Device and method for handling, mounting or demounting components of wind turbine

A technology of wind power generation equipment and components, which is applied in the field of rotor blades and/or nacelle devices, and can solve problems such as difficult rotor blade adjustment assembly positions, invisible assembly states, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

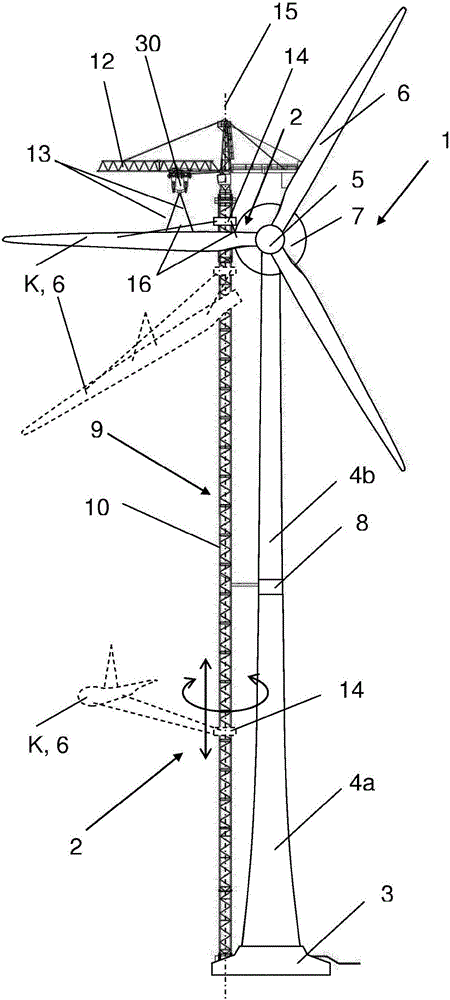

[0031] figure 1 The device and method for operating, assembling or disassembling components of a wind power plant and a wind power plant 1 under construction are shown in a schematic overview. Here, the wind power plant 1 consists of a base 3, a tower 4 and different functional units (of which a hub 5 with rotor blades 6 and a nacelle 7 can now be seen) in a known manner. According to this figure, the tower body 4 is here divided into two segments 4 a, 4 b, which are connected to each other by an intermediate piece 8. In principle, the tower body 4 can be composed of cast-in-place concrete, prefabricated concrete or steel, or be built with a mixed structure of different materials. Preferably, the lower section 4a of the tower body is composed of a concrete prefabricated part, which supports each other between the middle part 8 and the base 3, and the steel as the second section 4b is supported on the lower section. For the mast, the second section can be one piece or can also ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com