Injection method capable of increasing steam huff and puff recovery ratio of heavy oil well

A recovery factor and oil well technology, which is applied in the injection field of improving the steam huff and puff recovery factor of heavy oil wells, can solve the problems of rising oil-water ratio, worse economic benefit, and lower oil-steam ratio, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

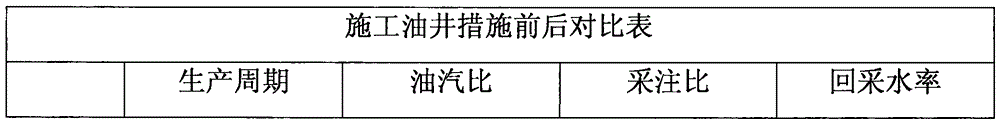

[0021] HD9008 well

[0022] Construction preparation

[0023] Preparation of wellbore, wellhead and construction string

[0024] Wellbore: The well condition is intact, and there is no fallout in the well;

[0025] Wellhead: The wellhead flange screws are complete, the wellhead valve switch is flexible, no puncture or leakage, the pressure gauge is intact, and the wellhead is intact;

[0026] Construction team: operation team;

[0027] Operating equipment:

[0028] 1 400 type pump truck;

[0029] One tank car, the tank car is cleaned before pulling the liquid, there must be no oil stains and other residual liquids, one liquid distribution tank;

[0030] The connecting hard pipeline between the pump truck and the wellhead, etc.

[0031] materials, drugs

[0032] serial number

name

unit

quantity

1

Accompanying injection

m 3

4.4

2

Hot water above 50°C

m 3

13.6

[0033] Construction steps and technical requ...

Embodiment 2

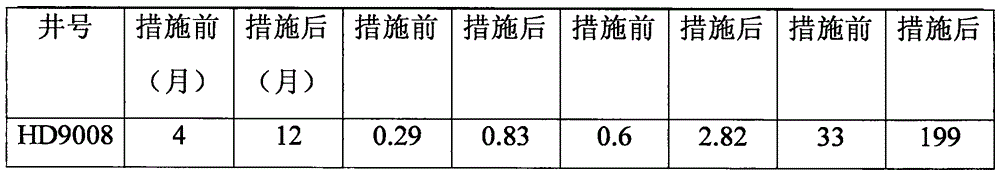

[0045] HD9009 well

[0046] Construction preparation

[0047] Preparation of wellbore, wellhead and construction string

[0048] Wellbore: The well condition is intact, and there is no fallout in the well;

[0049] Wellhead: The wellhead flange screws are complete, the wellhead valve switch is flexible, no puncture or leakage, the pressure gauge is intact, and the wellhead is intact;

[0050] Construction team: operation team;

[0051] Operating equipment:

[0052] 1 400 type pump truck;

[0053] One tank car, the tank car is cleaned before pulling the liquid, there must be no oil stains and other residual liquids, one liquid distribution tank;

[0054]The connecting hard pipeline between the pump truck and the wellhead, etc.

[0055] materials, drugs

[0056] serial number

name

unit

quantity

1

Accompanying injection

m 3

4

2

Hot water above 50°C

m 3

11

[0057] Construction steps and technical requireme...

Embodiment 3

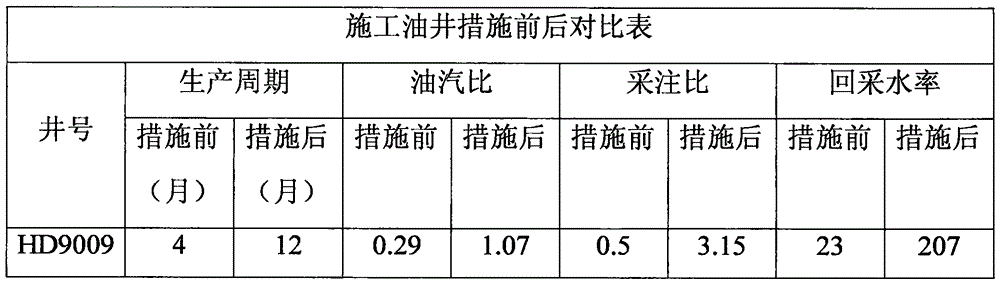

[0067] HD91394 well

[0068] Construction preparation

[0069] Preparation of wellbore, wellhead and construction string

[0070] Wellbore: The well condition is intact, and there is no fallout in the well;

[0071] Wellhead: The wellhead flange screws are complete, the wellhead valve switch is flexible, no puncture or leakage, the pressure gauge is intact, and the wellhead is intact;

[0072] Construction team: operation team;

[0073] Operating equipment:

[0074] 1 400 type pump truck;

[0075] One tank car, the tank car is cleaned before pulling the liquid, there must be no oil stains and other residual liquids, one liquid distribution tank;

[0076] The connecting hard pipeline between the pump truck and the wellhead, etc.

[0077] materials, drugs

[0078] serial number

name

unit

quantity

1

Accompanying injection

m 3

3.5

2

Hot water above 50°C

m 3

11.5

[0079] Construction steps and technical req...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com