Power supply circuit and its operation method for automatically matching the number of parallel groups of loads

A technology of automatic matching and power supply circuits, applied in the direction of electrical components, adjusting electric variables, output power conversion devices, etc., can solve the problems of reducing production costs, without mentioning the number of parallel groups of automatic matching loads, etc., to achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to fully understand the technical content of the present invention, the technical solution of the present invention will be further introduced and illustrated below in conjunction with specific embodiments, but it is not limited thereto.

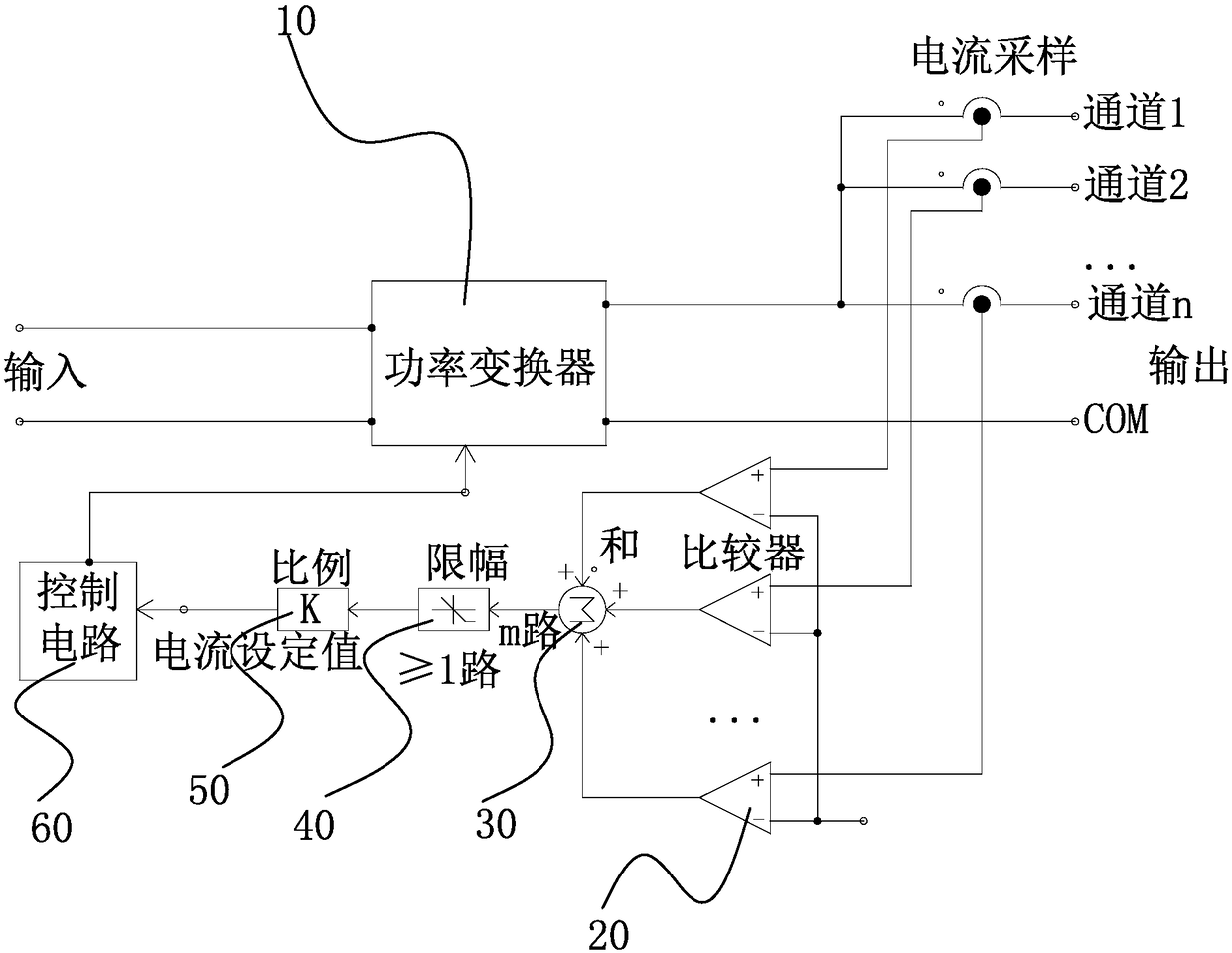

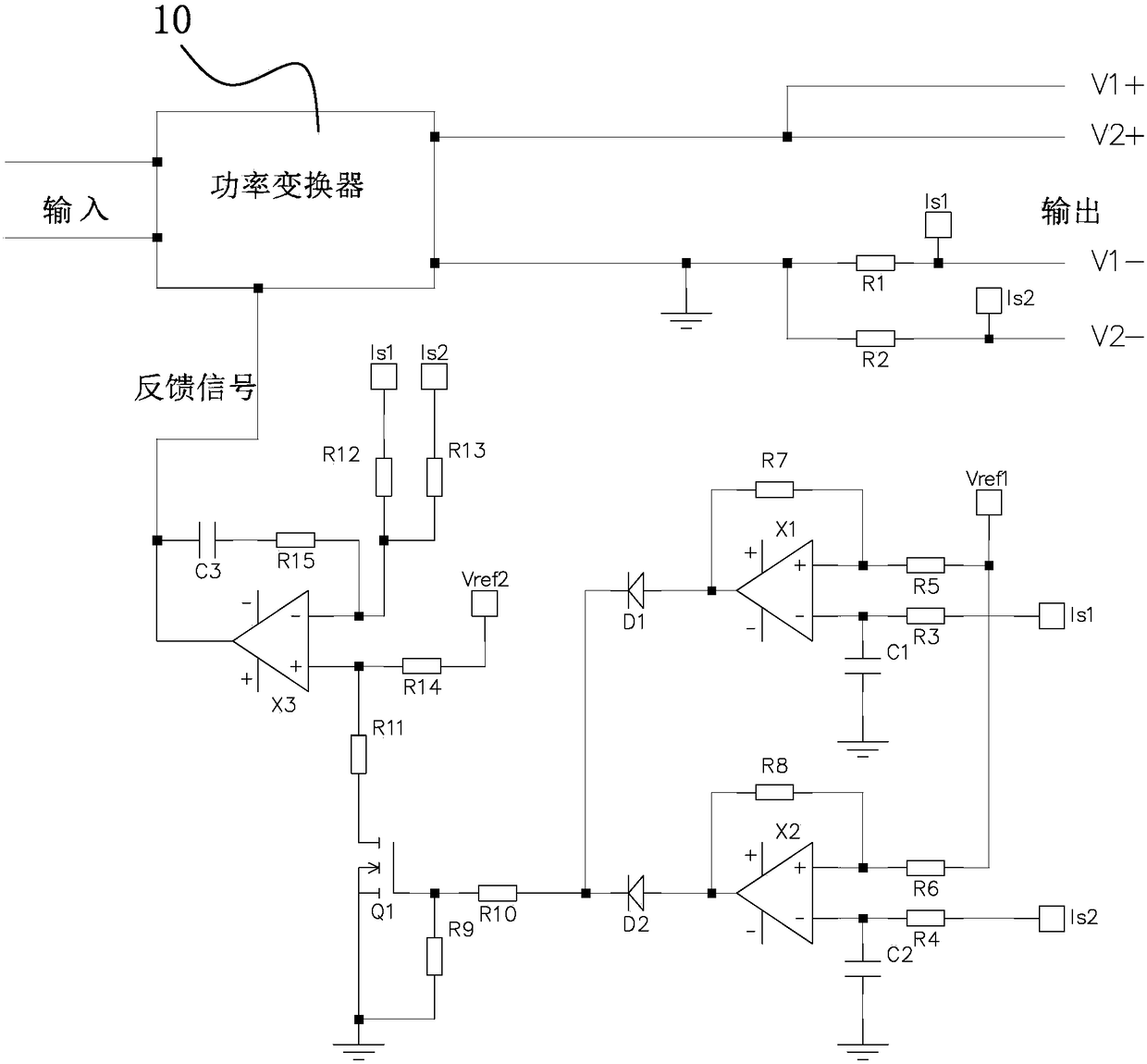

[0030] Such as Figure 1~2 In the specific embodiment shown, the power supply circuit that automatically matches the number of parallel load groups provided in this embodiment can be used in the power supply circuit of a product, such as a charging circuit with multiple output groups, to automatically match the number of parallel load groups and reduce production costs. .

[0031] The power supply circuit that automatically matches the number of parallel load groups includes a current sampling circuit, a load feedback circuit, and a power converter 10. The power converter 10 has multiple load output terminals, and the current sampling circuit is used to collect the output of the power converter 10 The current signal is used as th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com