SCR-based Split Modular Drive Controller

A drive controller and modular technology, applied in the field of automation, can solve the problems of high maintenance cost and high circuit design cost, and achieve the effects of reliable triggering, avoiding weak current burnout, and reducing production risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

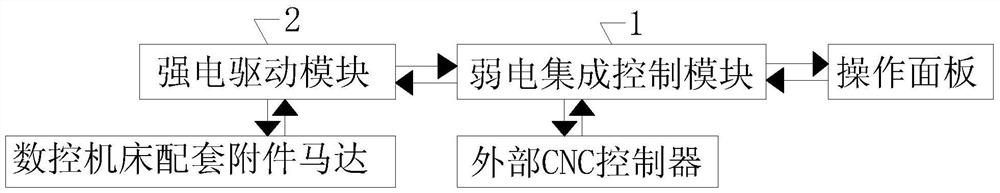

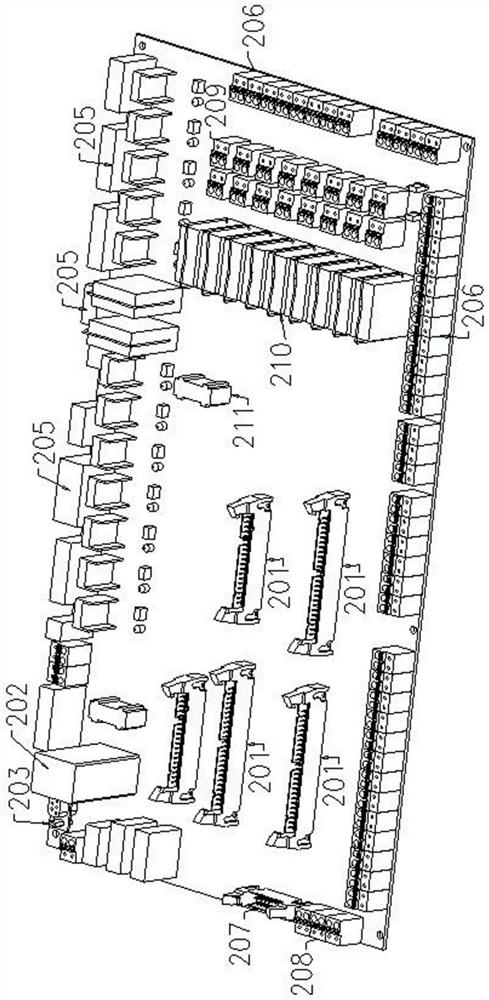

[0029] refer to figure 1 , the thyristor-based split modular drive controller of this embodiment includes a strong current drive module 2 and a weak current integrated control module 1, the strong current drive module 2 is connected to the accessory motor of the CNC machine tool, and the weak current integrated control module 1 is connected to To the external CNC controller and operation panel, the strong current drive module 2 is provided with a weak current board connection transfer port 101, the weak current integrated control module 1 is provided with a strong current board communication port 207, and the strong current board communication port 207 is connected to the weak current board Connect the transfer port 101 connection.

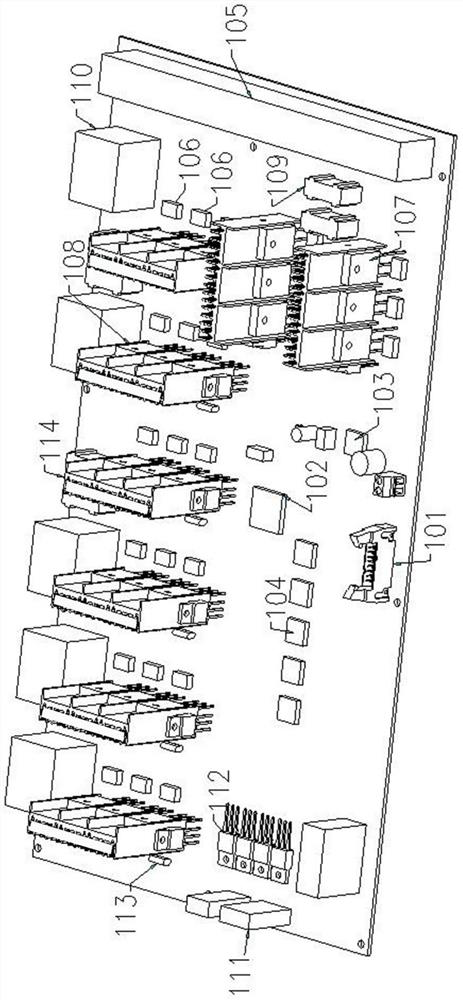

[0030] refer to figure 2, In another embodiment, the strong current drive module 2 includes a single chip microcomputer 102, a control loop 103, a strong current input port 105, a strong current output port 110, an amplifier, an amplifier driver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com