Filtering and mixing integrated ultra-large type screen changing device

A super-large and integrated technology, which is applied in the field of filter devices, can solve the problems of large filter area of screen changer devices, lower material quality, and easy overheating degradation of materials, so as to avoid material retention, improve emission efficiency, and facilitate heat transfer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with embodiment (accompanying drawing):

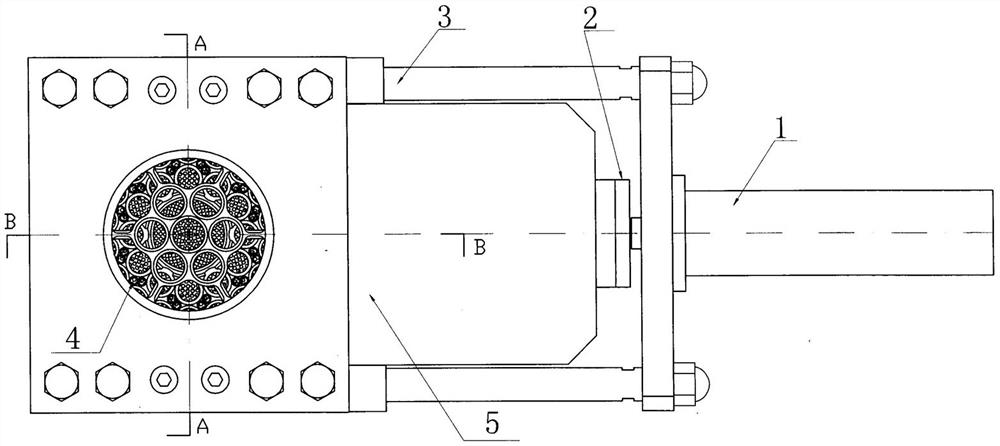

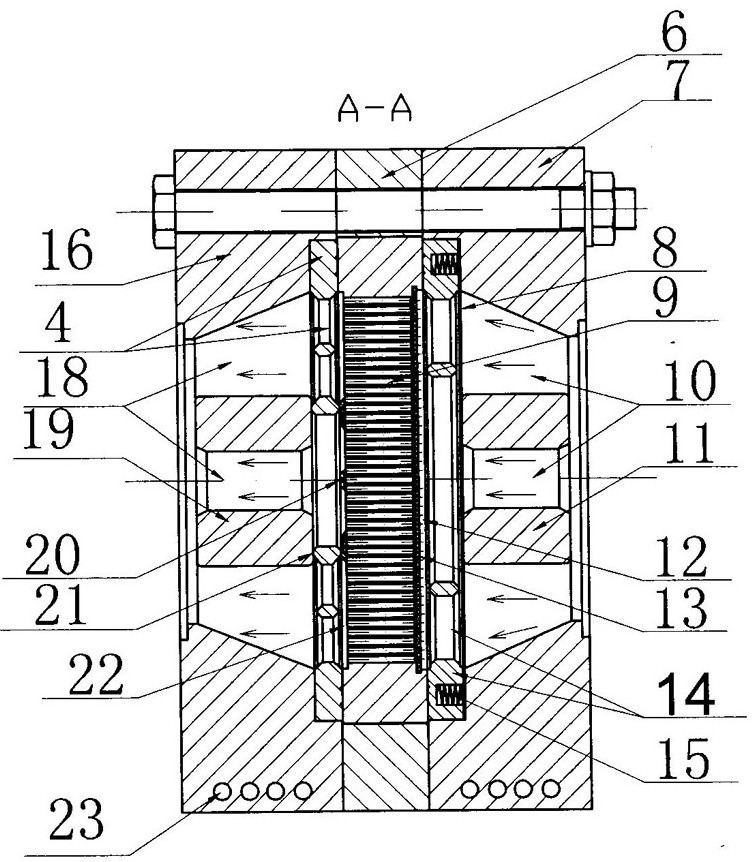

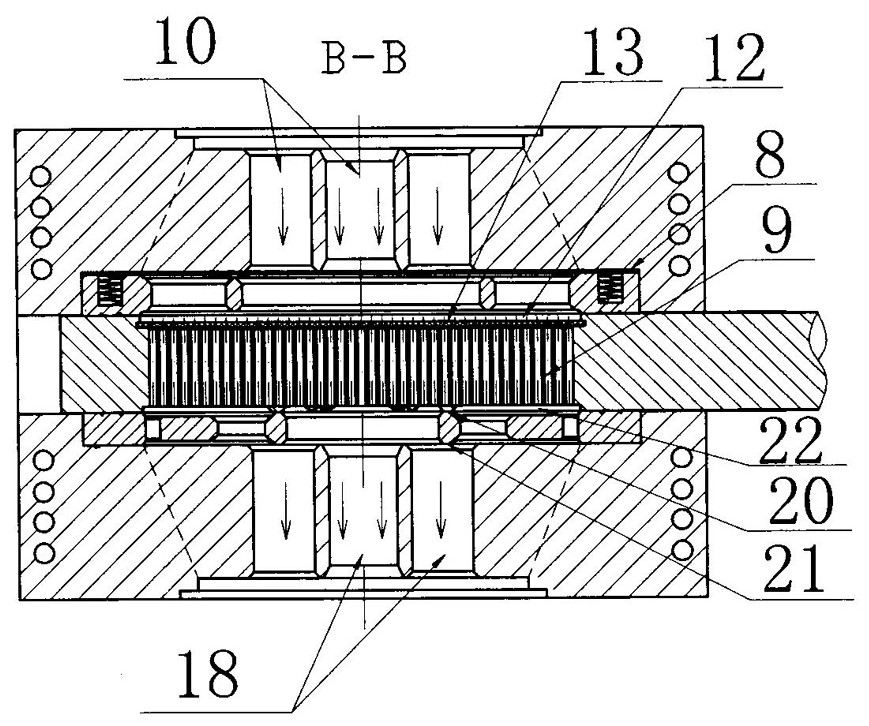

[0032] The filter-mixing integrated ultra-large screen changing device of the present invention includes an outer shell composed of an inlet plate 7, an outlet plate 16, and a gasket 6 clamped between the upper and lower ends of the inlet plate and the outlet plate, and is mounted on the outlet plate, the inlet plate, and the outer shell. The slide plate filter unit 5 in the slideway formed by the board and the upper and lower pads is used to drive the slide plate filter unit to reciprocate along the slideway, and the power mechanism is connected to one side of the slide plate filter unit through the connecting block; There is a material channel and an integrated porous plate 9 on the top, and a filter mesh 13 is provided on the feed side of the integrated porous plate; a hollow structure is provided in the middle part between the inlet plate 7 and the mating su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com