A sailboat rope coating and hot drafting workbench

A hot drafting and workbench technology is applied in the field of sailing rope crafting equipment, which can solve the problems of reducing the static elongation rate, failing to improve the strength-diameter ratio of the sailing rope, and the equipment site being dirty, etc. The effect that the environment is clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

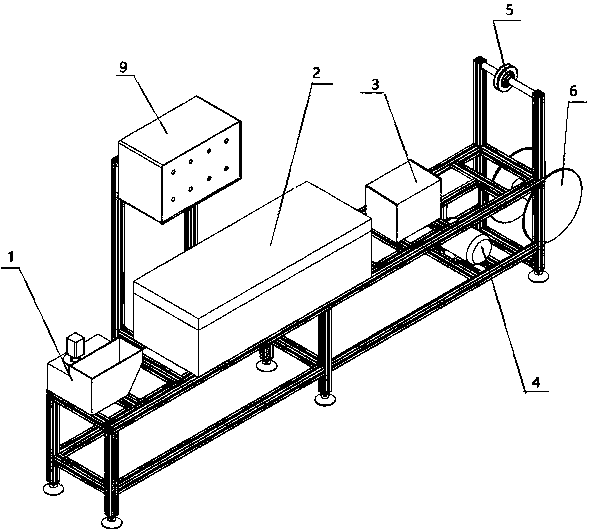

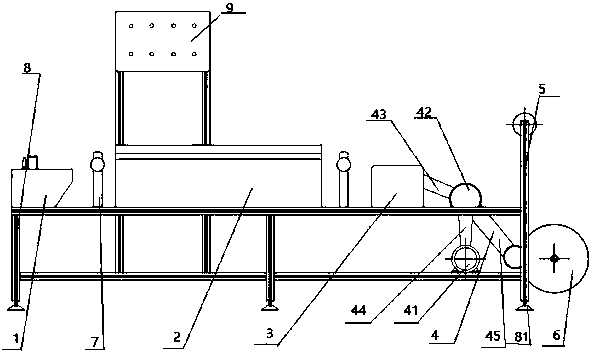

[0025] Such as figure 1 and 2 As shown, the sailboat rope coating and thermal drafting workbench includes a bracket 8, and the coating device 1, oven device 2, thermal drafting device 3, power transmission device 4, row A wire device 5 and a winding device 6, a wire passing roller device 7 is respectively arranged between the coating device 1, the oven device 2, and the thermal drafting device 3, and the thermal drafting device 3 and the winding device 6 are respectively connected with the The power transmission device 4 is connected, the cable arrangement device 5 and the winding device 6 are respectively arranged on the upper part and the lower part of one side of the support 8, and the upper part of the oven device 2 is provided with a control cabinet 9 to adjust the parameters of each device.

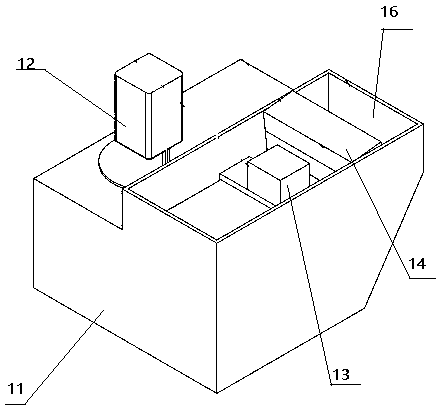

[0026] Such as image 3 and 4 As shown, the coating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com