A double-station linkage positioning device

A positioning device and double-station technology, applied in the direction of workpiece clamping devices, auxiliary devices, manufacturing tools, etc., can solve the problems of difficult clamping and positioning, difficult to take out micro parts, easy to be damaged, etc., to save time and improve Efficiency, fast retrieving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

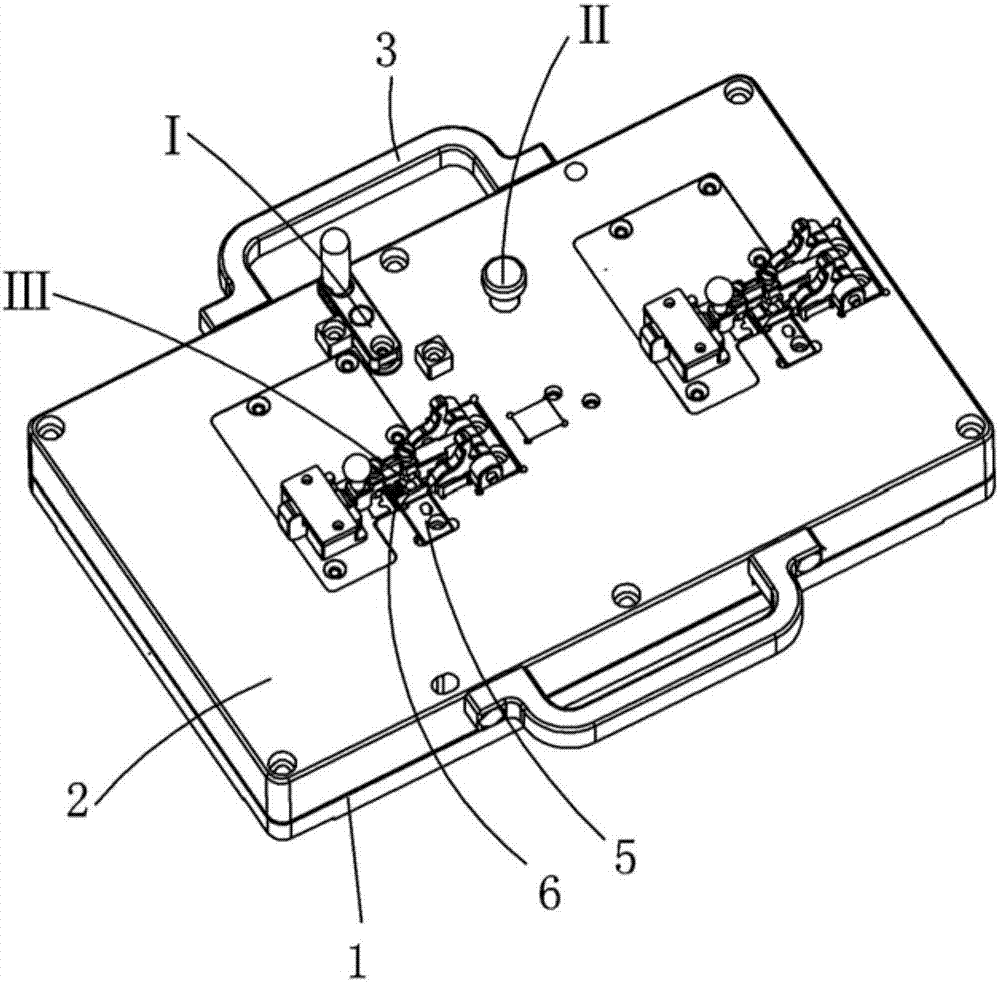

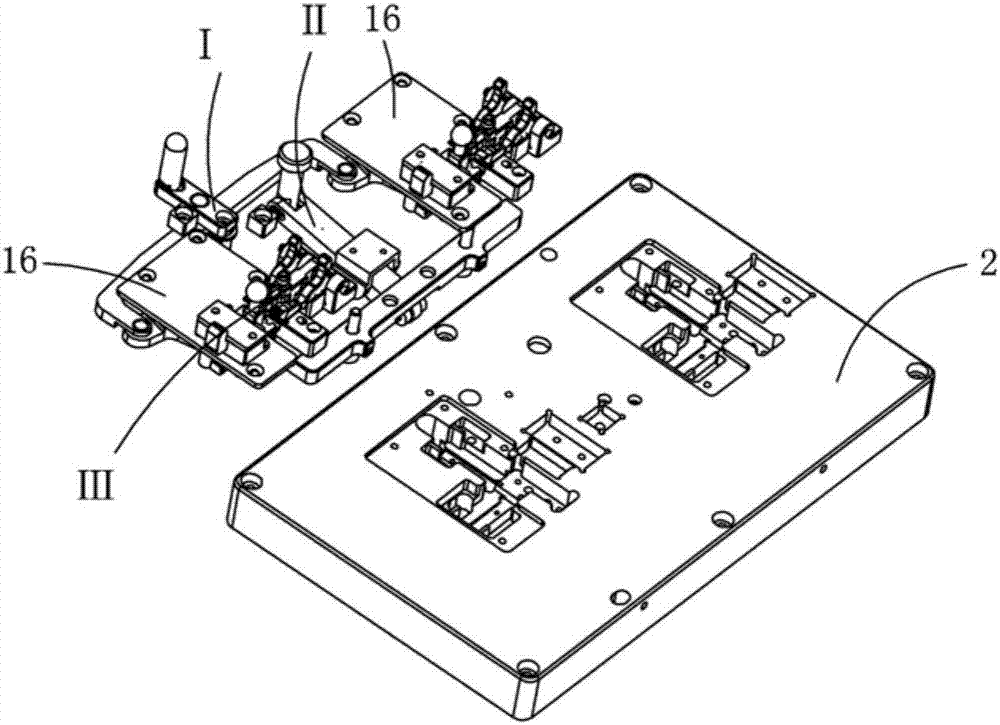

[0033] Examples, see attached Figure 1-14 , A dual-station linkage positioning device, this device works with the quick reclaiming component and the pressing component to realize the positioning of two products at a time; it can realize the rapid retrieving and solve the problem of too small and difficult to take out of the micro parts; Equipped with compression components, can compress micro parts and products to ensure stability.

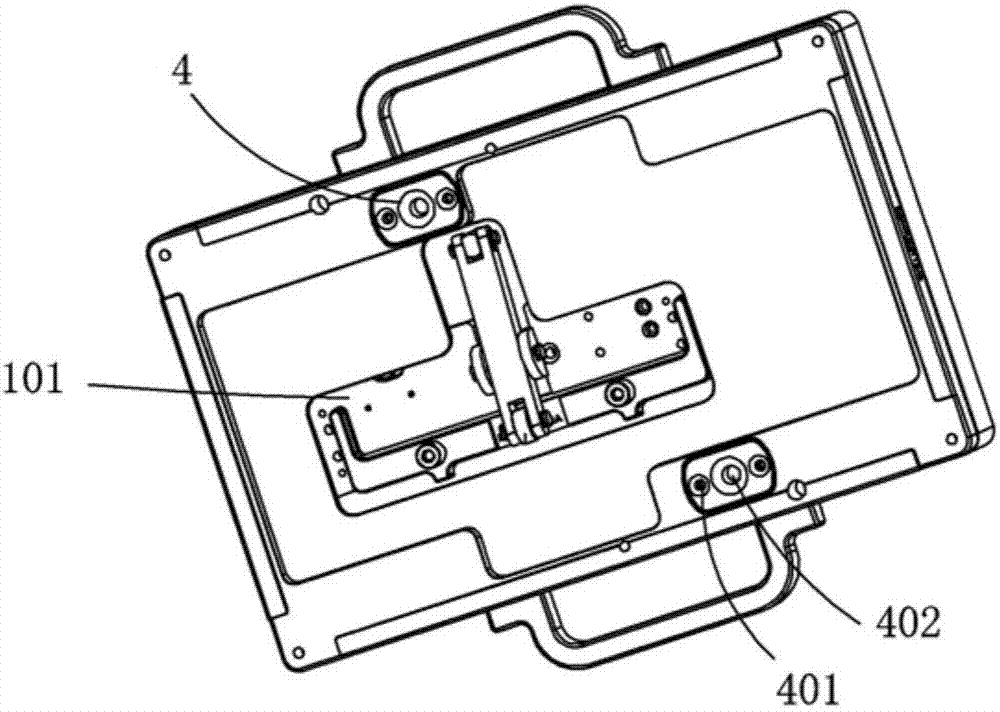

[0034] The device includes a lower base plate 1 and an upper box body 2 installed on the upper part of the lower base plate. The lower base plate has a flat structure. The cross-sectional size of the lower base plate is the same as that of the upper box body. The upper box body is screwed and fixed on the lower base plate. A through groove 101 is provided, and the reclaiming connecting rod and the ejector rod mounting seat of the quick reclaiming assembly are respectively located at the through groove positions. The front and rear sides of the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com