Electric frequency heating dispensing sewing device

A heating point and sewing technology, applied in the field of garment processing machinery, can solve the problems of complicated operation, prone to machine problems, complicated transmission structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

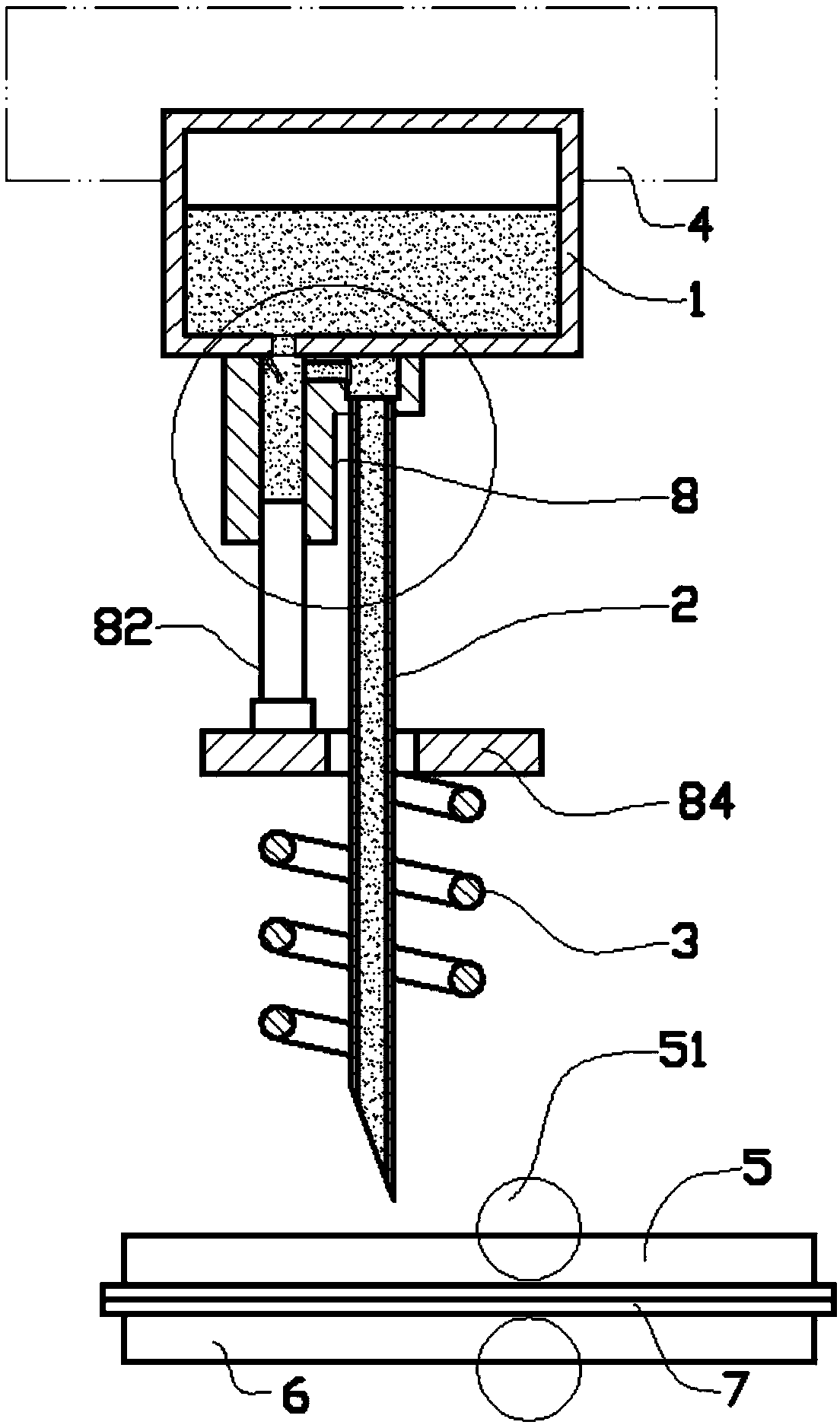

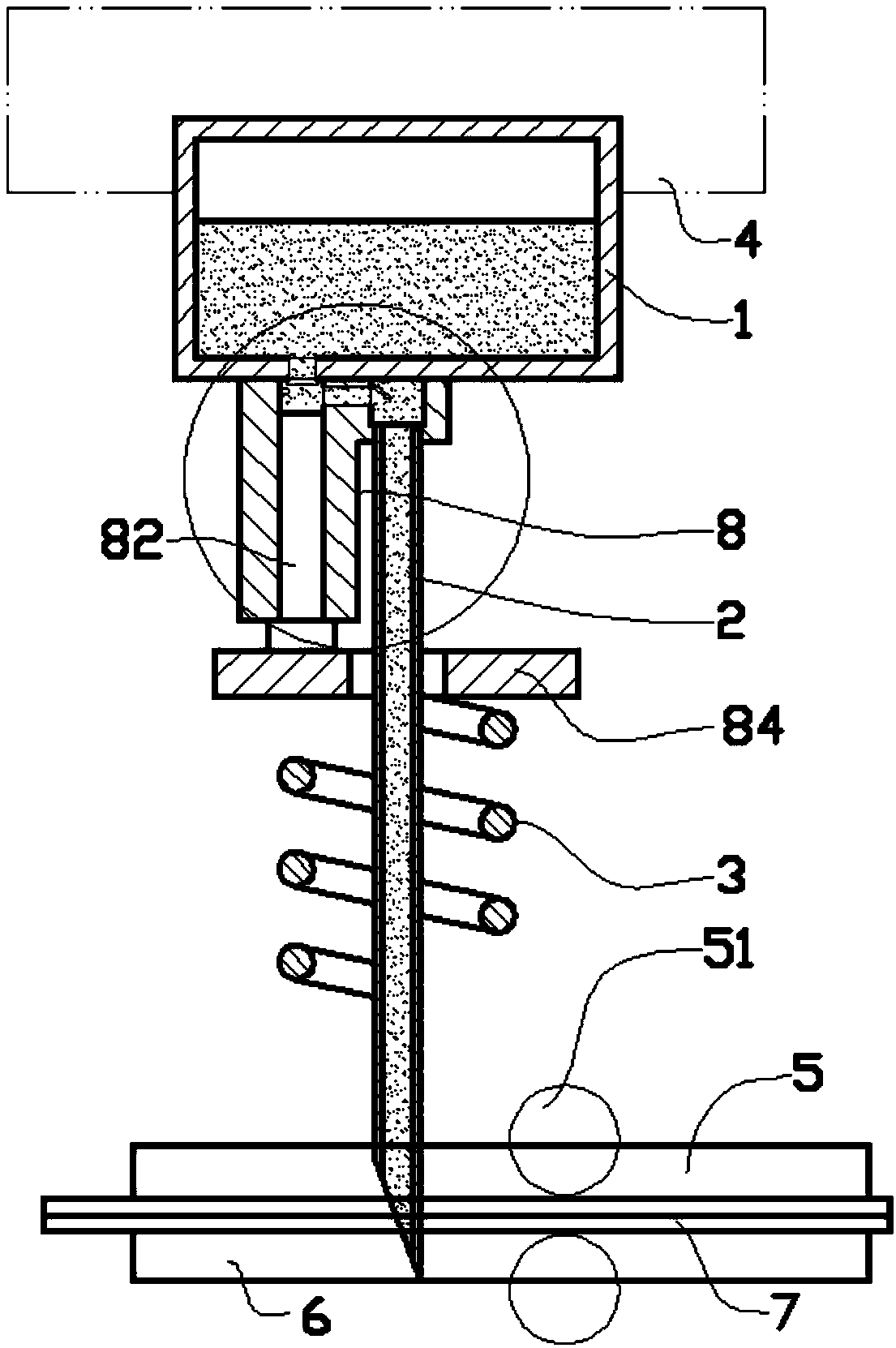

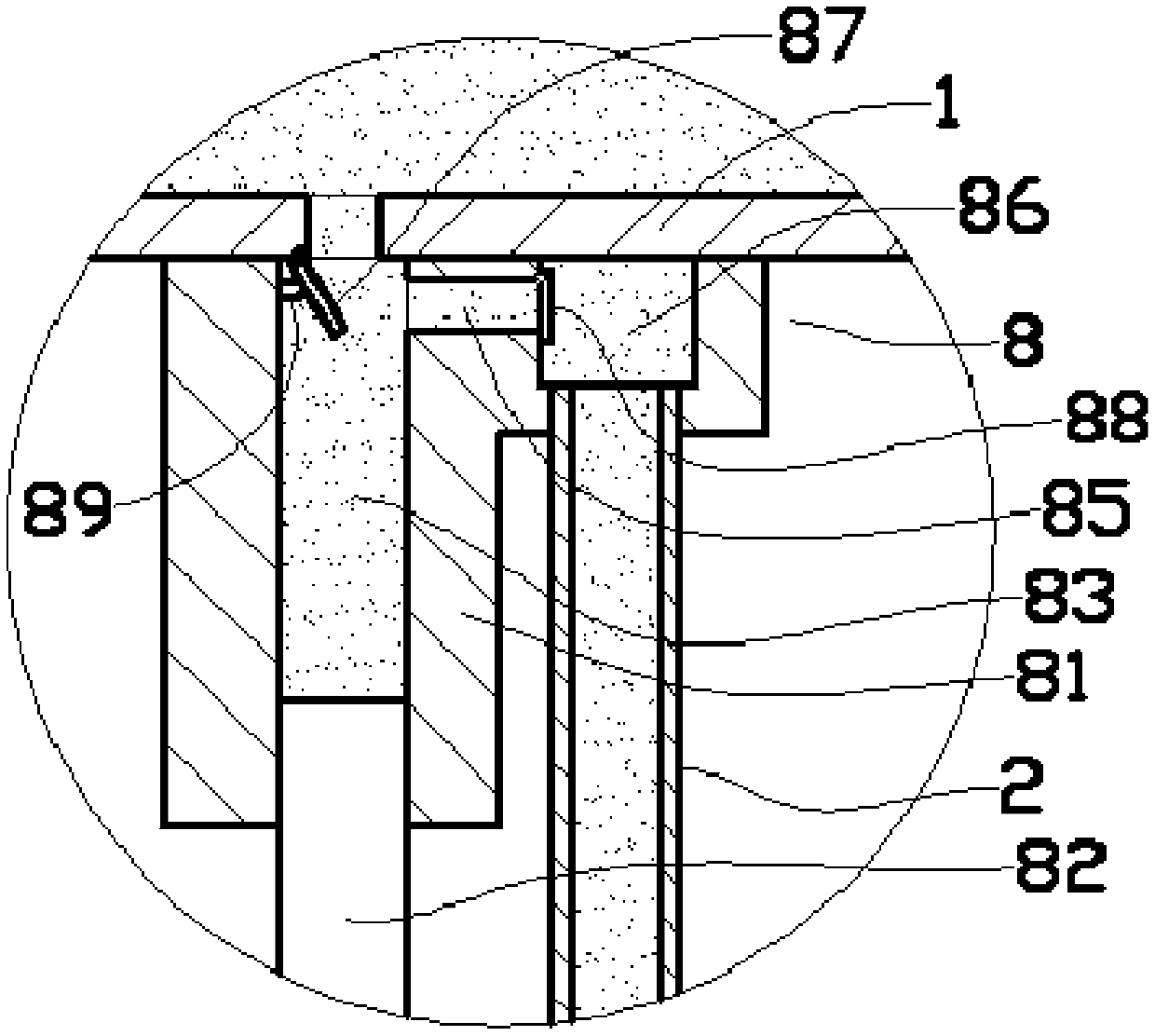

[0016] Such as figure 1 , figure 2 and image 3 , Figure 4 As shown in the embodiment, the electric frequency heating dispensing sewing device includes a glue tank 1 and a sewing needle tube 2. The glue tank 1 is fixedly mounted on the lower part of the sewing machine head 4 that moves up and down, and the sewing needle tube 2 is placed vertically. The bottom of the sewing needle tube 2 is equipped with feed dogs 5 used in pairs, the bottom of the feed dogs 5 is fixed on the sewing table 6, and the fabric 7 to be sewed is placed between the upper and lower feed dogs 5; the sewing A vertical cavity is processed in the middle of the needle tube 2, and an inclined needle point is processed on the lower part of the sewing needle tube 2. The sewing needle tube 2 communicates with the sewing needle tube 2 through a one-way module 8, and the one-way module 8 is asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com