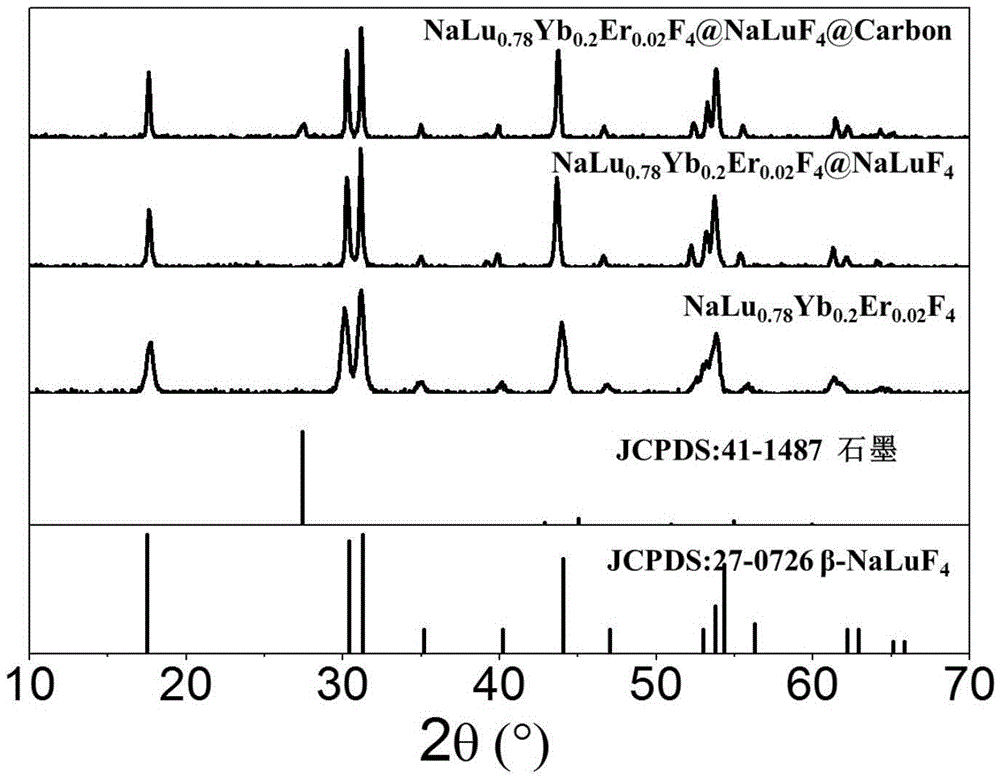

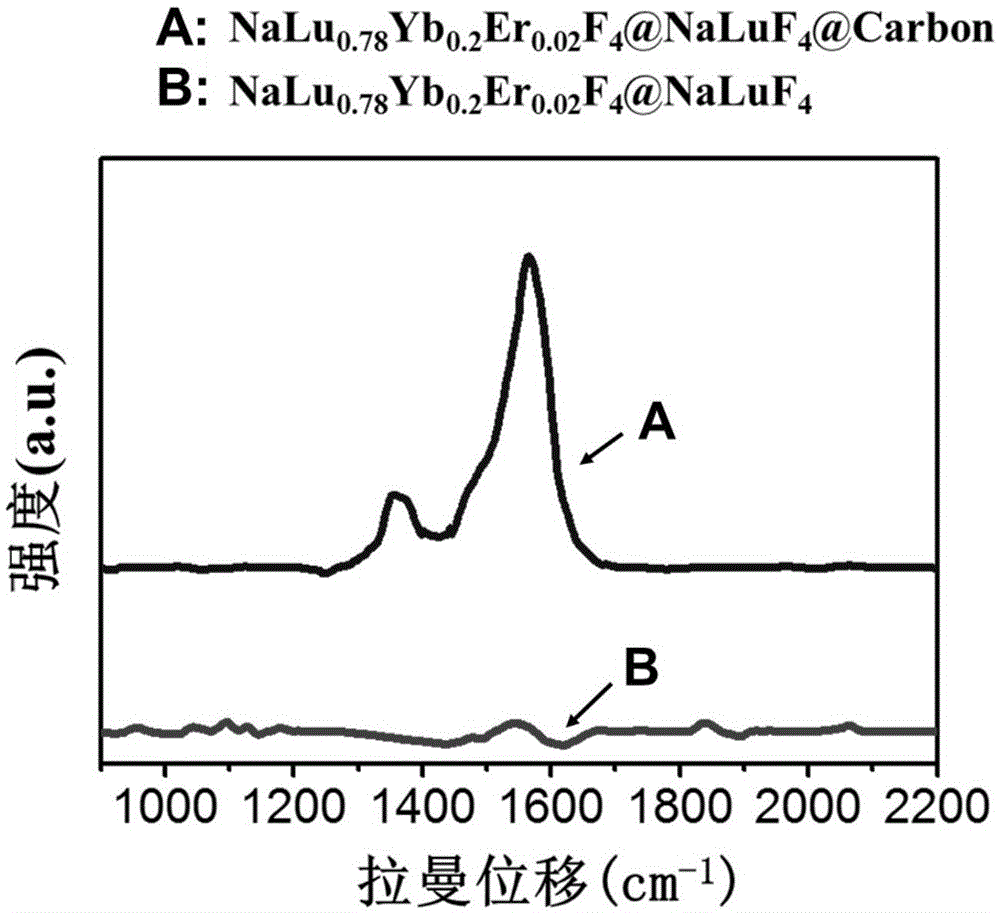

[0049] Example 1: NaLu 0.78 Yb 0.2 Er 0.02 f 4 NaLuF 4 Synthesis of Carbon

[0050] Weigh Lu(CF 3 COO) 3 0.78mmol, Yb(CF 3 COO) 3 0.2mmol, Er(CF 3 COO) 3 0.02mmol, Na(CF 3 COO) 3mmol, add solvent oleylamine 3mL, oleic acid 3mL, 1-octadecene 15mL, heat and stir at 90°C for 30 minutes to dissolve to form a homogeneous solution, and then open to evaporate water for 30 minutes. Under the protection of nitrogen atmosphere, the temperature was raised to 330° C., kept for 60 minutes, and then cooled to room temperature. The same volume of ethanol was added to the cooled solution, the solid was obtained by centrifugation, and the obtained solid was washed three times with a solution of ethanol:cyclohexane (1:1 v / v). Then weigh Lu(CF 3 COO) 3 1mmol, Na(CF 3 COO) 3 mmol, 6 mL of solvent oleic acid and 15 mL of 1-octadecene were added thereto, heated and stirred at 90° C. for 30 minutes to dissolve to form a homogeneous solution, and then the water was evaporated open for ...

Embodiment 2

[0051] Example 2: LiY 0.35 Yb 0.05 Nd 0.6 f 4 YF 4 Synthesis of Polypyrrole

[0052] Weigh Y(CF 3 COO) 3 0.35mmol, Yb(CF 3 COO) 3 0.05mmol, Nd(CF 3 COO) 3 0.6mmol, Li(CF 3 COO) 2mmol, add solvent oleylamine 3mL, oleic acid 3mL, 1-octadecene 15mL, heat and stir at 90°C for 30 minutes to dissolve to form a homogeneous solution, and then open to evaporate water for 30 minutes. Under the protection of nitrogen atmosphere, the temperature was raised to 310° C., kept for 60 minutes, and then cooled to room temperature. The same volume of ethanol was added to the cooled solution, the solid was obtained by centrifugation, and the obtained solid was washed three times with a solution of ethanol:cyclohexane (1:1 v / v). Then weigh Y(CF 3 COO) 3 1mmol, Li(CF 3 COO) 2mmol, add 6mL of solvent oleic acid, 15mL of 1-octadecene, heat and stir at 80~100°C for 30 minutes to dissolve to form a homogeneous solution, and then evaporate the water for 30 minutes. Add the solid obtained...

Embodiment 3

[0053] Example 3: LiLu 0.95 Nd 0.05 f 4 LiF 4 Synthesis of PEDOT

[0054] Weigh Lu(CF 3 COO) 3 0.95mmol, Nd(CF 3 COO) 3 0.05mmol, Li(CF 3 COO) 3mmol, add 3mL of solvent oleylamine, 3mL of oleic acid, 15mL of 1-octadecene, heat and stir at 90°C for 30 minutes to dissolve to form a uniform solution, and then evaporate the water for 30 minutes. Under the protection of nitrogen atmosphere, the temperature was raised to 330° C., kept for 60 minutes, and then cooled to room temperature. The same volume of ethanol was added to the cooled solution, the solid was obtained by centrifugation, and the obtained solid was washed three times with a solution of ethanol:cyclohexane (1:1 v / v). Then weigh Lu(CF 3 COO) 3 1mmol, Li(CF 3 COO) 3 mmol, 6 mL of solvent oleic acid and 15 mL of 1-octadecene were added thereto, heated and stirred at 90° C. for 30 minutes to dissolve to form a homogeneous solution, and then the water was evaporated open for 30 minutes. Add the solid obtained ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Power density | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com