Preparation method of sheet-type carbonyl iron powder microwave absorber

A microwave absorbing agent, carbonyl iron powder technology, applied in the direction of magnetic materials, inorganic material magnetism, electrical components, etc., can solve the problems of impedance mismatch, wave absorption performance decline, dielectric constant increase, etc., to achieve magnetic loss and dielectric constant. The effect of increased loss, increased length-to-thickness ratio, and increased ball-to-material ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

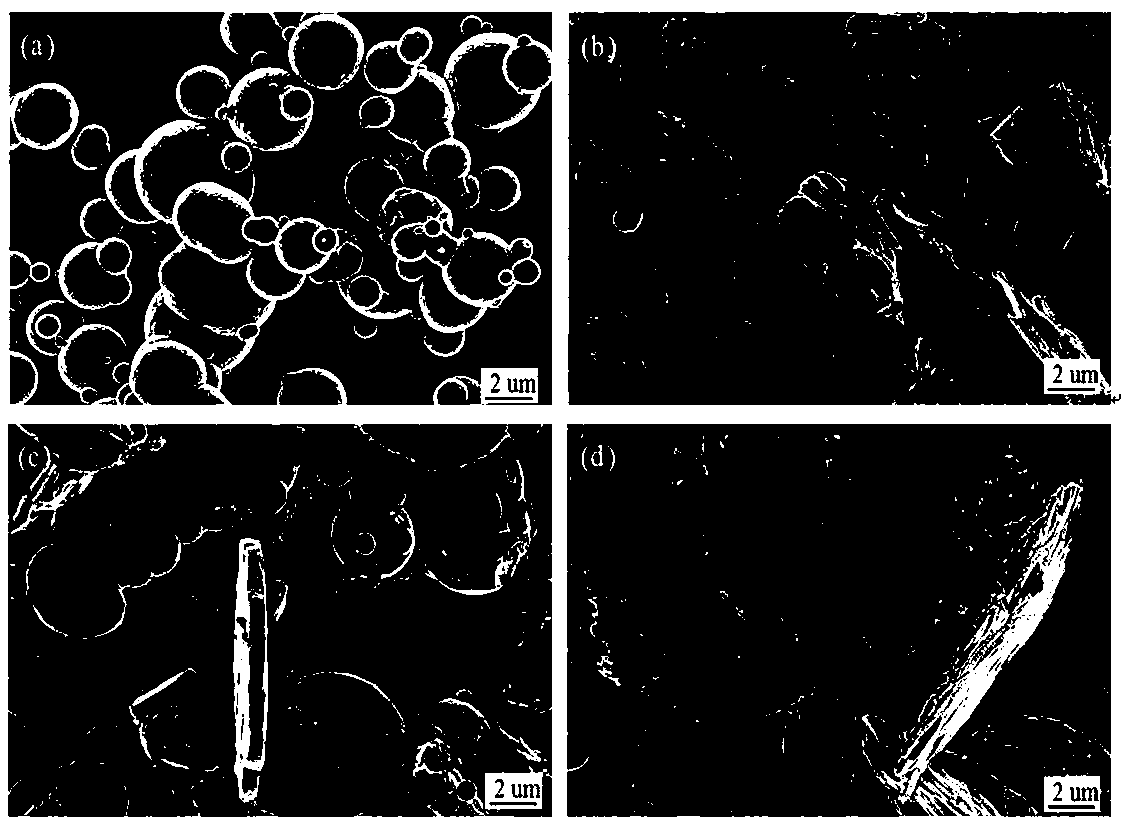

Embodiment 1

[0033] (1) Add 60 kg of zirconia grinding balls with a diameter of 6 mm and 2 kg of spherical carbonyl iron powder with an average particle size of 3 μm into a stainless steel vacuum grinding tank lined with alumina, and then add 10 L of absolute ethanol as a morphology control agent.

[0034] (2) Vacuum the grinding tank and replace it with nitrogen, and then carry out wet stirring ball milling under the protection of nitrogen, with a stirring speed of 260 rpm and a grinding time of 8 hours.

[0035] (3) Filter the spherical micron carbonyl iron powder after ball milling, collect the solid and vacuum-dry it at 60°C for 12 hours, and pass high-purity nitrogen gas every 3 hours to replace the volatilized anhydrous ethanol, and then re-evacuate.

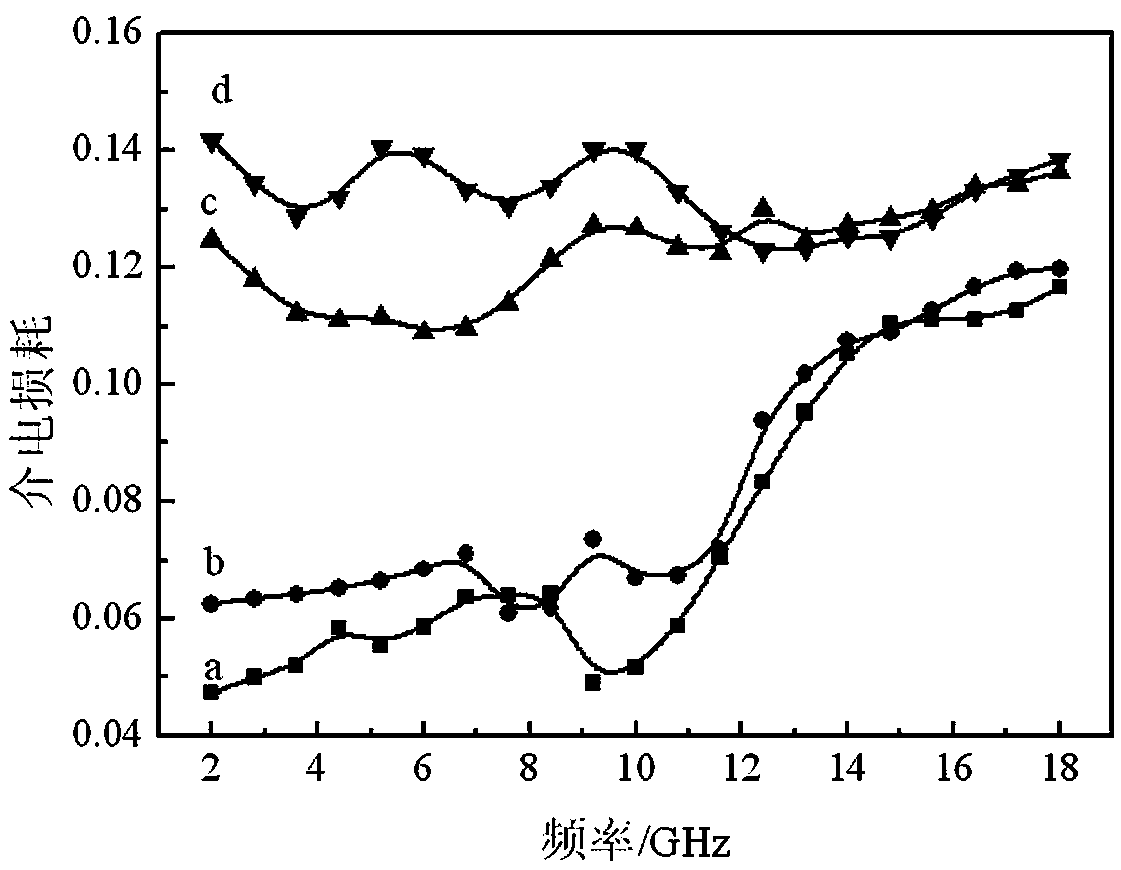

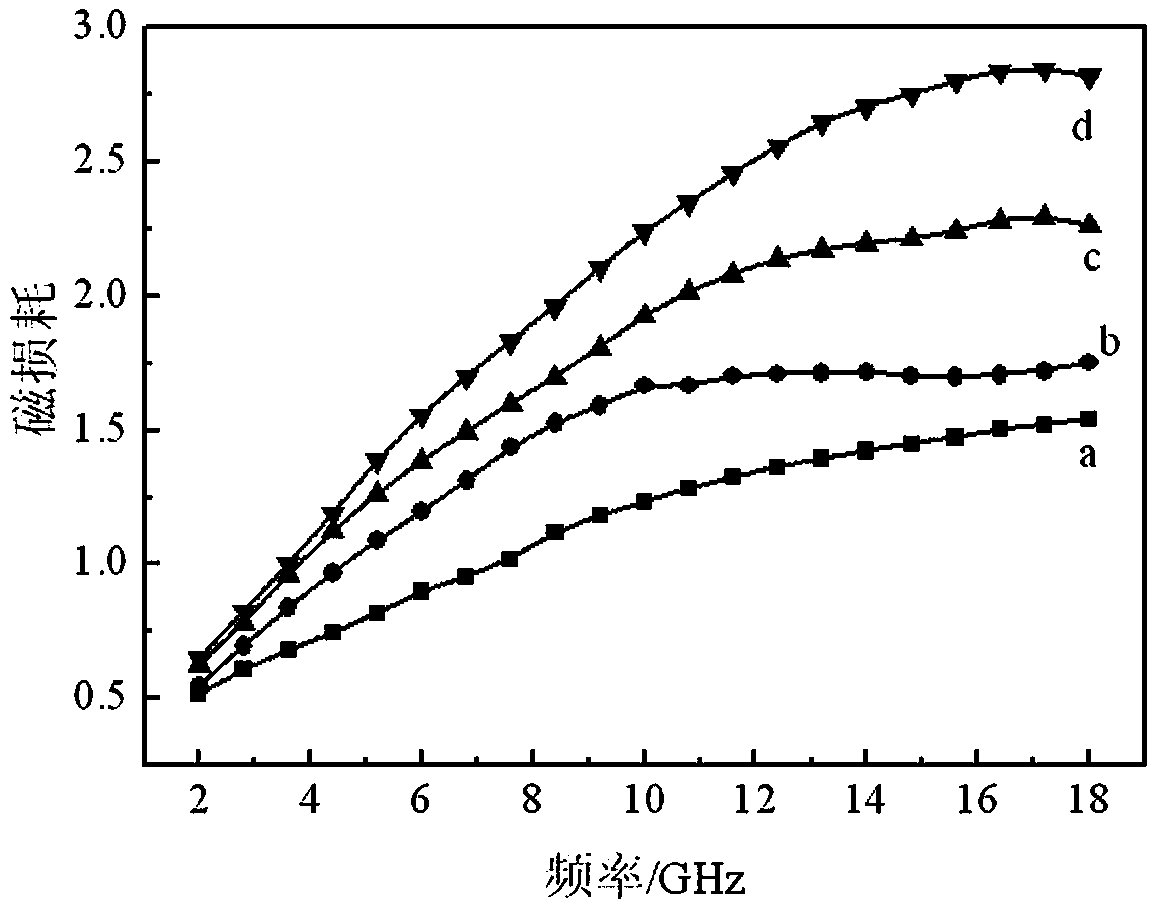

[0036] (4) Under the protection of nitrogen, the dried powder was subjected to airflow milling for ultrafine dispersion, and airflow milling at a pressure of 0.4 MPa for 15 minutes. The obtained monodisperse flake-shaped carbonyl iron ...

Embodiment 2

[0039] (1) Add 120 kg of zirconia grinding balls with a diameter of 6 mm and 2 kg of spherical carbonyl iron powder with an average particle size of 3 μm into a stainless steel vacuum grinding tank lined with alumina, and then add 15 L of absolute ethanol as a shape control agent.

[0040] (2) Vacuumize the grinding tank and replace it with nitrogen, and then carry out wet stirring ball milling under the protection of nitrogen, with a stirring speed of 260rpm and a stirring time of 10h.

[0041] (3) Filter the spherical micron carbonyl iron powder after ball milling, collect the solid and vacuum-dry it at 60°C for 12 hours, and pass high-purity nitrogen gas every 3 hours to replace the volatilized anhydrous ethanol, and then re-evacuate.

[0042] (4) Then, under the protection of nitrogen, the dried powder was subjected to airflow milling for ultrafine dispersion, and airflow milling at a pressure of 0.6MPa for 10 minutes. The obtained monodisperse flake carbonyl iron powder h...

Embodiment 3

[0045] (1) Add 180 kg of zirconia grinding balls with a diameter of 6 mm and 2 kg of spherical carbonyl iron powder with an average particle size of 3 μm into a stainless steel vacuum grinding tank lined with alumina, and then add 20 L of absolute ethanol as a shape control agent.

[0046] (2) Vacuum the grinding tank and replace it with nitrogen, and then carry out wet stirring ball milling under the protection of nitrogen, with a grinding speed of 260 rpm and a grinding time of 12 hours.

[0047] (3) Filter the spherical micron carbonyl iron powder after ball milling, collect the solid and vacuum-dry it at 60°C for 12 hours, and pass high-purity nitrogen gas every 3 hours to replace the volatilized anhydrous ethanol, and then re-evacuate.

[0048] (4) Under the protection of nitrogen, the dried powder is subjected to airflow milling for ultrafine dispersion, and airflow milling at a pressure of 0.5 MPa for 12 minutes. The obtained monodisperse flake carbonyl iron powder has ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com