Clamp for wedge-shaped workpieces

A wedge-shaped tool and fixture technology, which is applied in the direction of workpiece clamping devices, manufacturing tools, etc., can solve problems such as inability to clamp firmly, and achieve the effect of easy installation and fast clamping operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0014] The present invention will be described in further detail below by means of specific embodiments:

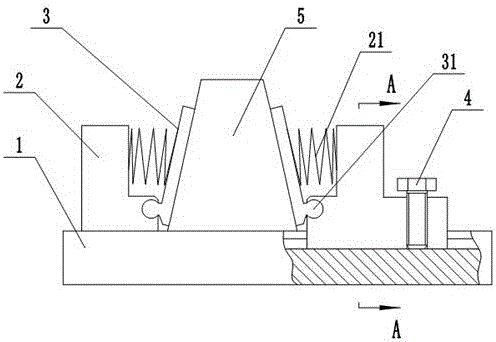

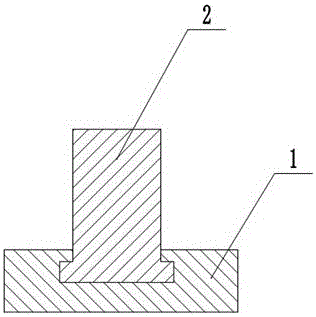

[0015] The reference signs in the accompanying drawings of the specification include: base 1 , pliers body 2 , spring 21 , clamping plate 3 , arc convex rib 31 , locking screw 4 , workpiece 5 .

[0016] The embodiment is basically as attached figure 1 And attached figure 2 Shown:

[0017] The wedge-shaped workpiece fixture in this program includes a base 1 installed on the working platform, and two pliers 2 connected to the base 1, wherein the pliers 2 on the left are welded on the base 1, and the pliers on the right 2 is slidably connected to the base 1, and the clamping plate 3 is rotatably connected to the pliers body 2.

[0018] The specific method of sliding connection between the right pliers body 2 and the base 1 is as follows: a chute is processed on the base 1, and the cross section of the chute is in a convex shape; corresponding bumps. The cross-section o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com