Fluid spraying device of metal materials

A metal material, spraying device technology, applied in the direction of spraying device, etc., can solve problems such as high cost and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

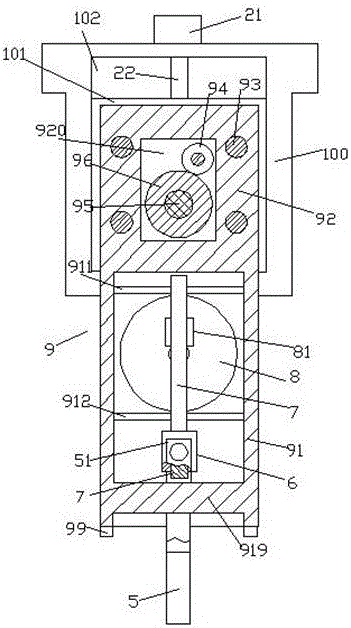

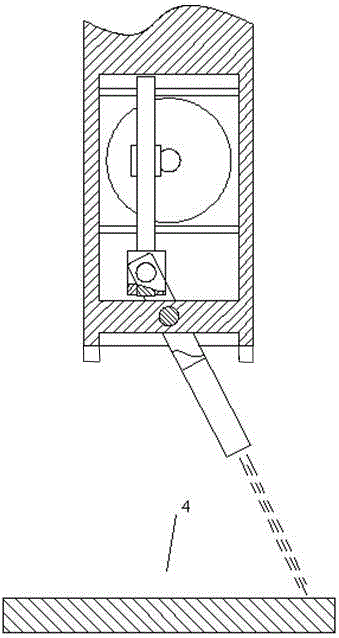

[0009] Combine below Figure 1-2 The present invention will be described in detail.

[0010] The fluid spraying device of metal material according to the embodiment of the present invention is used for spraying fluid to the object 4 to be sprayed, and comprises the housing 9 that is made of upper supporting part 92 and lower driving accommodating part 91, and described upper supporting part 92 is passed and adjusted A plurality of guide rods 93 fixedly connected to the base 101 are slidably matched to realize support, and the adjustment base 101 is slidably matched with the chute 102 arranged in the frame 100, and an adjustable adjustment base is installed on the upper end of the frame 100 101 height adjustment motor 21, the symmetry axis of the adjustment base 101 is threaded with a lifting screw 22, the lower end of the lifting screw 22 is rotatably installed on the lower end of the frame 100, and the upper end of the lifting screw 22 runs through the frame 100 And it is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com