Product inner side revolving laser marking device and marking method

A technology of laser marking and laser marking head, which is applied in the field of rotary laser marking devices inside the product, which can solve the problems of inability to complete marking with uniform depth and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

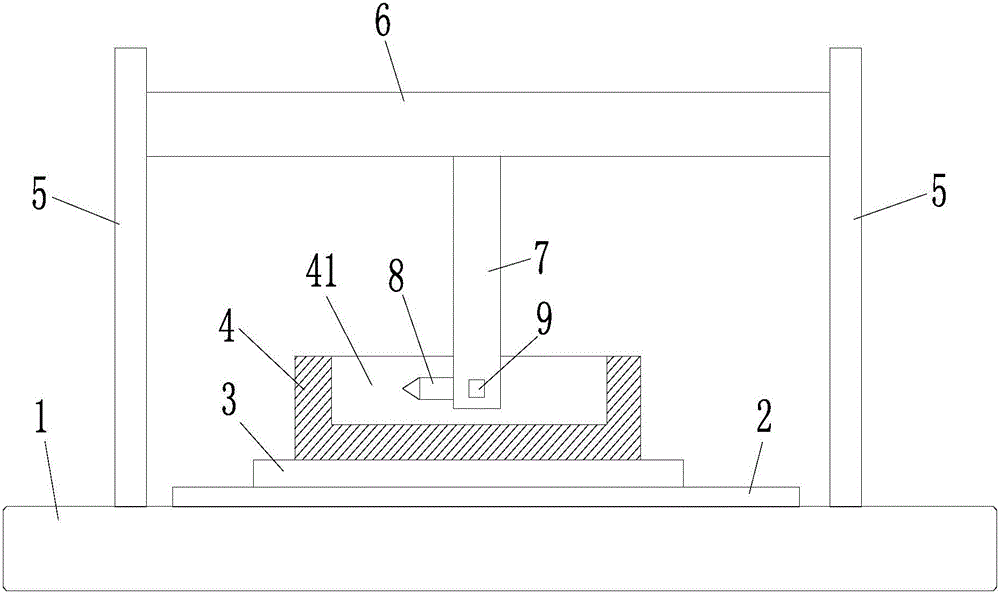

[0016] Embodiment: A rotary laser marking device inside a product, including a body 1, a workbench 2 arranged on the body 1, a laser marking head 8 connected to the body 1 through a bracket, and the workbench 2 can be moved forward and backward. Mobilely arranged on the fuselage 1, the workbench 2 is rotatably connected with a fixture 3 for clamping the product 4 to be marked. Bracket 5, the beam 6 that is connected to the two vertical brackets 5 at both ends can move up and down, the slider 7 that can move left and right along the beam 6 and is connected to the beam 6, and the laser marking head 8 is fixedly connected to the slider. on block 7.

[0017] The rotation axis of the above-mentioned clamp 3 is arranged along the vertical direction.

[0018] The rotary laser marking device inside the product also includes a plurality of servo motors that control the movement of the workbench 2, the vertical support 5, the beam 6 and the slider 7 and the rotation of the fixture 3 re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com