Expansion liner hanger with hydraulic double drop mechanism

A technology of liner hanger and hands-off mechanism, which is applied in wellbore/well parts, earthwork drilling and production, etc. It can solve problems such as insufficient expansion force and safety risks, and achieve convenience in downhole operations, saving man-hours, sealing and sand prevention good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

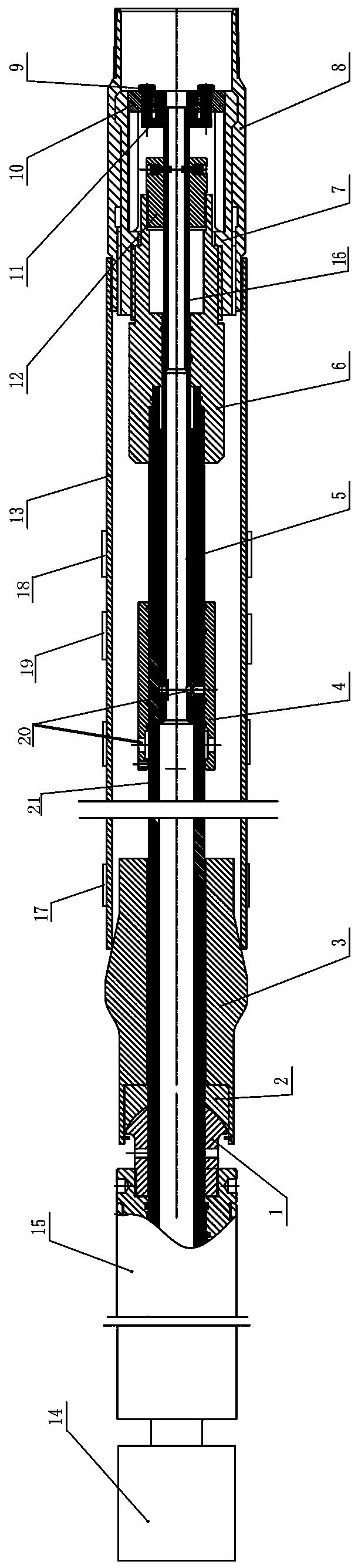

[0013] A hydraulic double drop-hand mechanism expansion liner hanger, such as figure 1 As shown, it includes the expansion base pipe 13, the expansion cone 3, and the hydraulic cylinder 15 that are sequentially fitted on the inner pipe string 21. The overall structure of the expansion cone 3 has been disclosed in another utility model patent ZL201320724659.2 of the applicant. , which will not be repeated here. The top of the expansion cone 3 is provided with a ball socket 2 and a ball head 1 assembly set on the inner pipe string 21. The upper end of the ball head 1 is connected with the lower end of the hydraulic cylinder 15 through threads. A liquid injection hole is arranged on the top surface of the upper end liquid cylinder, and the upper variable button joint 14 is connected to the upper end of the inner pipe string.

[0014] The lower end of the expansion base pipe 13 below the expansion cone 3 is connected with the collet 8, and the collet 7 is set inside the collet 8,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com