Ammonia escape in situ laser detection device

A technology of laser detection and ammonia escape, which is applied in measurement devices, material analysis by optical means, instruments, etc., can solve the problems of insufficient measurement accuracy, increased maintenance, and inaccurate laser beams, so as to solve the problem of flue gas stagnation. , Improve fluidity, increase the effect of optical path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

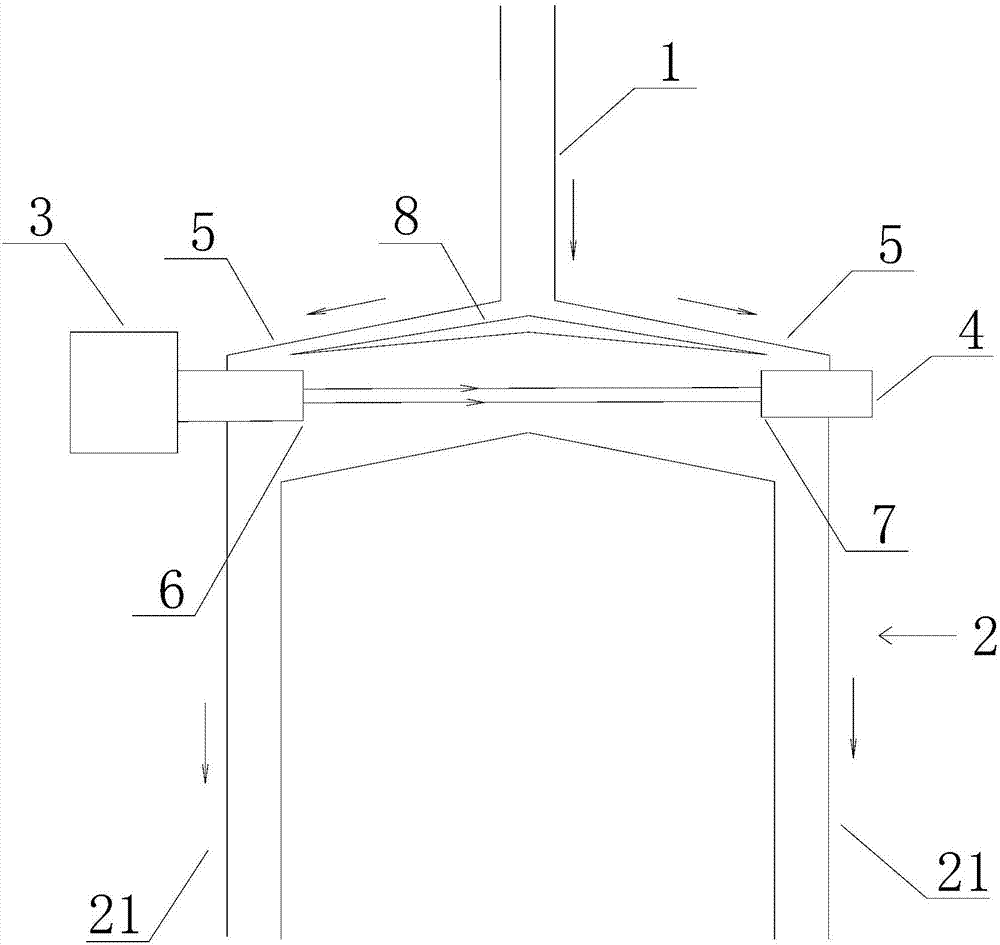

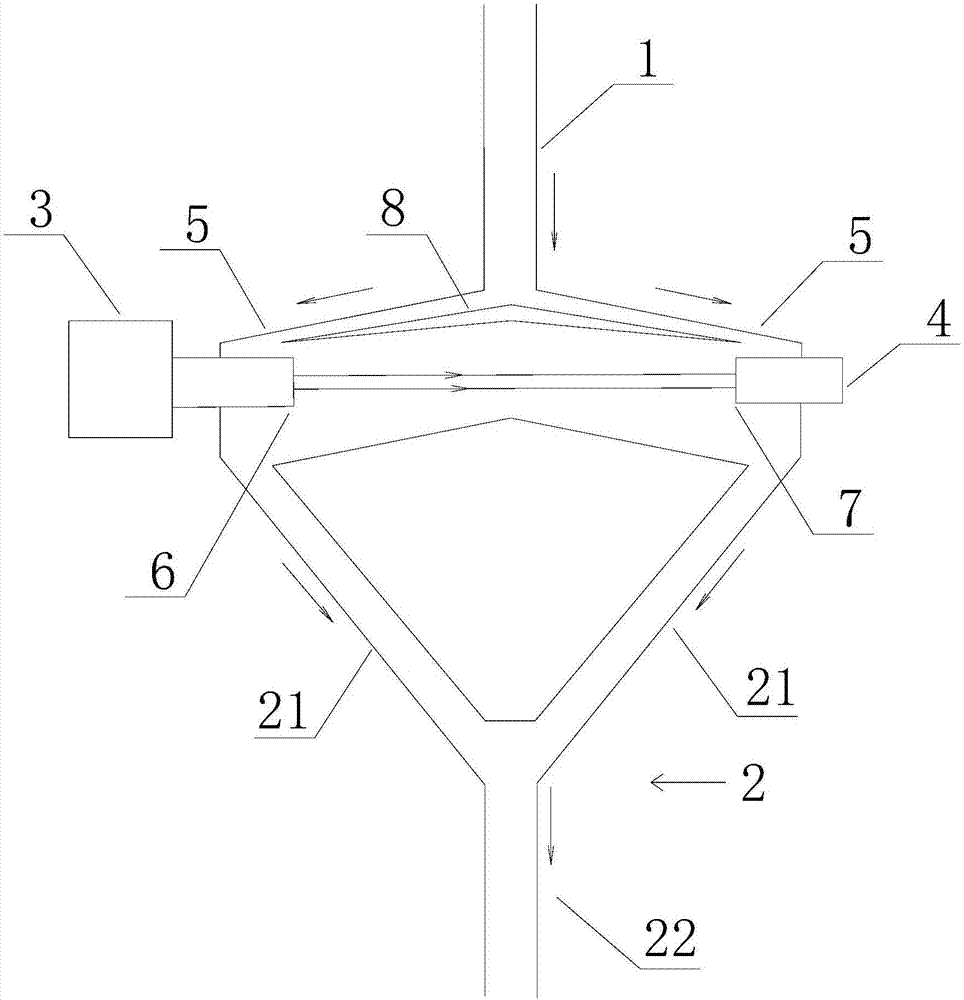

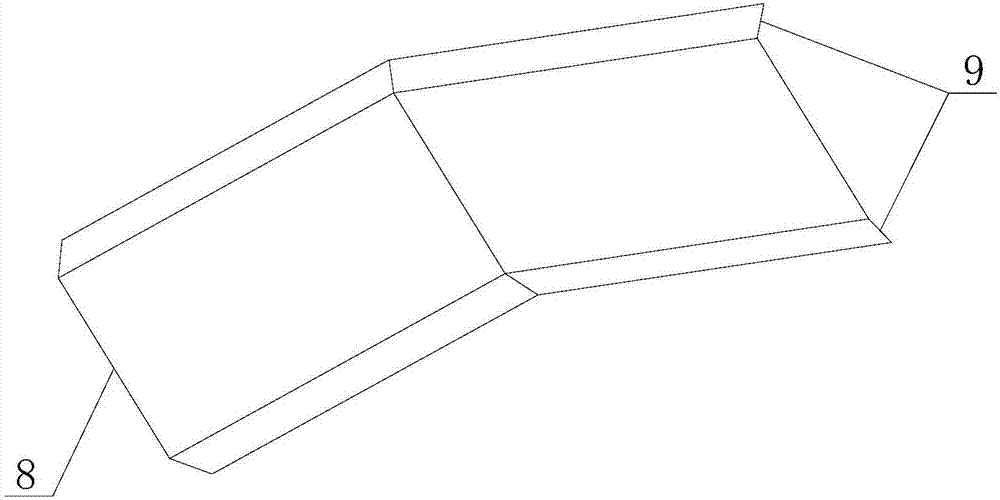

[0029] The present invention will be described in detail below in conjunction with accompanying drawing, as figure 1 As shown: the ammonia escape in-situ laser detection device of this embodiment includes an air inlet pipe 1, an air outlet pipe 2, a laser emitting unit 3 and a laser receiving unit 4, and the air outlet of the air inlet pipe is connected with two left and right branches Pipeline 5, the air inlet pipe is in an inverted Y shape after being communicated with two branch pipes; the air outlet of the two branch pipes is communicated with the air outlet pipe; the air outlet pipe includes two air outlet sub-pipes 21, the two The gas outlet sub-pipes are respectively connected to the two branch pipes; the laser emitting unit and the laser receiving unit are respectively arranged at the ends of the left and right branch pipes, and the emitting area 6 of the laser emitting unit is in the same direction as the receiving area 7 of the laser receiving unit. To relative.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com