Bending machine

A technology for press brakes and beams, applied in the field of press brakes, can solve the problems of expensive structures, costly assembly of press beams or their components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

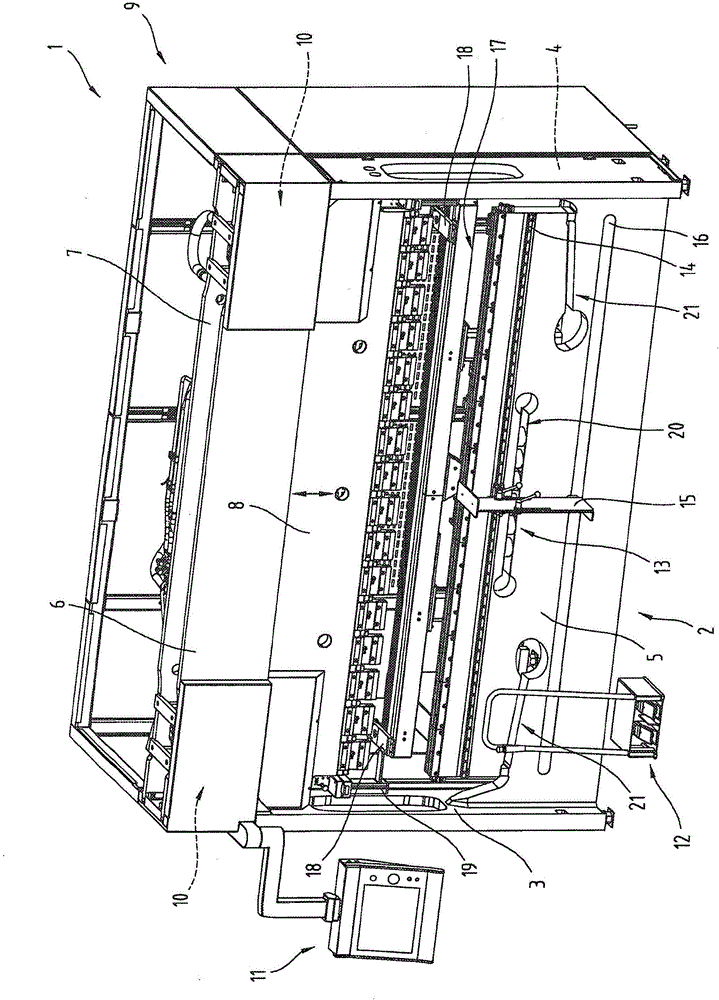

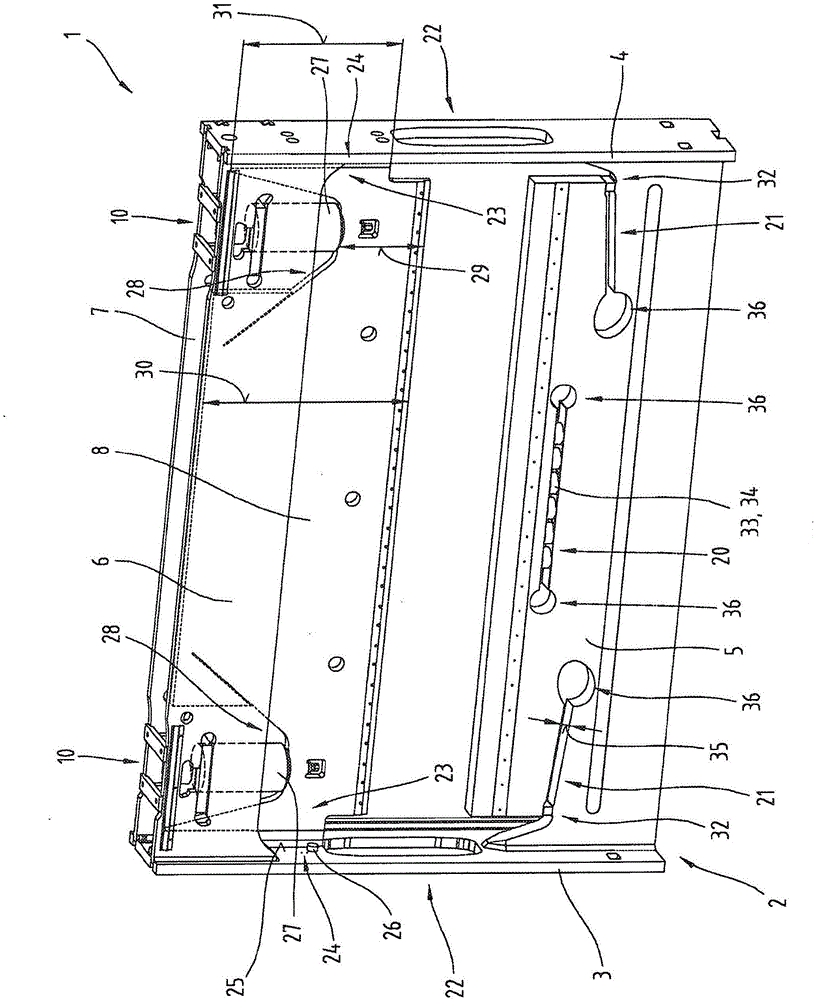

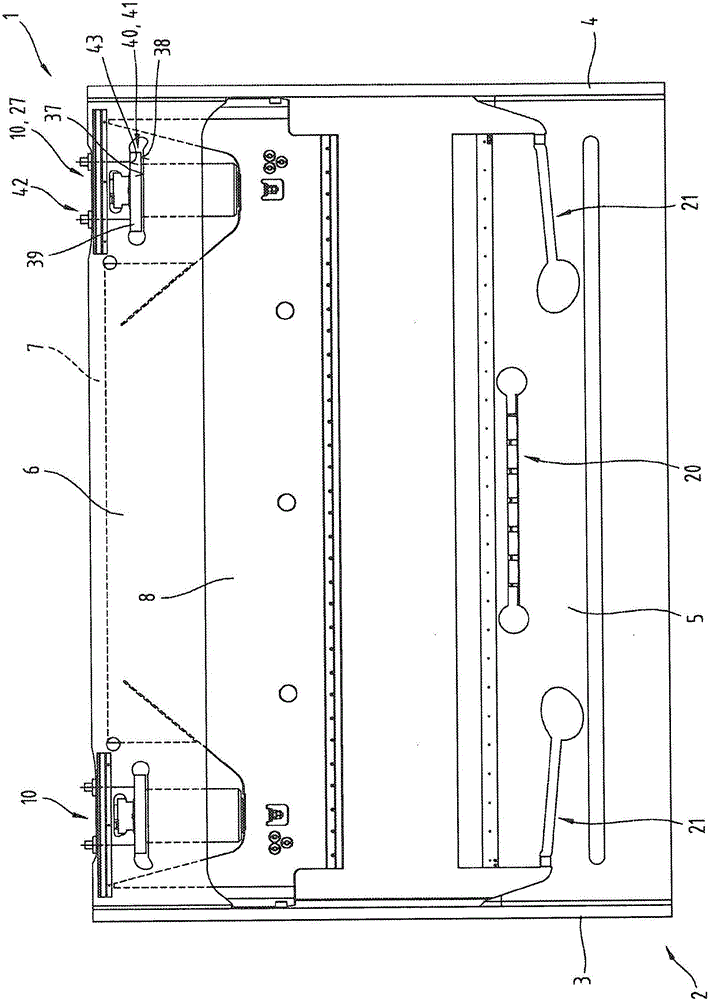

[0034] exist Figures 1 to 5 A possible embodiment of the press brake 1 according to the invention is shown in , in which certain shown structural features are not to be regarded as mandatory features for the invention, but rather alone or in combination with other structural features In combination, a possible embodiment according to the invention of the press brake 1 can be formed.

[0035] figure 1 A press brake 1 in the form of an edge bender according to the invention is shown in oblique view from the front side on the operator's side. Here, the press brake 1 comprises a machine frame 2 with two sides 3 and 4 spaced apart from each other, which are passed through a fixed lower pressure beam 5 and two fixed upper cross members. 6 and 7 are fixedly connected to each other and thus basically form a fixed part of the machine frame 2 . In the machine frame 2, an upper pressing beam 8 is mounted adjustable and cooperating bending tools, not shown in the figures, can be arran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap