A multi-port blowing structure and blowing method based on small-scale blowing area

A small-scale, filling and filling pipeline technology, applied in the direction of filling water and building land, etc., can solve the problems of reducing the production efficiency of ships, limited radiation area of nozzles, and increased loss of filling and filling, and achieves solutions to ship stagnation, simple structure, and low The effect of churn

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

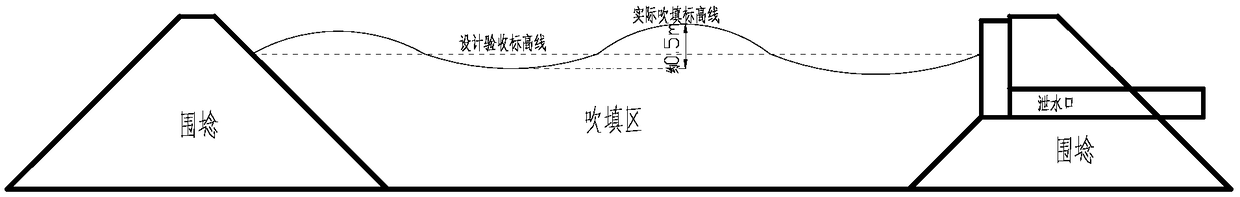

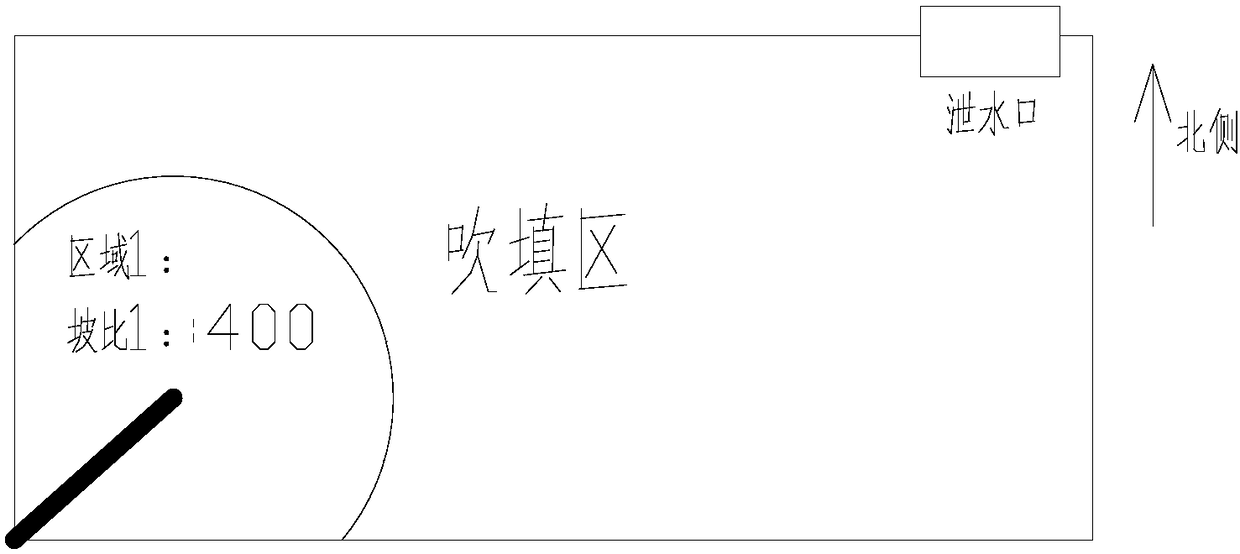

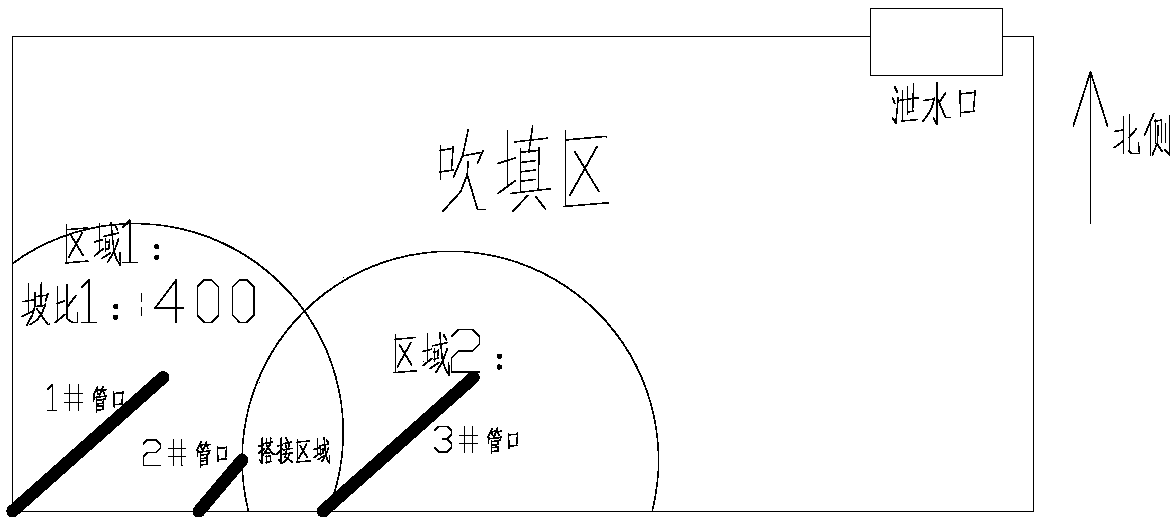

[0029] In order to further understand the invention content, characteristics and effects of the present invention, hereby take the construction of the second phase of earthwork dredging and filling in the second phase of construction of the second phase of earthwork dredging and filling in the starting area of Lingang Industrial Zone, Dongying Economic and Technological Development Zone as an example, and cooperate with the attached The diagram is detailed as follows:

[0030] A multi-port blow-fill structure based on a small-scale blow-fill area, including a blow-fill pipeline 10 laid in the blow-fill area, main blow pipe ports 1 are arranged at intervals on the blow-fill line, and installed on the blow-fill pipeline and the main blow pipe port respectively There is a main ram 2, an auxiliary blowing nozzle 3 is provided between the above-mentioned adjacent main blowing nozzles, and auxiliary rams 4 are respectively installed on the blow-fill pipeline and the auxiliary blowi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com