Method for rapidly withdrawing fully mechanized coal mining face device of steep seam

A fully-mechanized mining face and steeply inclined technology, which is applied to mining equipment, earthwork drilling, and mineral-carrying trucks, etc., can solve the problems of insecure equipment for workers on the face, difficulty in replacing the face, and problems with coal and rock mass slabs. Problems such as roof fall, to achieve the effect of shortening the retraction time of the equipment, little deformation, and short retraction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

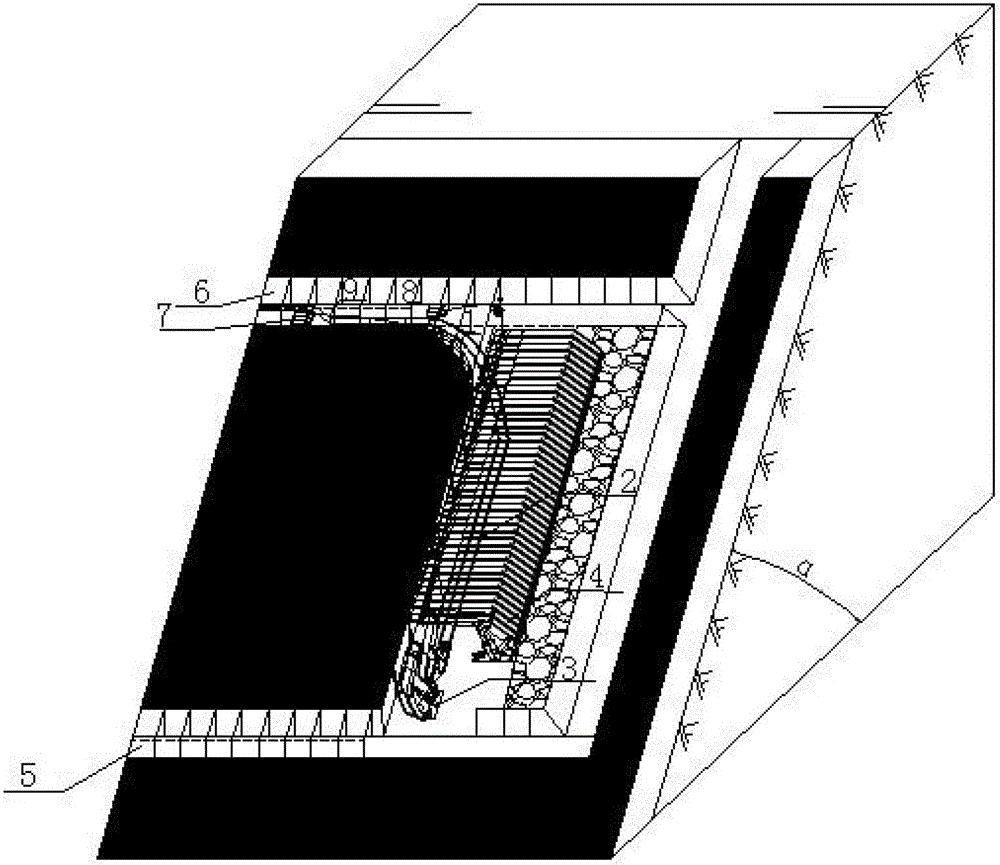

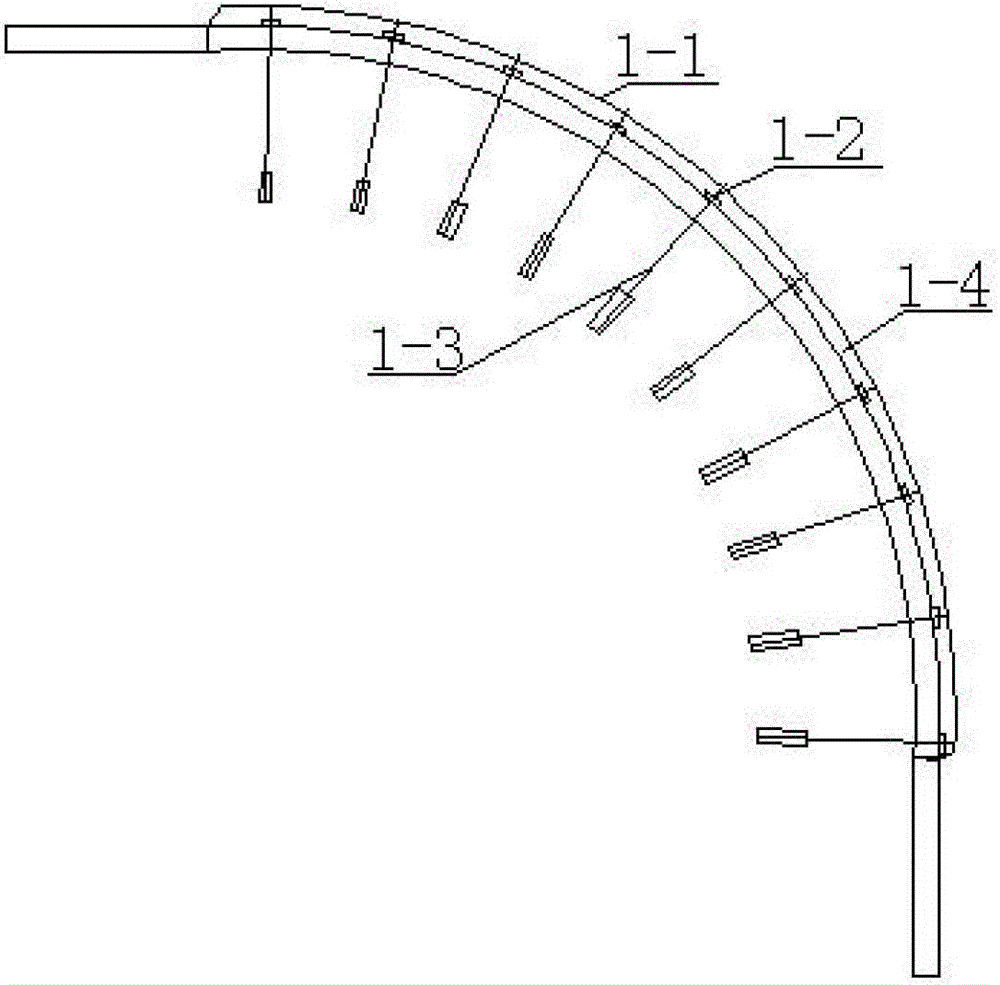

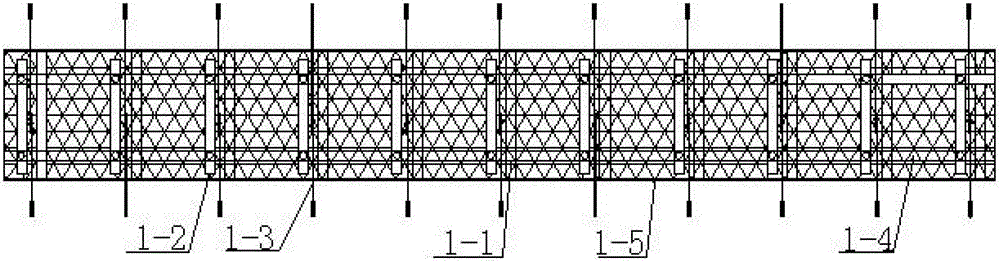

[0028] Such as figure 1 As shown, when the tip back mining on the steeply inclined fully mechanized mining face with an inclination angle α greater than 45° reaches the production stop line, a quarter-circle retraction roadway 1 is excavated along the head end of the working face; 6 Install a column return winch as the main winch 7 of the recovery fully mechanized mining equipment, and install an auxiliary winch 8 in cooperation with the pulley for auxiliary lifting in the return air level road ahead of the working face. The air return alley main winch 7 and the air return alley auxiliary winch 8 in the air return alley 6 of the working face are all fixed on the concrete base with bolts, and are reinforced with ground anchors, and set up a firm column. Lay the rail 9 in the return air level roadway as usual; use the I-beam 2-1 in the coal mining face to la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com