Plug-in type wiring terminal connector

A terminal and connector technology, used in connection, conductive connection, clamping/spring connection, etc., can solve the problems of reduced labor intensity, short service life, reduced wiring efficiency, etc., and achieve simple and stable wiring work. , the effect of high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

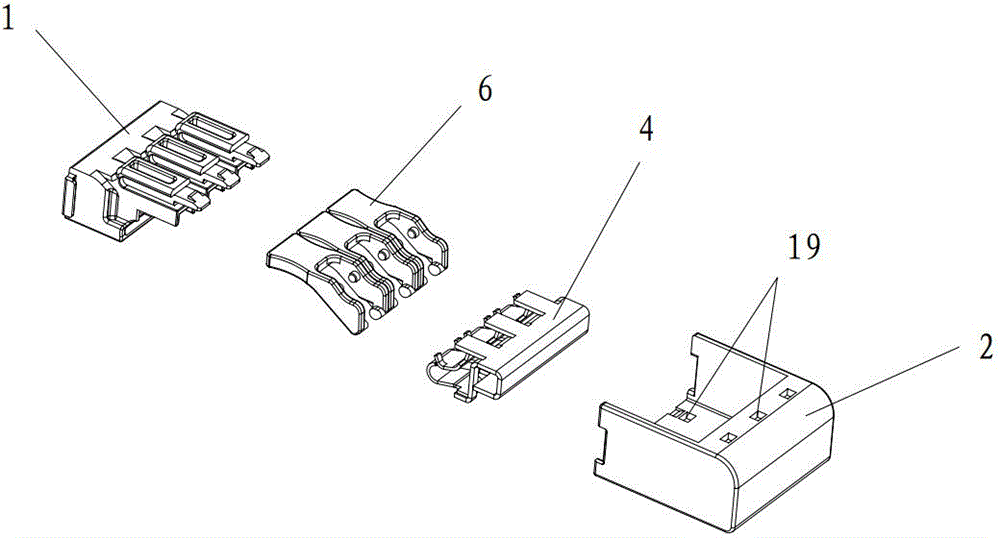

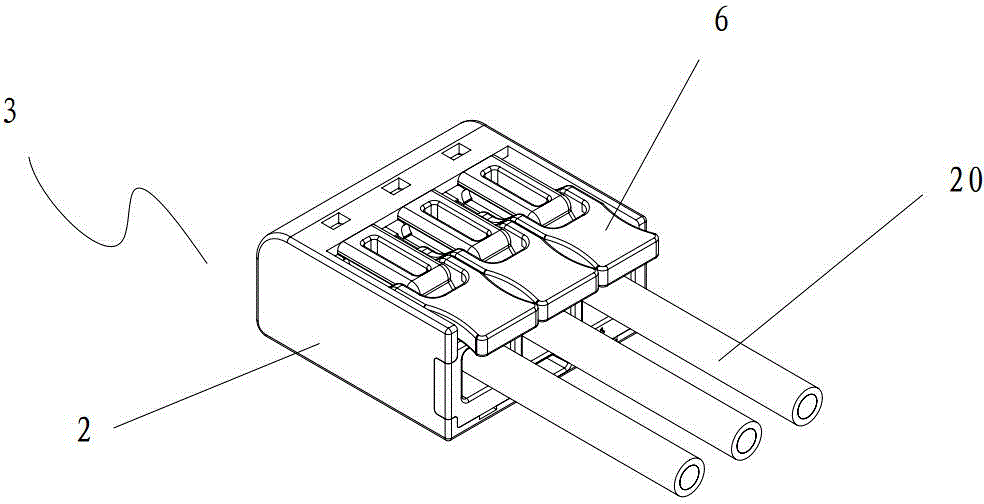

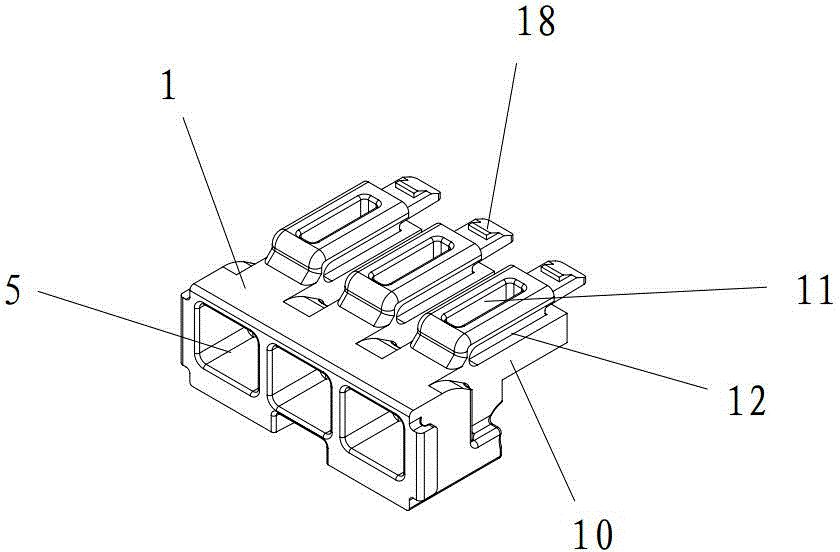

[0036] A plug-in terminal connector described in Embodiment 1 of the present invention, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 , Figure 17 , Figure 18 , Figure 19 , Figure 20 , Figure 21 , Figure 22 , Figure 23 , Figure 24 , Figure 25 and Figure 26 As shown, it includes an insulating housing 3 composed of a front housing 1 and a rear housing 2 with a cavity. The insulating housing is provided with a conductive metal component 4 installed in the cavity, and the front end of the front housing is provided with a corresponding conductive metal assembly. The plug-in port 5 of the component also includes a pull-out cover 6 arranged on the top of the insulating shell, and the conductive metal component is composed of a front elastic metal sheet 7 corresponding to the plug-in port and a rear m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com