Laser marking device with distance measurement function and laser marking method

A technology of laser marking and ranging device, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of uneven laser marking depth on product surface, inability to product uniformity, laser marking and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

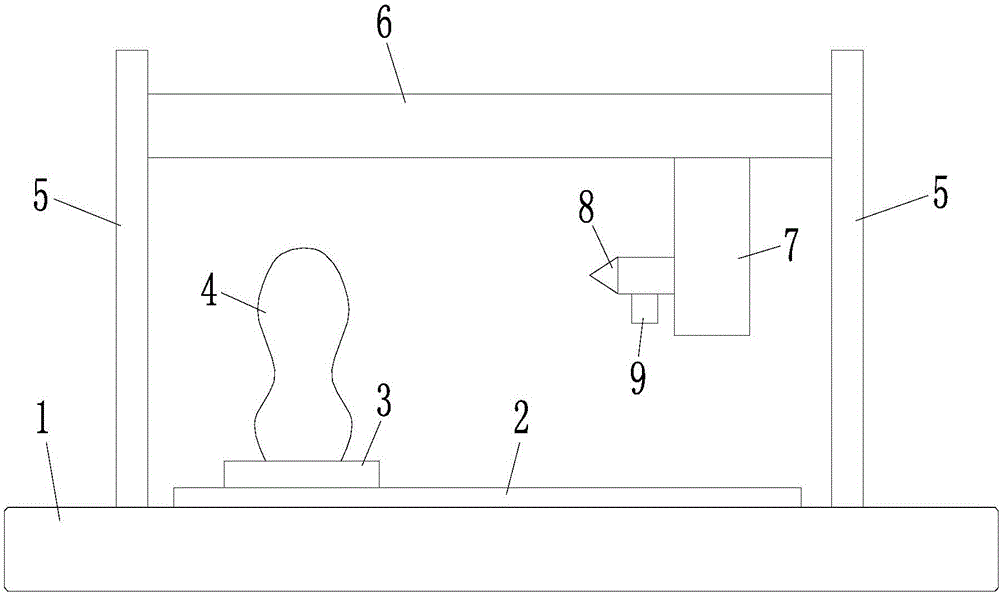

[0014] Embodiment: a distance-measuring laser marking device, comprising a frame 1, a workbench 2 fixedly connected to the frame 1, a fixture 3 arranged on the workbench 2 and used to clamp a product 4 to be marked, The laser marking head 8 that can be moved up and down, left and right, and forward and backward on the frame 1, the transmission mechanism that drives the laser marking head 8 to move, is fixedly connected with the laser marking head 8, and is used to detect the laser marking head 8 and the laser marking head 8. The distance measuring device 9 that marks the distance between the products 4, is connected with the signal of the distance measuring device 9 and controls the controller that the laser marking head 8 moves by the distance measured by the distance measuring device 9 (not shown in the accompanying drawings) ).

[0015] Specifically, the distance measuring device 9 is a distance sensor.

[0016] In a more preferred embodiment, the jig 3 is rotatably arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com