Binding post shunted connector

A terminal and connector technology, used in connection, conductive connection, electrical component connection, etc., can solve the problems of reducing wiring efficiency, labor intensity, and short service life, achieving high construction efficiency, easy wiring work, Easy off-line effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

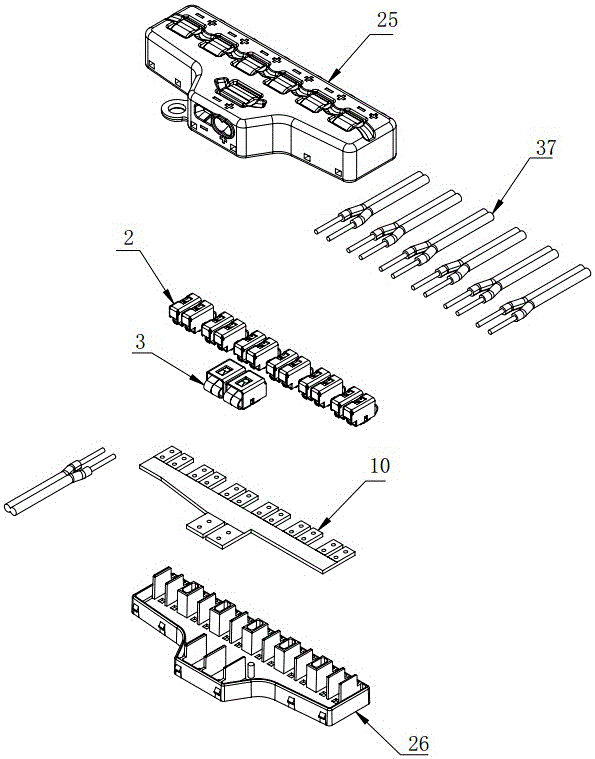

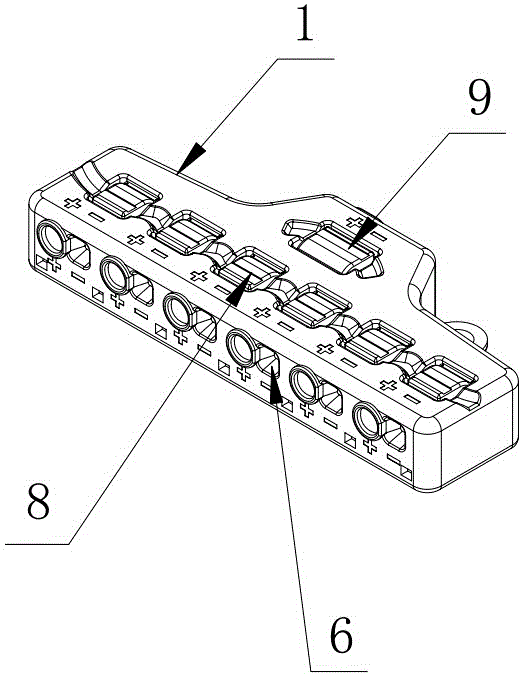

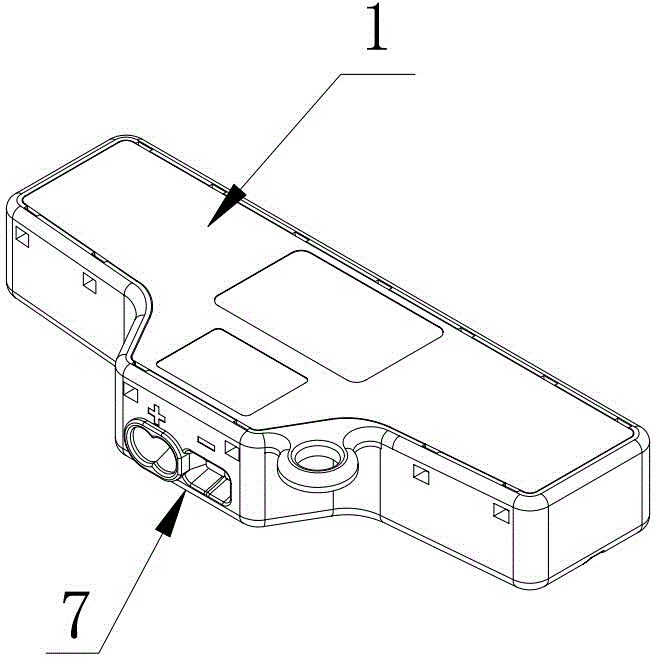

[0050] A terminal shunt connector described in Embodiment 1 of the present invention, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 , Figure 18 , Figure 19 and Figure 20 As shown, it includes an insulating housing 1 and a first conductive metal component 2 and a second conductive metal component 3 installed in the insulating housing. The insulating housing is provided with a first fixing component 4 for fixing the first conductive metal component and a second conductive metal component for fixing. For the second fixing component 5 of the metal component, the front part of the insulating housing is provided with a first socket group 6 corresponding to the first fixing component and the first conductive metal component, and the rear part of the insulating housing is provided with a correspond...

Embodiment 2

[0057] This embodiment 2 is changed on the basis of embodiment 1. Specifically, the structures of the insulating casing, the first button button and the second push button are different, as follows:

[0058] Such as Figure 21 , Figure 22 , Figure 23 , Figure 24 , Figure 25 , Figure 26 , Figure 27 , Figure 28 , Figure 29 , Figure 30 and Figure 31 As shown, the insulating housing is composed of a front housing 31 and a rear housing 32, the conductive connecting plate and the second fixing assembly are arranged in the front housing, and the first fixing assembly is arranged on the rear housing; the first fixing assembly consists of the upper The first through-slot 33 and the lower part can separate two side-by-side symmetrical first metal frames to form a first partition 34 that does not directly contact. Slot 35, the first push button can press the first metal frame through the first button installation groove and the first through groove; the second fixing ...

Embodiment 3

[0060] Embodiment 3 is changed on the basis of Embodiment 1 and Embodiment 2. Specifically, the number of groups of related components such as the first conductive metal component is different, as follows:

[0061] Such as Figure 32 and Figure 33 As shown, the number of groups of the first conductive metal component is three groups, and the corresponding first group of wire sockets is different from the structure of the insulating shell, that is, a three-position terminal shunt connector with its own button and independent button structure.

[0062] Such as Figure 34 and Figure 35 As shown, the number of groups of the first conductive metal component is nine groups, and the corresponding first group of wire sockets is different from the structure of the insulating shell, that is, it is a terminal shunt connector with a nine-position structure, each with its own button and independent button structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com