A kind of low density, super high specific yield strength mg-ni-ti-al quaternary alloy and preparation method thereof

A yield strength, quaternary alloy technology, applied in the field of multi-element alloy materials and their processing, can solve the problems of low absolute value of strength and low matrix strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

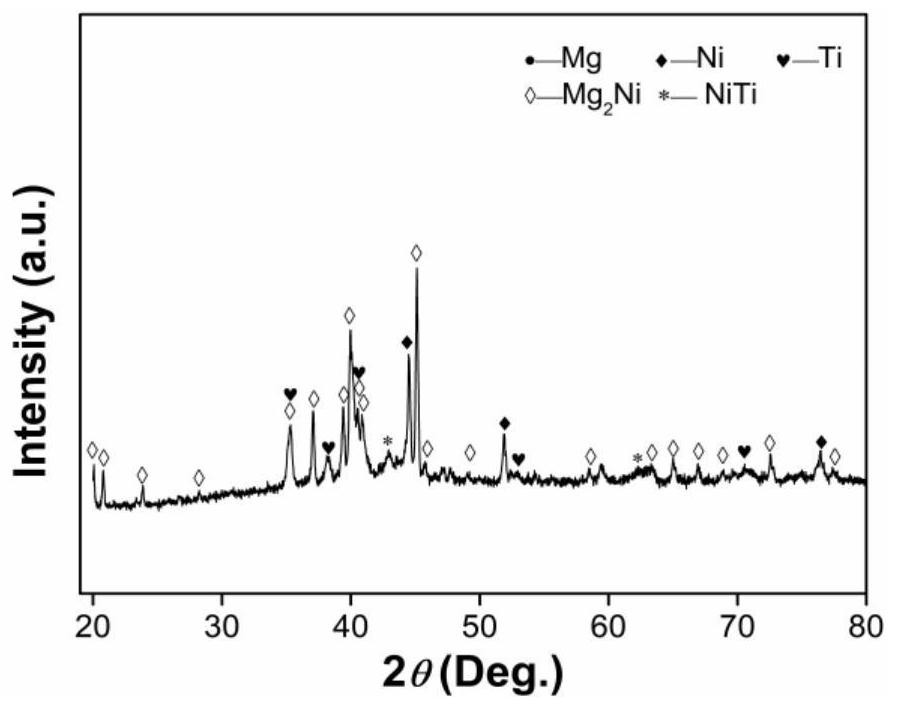

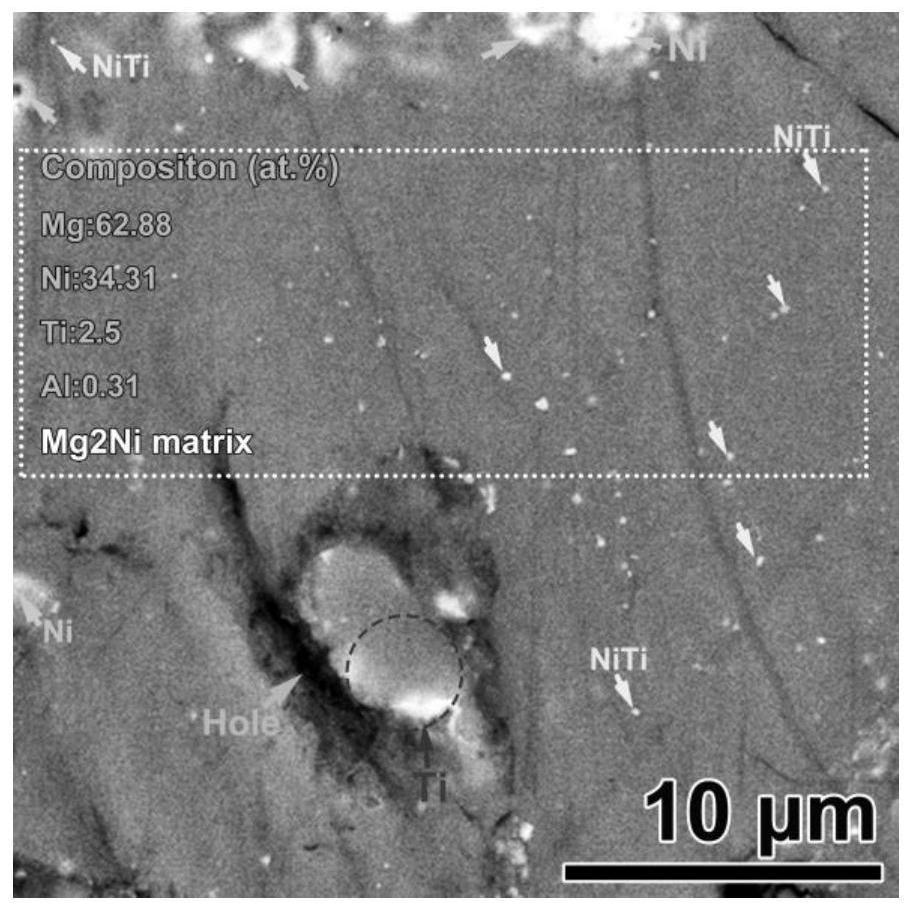

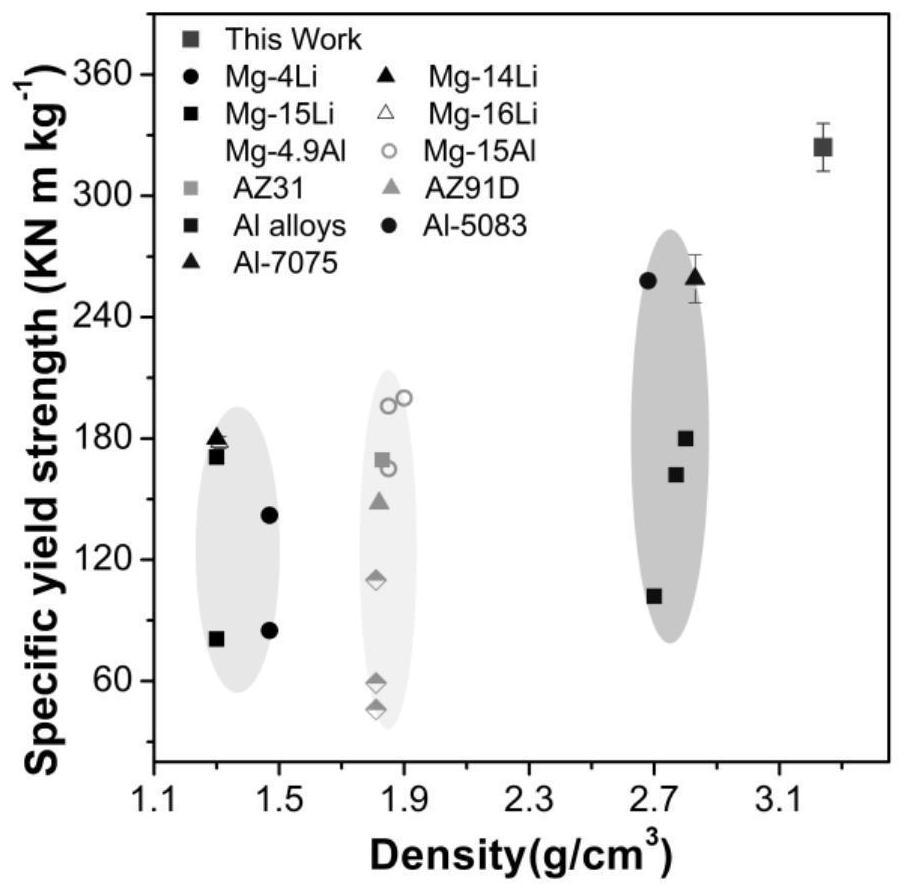

[0044] A kind of low density, ultra-high specific yield strength Mg-Ni-Ti-Al quaternary alloy of the present embodiment, the chemical composition of described alloy is expressed as Mg by atomic ratio 1.9 NiTiAl 0.1 , the microstructure of the alloy is based on Mg 2 Ni is the parent phase, and a large number of nanoscale strengthening phases are dispersed in the alloy, and the strengthening phase is a B2-NiTi intermetallic compound; wherein: the density of the alloy is 3.24g / cm 3 , the average specific yield strength is 324MPa·cm 3 / g, the average hardness of the alloy is 3.15GPa.

[0045] The low-density, ultra-high specific yield strength Mg-Ni-Ti-Al quaternary alloy described above in this embodiment is prepared by the following method, and the steps are as follows:

[0046] (1) Material preparation:

[0047] The high-purity (above 3.5N) Mg, Ni, Ti and Al metal powders used have a uniform particle size and should be less than 48 μm (300 mesh). The process control agent i...

Embodiment 2

[0056] A kind of low density, ultra-high specific yield strength Mg-Ni-Ti-Al quaternary alloy of the present embodiment, the chemical composition of described alloy is expressed as Mg by atomic ratio 1.9 NiTiAl 0.1 , the microstructure of the alloy is based on Mg 2 Ni is the parent phase, and a large number of nanoscale strengthening phases are dispersed in the alloy, and the strengthening phase is a B2-NiTi intermetallic compound; wherein: the density of the alloy is 3.24g / cm 3 , the average specific yield strength is 312.2MPa·cm 3 / g, the average hardness of the alloy is 3.03GPa.

[0057] The low-density, ultra-high specific yield strength Mg-Ni-Ti-Al quaternary alloy described above in this embodiment is prepared by the following method, and the steps are as follows:

[0058] (1) Material preparation:

[0059] The high-purity (above 3.5N) Mg, Ni, Ti and Al metal powders used have a uniform particle size and should be less than 48 μm (300 mesh). The process control agent...

Embodiment 3

[0066] A kind of low density, ultra-high specific yield strength Mg-Ni-Ti-Al quaternary alloy of the present embodiment, the chemical composition of described alloy is expressed as Mg by atomic ratio 1.9 NiTiAl 0.1 , the microstructure of the alloy is based on Mg 2 Ni is the parent phase, and a large number of nanoscale strengthening phases are dispersed in the alloy, and the strengthening phase is a B2-NiTi intermetallic compound; wherein: the density of the alloy is 3.16g / cm 3 , the average specific yield strength is 326MPa·cm 3 / g, the average hardness of the alloy is 3.12GPa.

[0067] The low-density, ultra-high specific yield strength Mg-Ni-Ti-Al quaternary alloy described above in this embodiment is prepared by the following method, and the steps are as follows:

[0068] (1) Material preparation:

[0069] The high-purity (above 3.5N) Mg, Ni, Ti and Al metal powders used have a uniform particle size and should be less than 48 μm (300 mesh). The process control agent i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com