Mounting and dismounting device, mounting method and dismounting method of bearing withdrawal sleeve

An installation method and a technology for withdrawing sleeves, which are applied in hand-held tools and manufacturing tools, can solve problems such as high cost, small operating space, and inability to install and disassemble bearing withdrawal sleeves.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

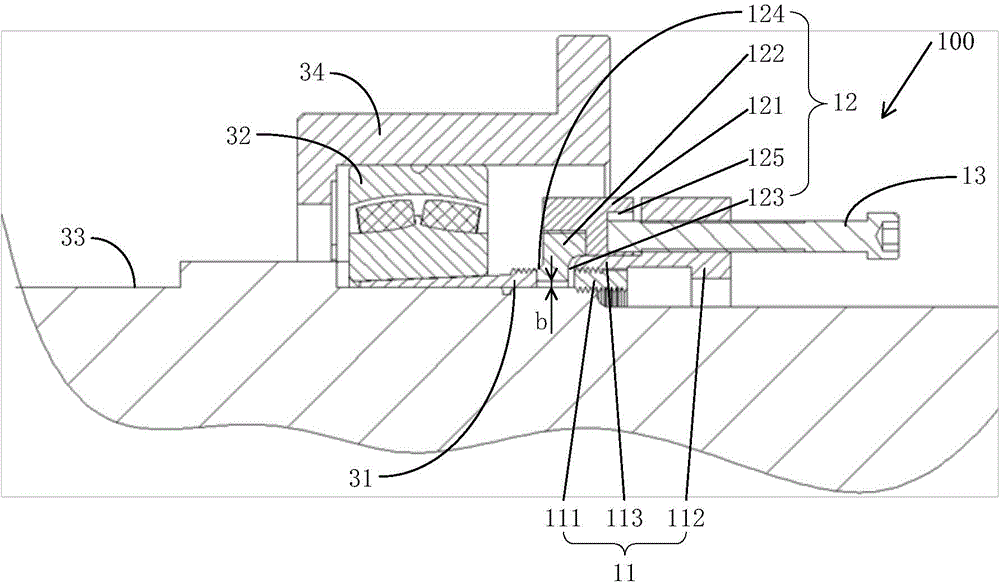

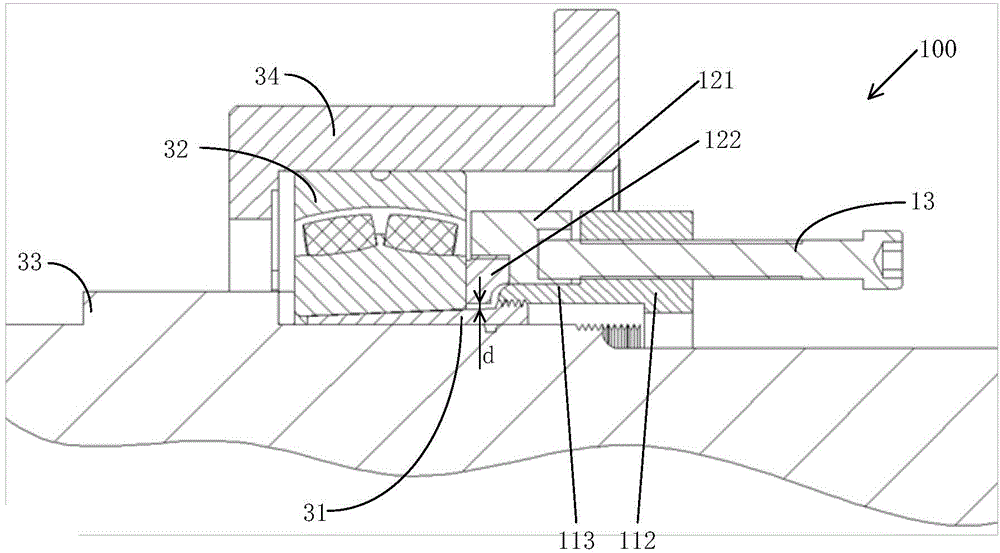

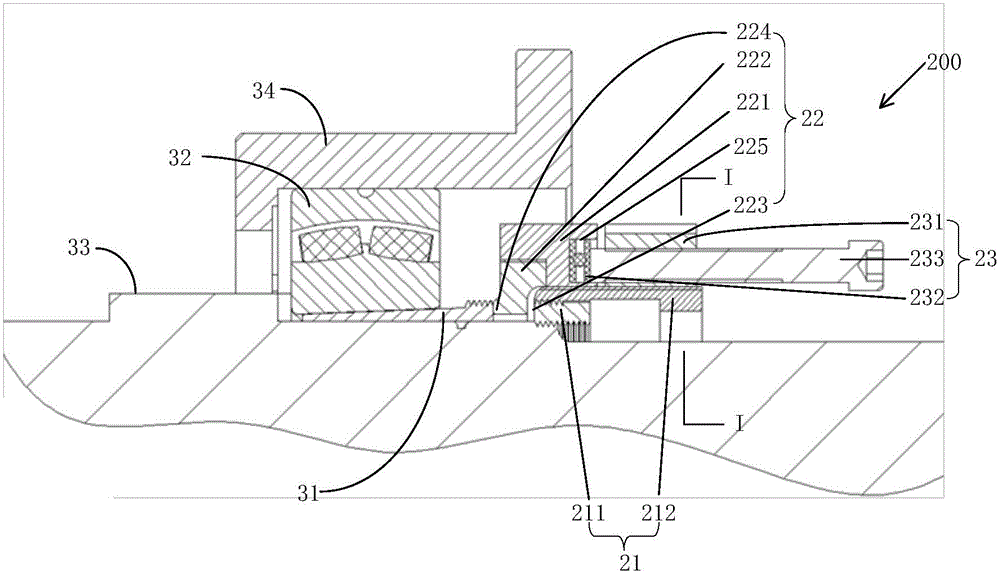

[0029] refer to figure 1 and figure 2 , figure 1 It is a schematic cross-sectional view of the first embodiment of the assembly and disassembly device for the bearing withdrawal sleeve of the present invention to realize the installation of the bearing withdrawal sleeve, figure 2 It is a schematic cross-sectional view of the first embodiment of the assembly and disassembly device for the bearing withdrawal sleeve of the present invention to realize the disassembly of the bearing withdrawal sleeve.

[0030] figure 1 and figure 2 Indicates that the same assembly and disassembly device is used to realize the installation and disassembly of the bearing withdrawal sleeve. Thus, in figure 1 and figure 2 The reference numbers for the same parts are the same. Among them, the present embodiment provides an assembly and disassembly device 100 to realize the assembly and disassembly of the bearing withdrawal sleeve 31, specifically, push or pull the bearing withdrawal sleeve 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com