A terminal block

A technology of terminal block and shrapnel, applied in the direction of contact parts, clamping/spring connection, etc., can solve the problems of terminal losing wiring function, easy to fall off and damage, etc., and achieve the effect of optimizing structure size and reducing structure width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

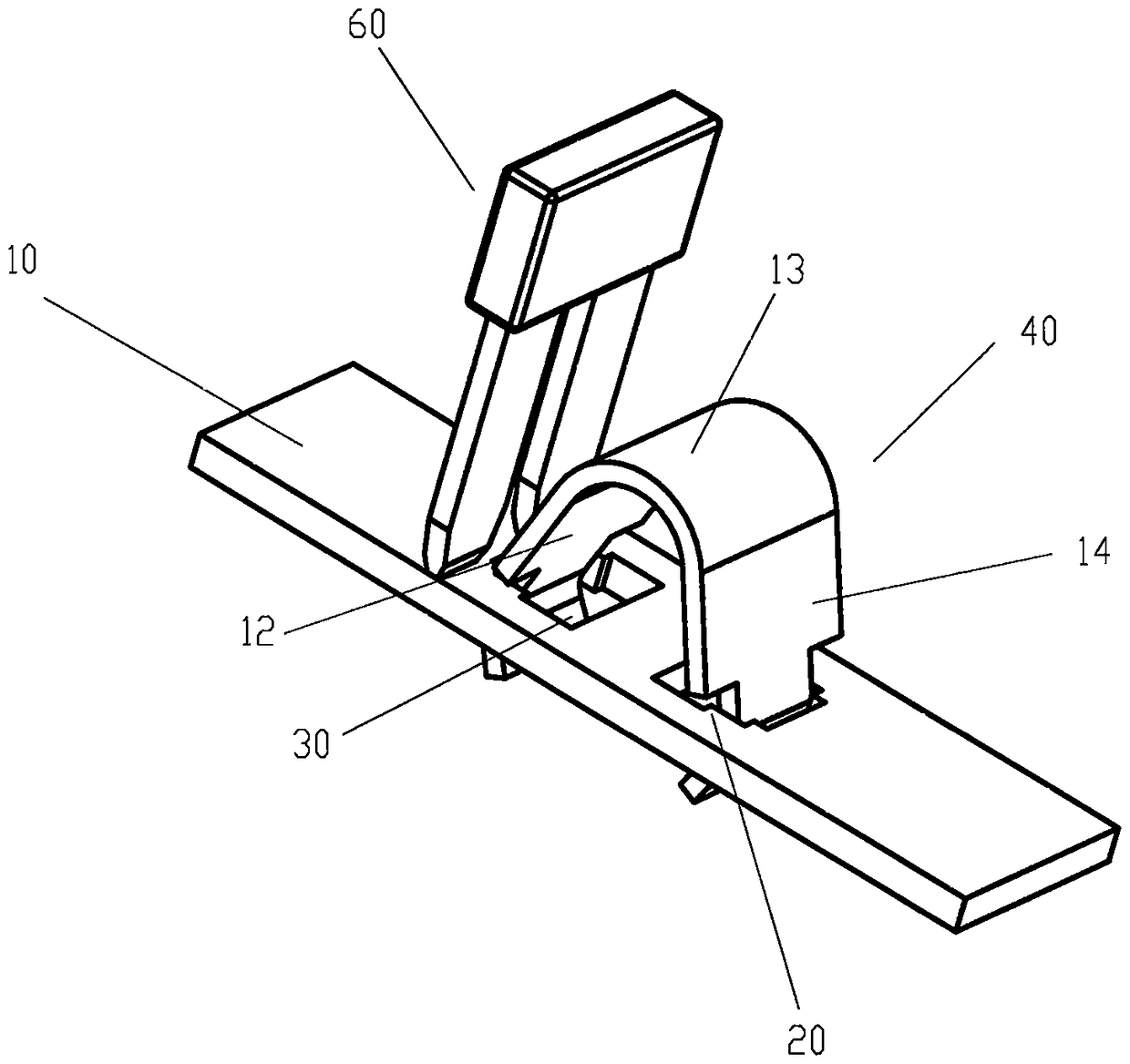

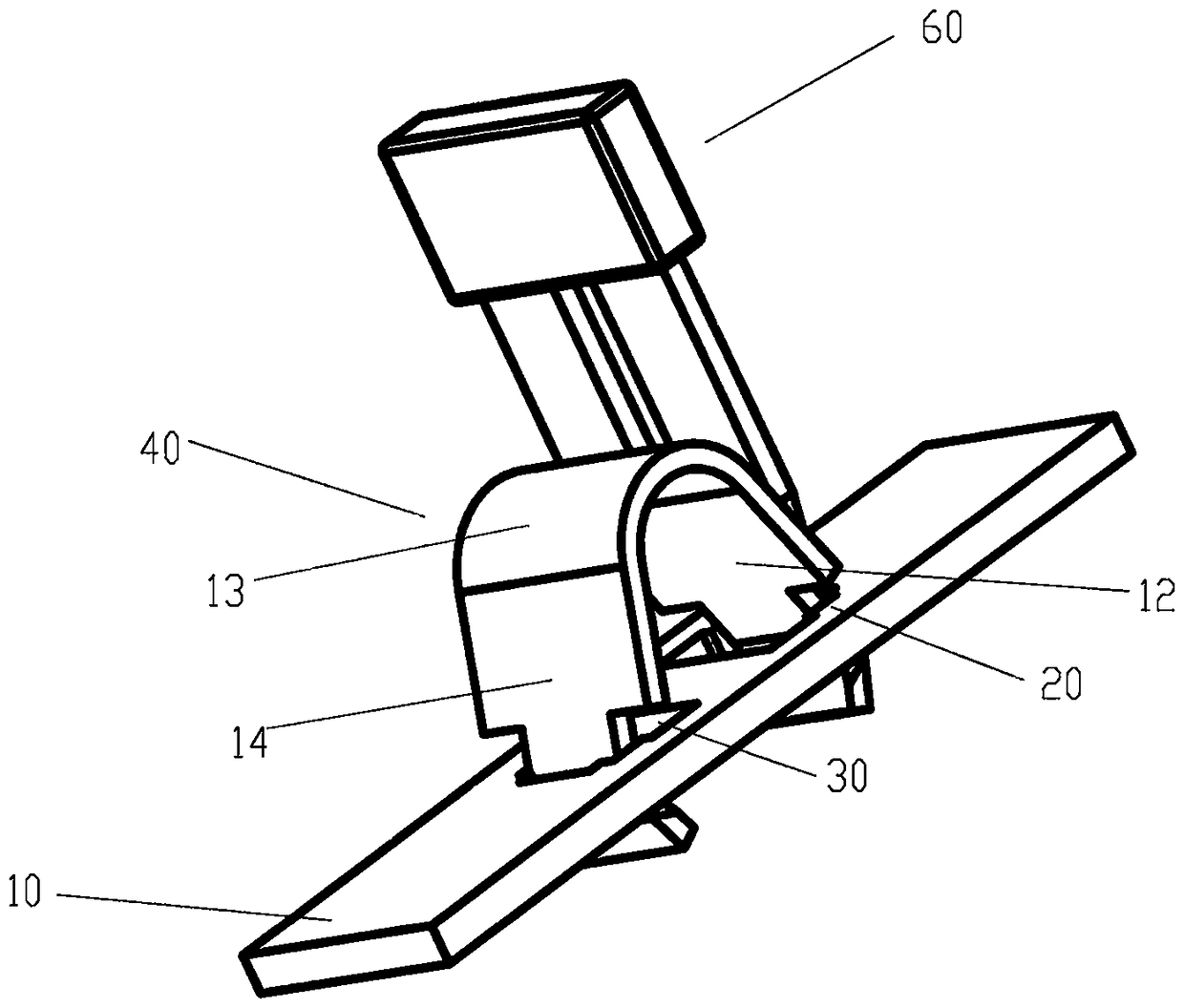

[0025] Such as Figure 1-4 As shown, the present invention provides a terminal block. The main body structure 10 of the metal plate of the terminal block is roughly a rectangular hexahedron, and at least one groove portion 30 is arranged on it. Preferably, the groove portion 30 penetrates through the main body of the metal plate. Through hole of structure 10 . Moreover, the corner of at least one side wall 20 of the groove portion 30 is formed in a stepped shape.

[0026] The terminal block also has an elastic piece 40, the elastic piece has an obvious U-shaped bending portion 13, and the bending portion 13 has an obvious bending radius, and when it is in a rest position, it can make the first arm portion 12 and the second arm portion 12 of the elastic piece The two arm parts 14 have at least elasticity to be far away from each other.

[0027] Preferably, near the middle of the metal plate main structure 10, two mirror-symmetric grooves 30 are arranged along the longitudinal...

Embodiment 2

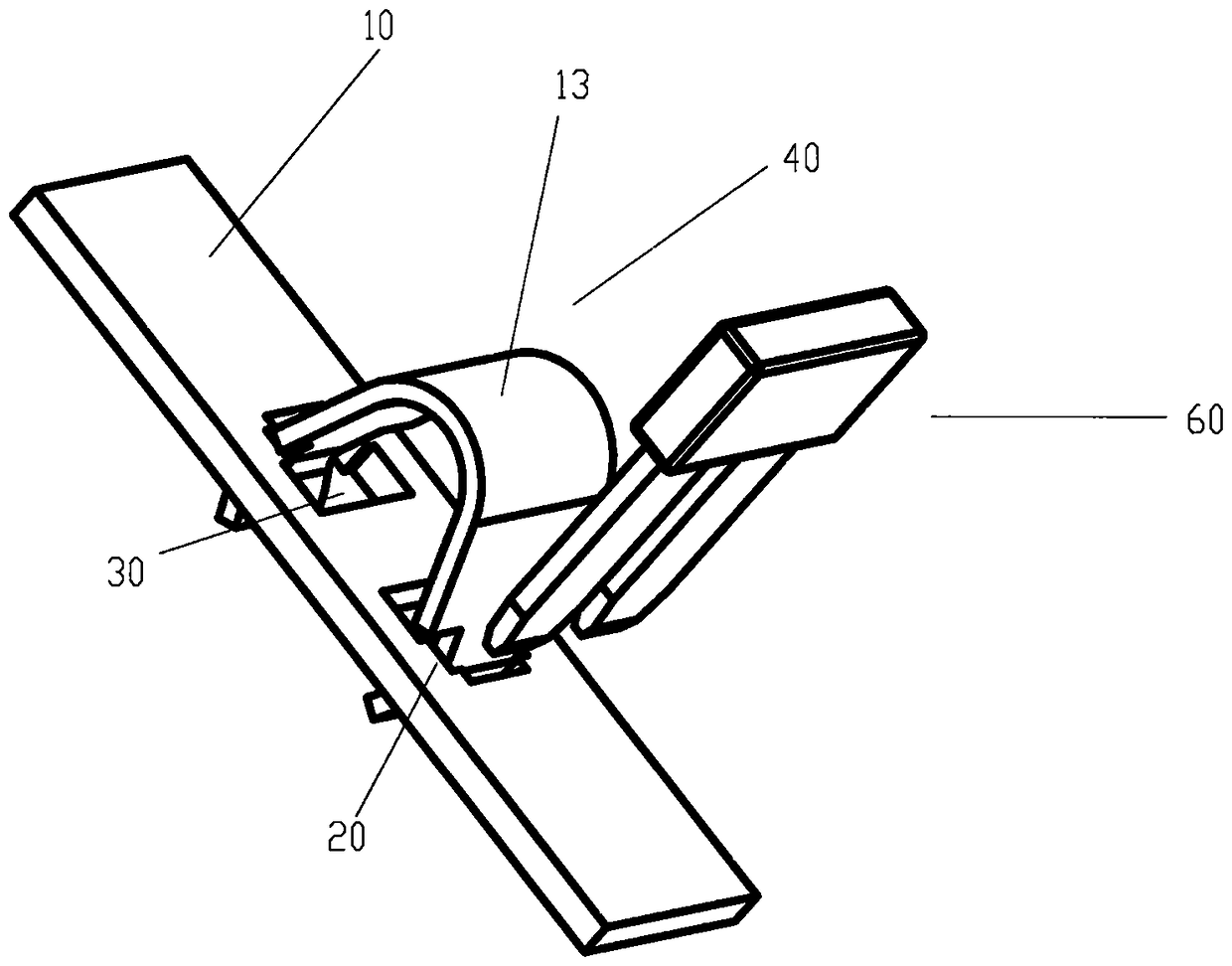

[0033] Unlike the elastic piece in Embodiment 1, which has an obvious bending radius, the bending portion 13 of the elastic piece is in the extension of the first arm portion 12 and the second arm portion 14, gradually making the first arm portion 12 and the second arm portion 14 The ends of the two arm parts 14 abut against each other, so that the structural width of the elastic piece in the clamping direction can be reduced, thereby optimizing the structural size of the entire terminal.

[0034] Preferably, the ends of the first arm portion 12 and the second arm portion 14 of the elastic piece 40 are folded and abutted together at the bending portion 13, such folded abutment passes through making the first arm portion 12 and the second arm portion 14 of the elastic piece 40 The arm portion 14 is bent by 180°, and the preferred elastic sheet is made of high-quality spring steel sheet, which is folded during the deformation process.

[0035] Optionally, the first arm 12 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com