A kind of preparation method of iron-toed shoes

A technology of iron-toed shoes and iron-toed shoes, which is applied in footwear, applications, clothing, etc., can solve the problems of high mechanical strength of iron-toed shoes, achieve the effects of not being easy to age and crack, good elasticity, and enhanced tensile and elastic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

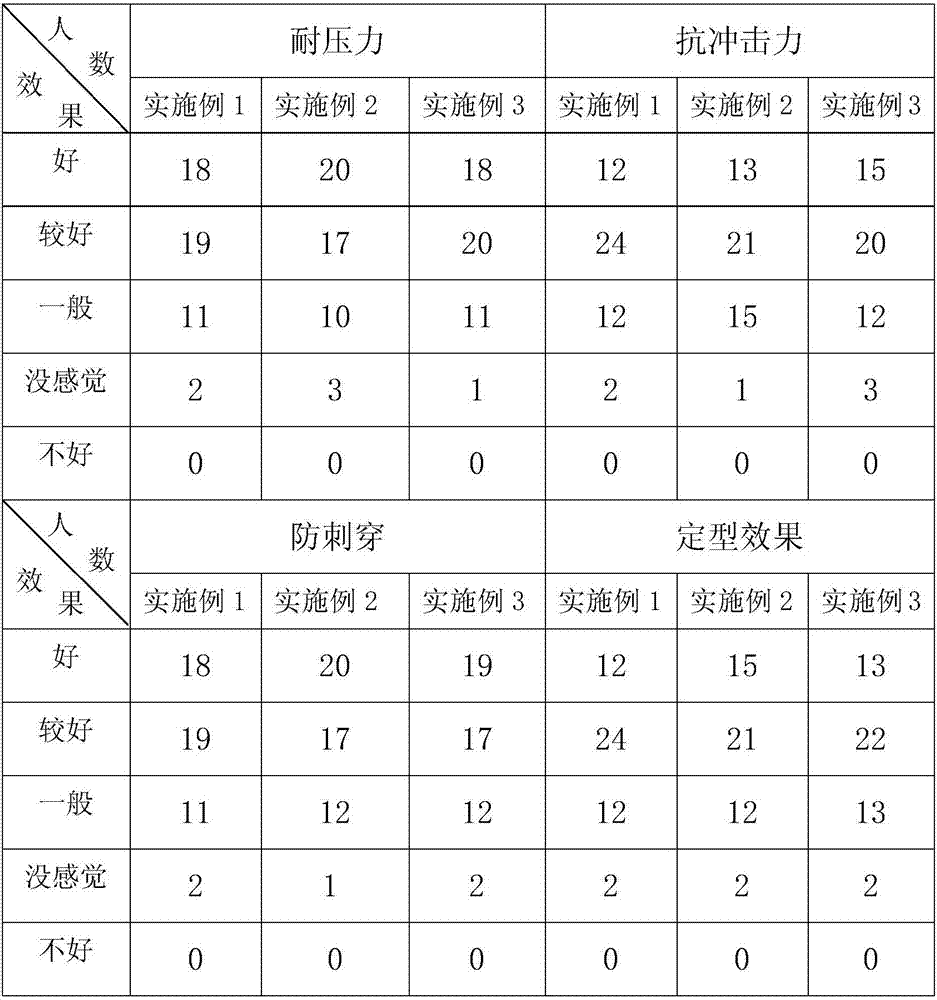

Examples

Embodiment 1

[0035] An iron-toed shoe, which is manufactured by hot-melting rubber materials for the iron-toed shoe and injecting them into a mold, making them into a large shoe body, a large toe cap, a rear bead, a rear lining, a rear cover, and a reinforcing member, and then combining them. Processing into iron-toed shoes, the preparation steps are as follows:

[0036] a. Take the sock and the last that matches the sock, put the last into the sock, and then fix the sock at the end of the last; draw at least two on the sock with the same height as the shoe body The front and rear height points of the same height, and then draw the connecting line between the height points according to the height points;

[0037] b. Take the iron head U-shaped reinforcement member, and brush the adhesive on the iron head U-shaped reinforcement member, then place the iron head U-shaped reinforcement member in a 60°C oven for 2.5 minutes, and then put the iron head The U-shaped reinforcing member is attache...

Embodiment 2

[0055] An iron-toed shoe, which is manufactured by hot-melting rubber materials for the iron-toed shoe and injecting them into a mold, making them into a large shoe body, a large toe cap, a rear bead, a rear lining, a rear cover, and a reinforcing member, and then combining them. Processing into iron-toed shoes, the preparation steps are as follows:

[0056] a. Take the sock and the last that matches the sock, put the last into the sock, and then fix the sock at the end of the last; draw at least two on the sock with the same height as the shoe body The front and rear height points of the same height, and then draw the connecting line between the height points according to the height points;

[0057] b. Take the iron head U-shaped reinforcement member, and brush the adhesive on the iron head U-shaped reinforcement member, then place the iron head U-shaped reinforcement member in an oven at 62°C for 2.5 minutes, and then put the iron head The U-shaped reinforcing member is att...

Embodiment 3

[0075] An iron-toed shoe, which is manufactured by hot-melting rubber materials for the iron-toed shoe and injecting them into a mold, making them into a large shoe body, a large toe cap, a rear bead, a rear lining, a rear cover, and a reinforcing member, and then combining them. Processing into iron-toed shoes, the preparation steps are as follows:

[0076]a. Take the sock and the last that matches the sock, put the last into the sock, and then fix the sock at the end of the last; draw at least two on the sock with the same height as the shoe body The front and rear height points of the same height, and then draw the connecting line between the height points according to the height points;

[0077] b. Take the iron head U-shaped reinforcement member, and brush the adhesive on the iron head U-shaped reinforcement member, then place the iron head U-shaped reinforcement member in an oven at 65°C for 2.5 minutes, and then put the iron head The U-shaped reinforcing member is atta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com