Spelunking rope manufacturing process

A production process and rope technology, applied in the direction of wear-resistant fibers, braids, fiber types, etc., can solve the problems of poor aging resistance and waterproof performance, inaccurate elongation positioning, and no thermal drafting and shaping, and achieve waterproofing. Good performance, low static elongation, good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A method for making a caving rope, the steps of which are:

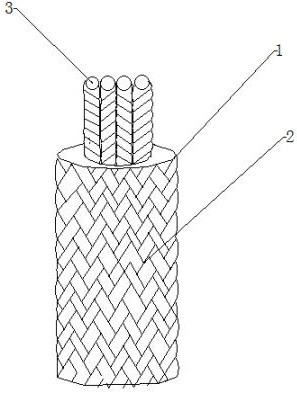

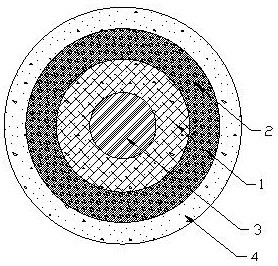

[0054] 1) Material selection: choose nylon, polyester or aramid fiber filaments to make the rope sheath 1, and choose nylon fiber filaments to make the rope core 3;

[0055] 2) Rope sheath twisting: the specification is 3*840D rope sheath-1, the twist is set to 120 twists / m, twisted by the ring twisting machine and combined into one strand, and the width specification is 0.3mm rope sheath-22 No twisting spare;

[0056] 3) Preparation of coating finishing solution: prepare coating finishing solution, the ratio of water and ICOATS-REPEL in the coating is: 20%: 80% or the ratio of water and HUNTSMAN-PHOBOL-NB-NH is: 30%: 70% in Stir in the container with a magnetic stirrer until uniform;

[0057] 4) Rope core initial twist: take (6 pieces) * (840D) rope core 3 to twist, and the initial twist twist is 220 twists / m;

[0058] 5) Rope core retwisting: after the initial twisting, take 3*(6 pieces)*(840D) rope core ...

Embodiment 2

[0064] A method for making a caving rope, the steps of which are:

[0065] 1) Material selection: choose nylon, polyester or aramid fiber filaments to make the rope sheath 1, and choose nylon fiber filaments to make the rope core 3;

[0066] 2) Rope sheath twisting: the specification is 5*1260D rope sheath-1, the twist is set to 100 twists / m, the twisting is combined into one strand through the ring twisting machine, and the width specification is 4mm rope sheath-22 Twisting spare;

[0067] 3) Preparation of coating finishing solution: prepare the coating finishing solution, the ratio of water and ICOATS-REPEL in the coating is: 30%:70% or the ratio of water and HUNTSMAN-PHOBOL-NB-NH is: 50%:50% in Stir in the container with a magnetic stirrer until uniform;

[0068] 4) Rope core initial twist: take (12 pieces) * (840D) rope core 3 to twist, and the initial twist twist is 150 twists / m;

[0069] 5) Rope core re-twisting: After the initial twisting, take 3*(12)*(840D) rope co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

| force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com