Flexible LED lamp assembly

A technology of light assembly and axis, applied in the direction of headlights, vehicle parts, lighting and heating equipment, etc., can solve problems such as low light efficiency and poor beam pattern distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

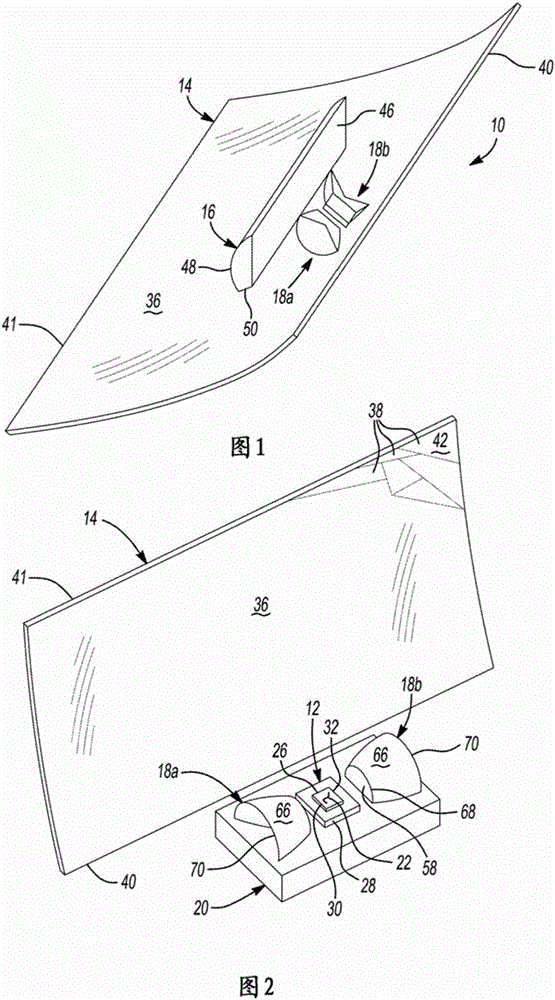

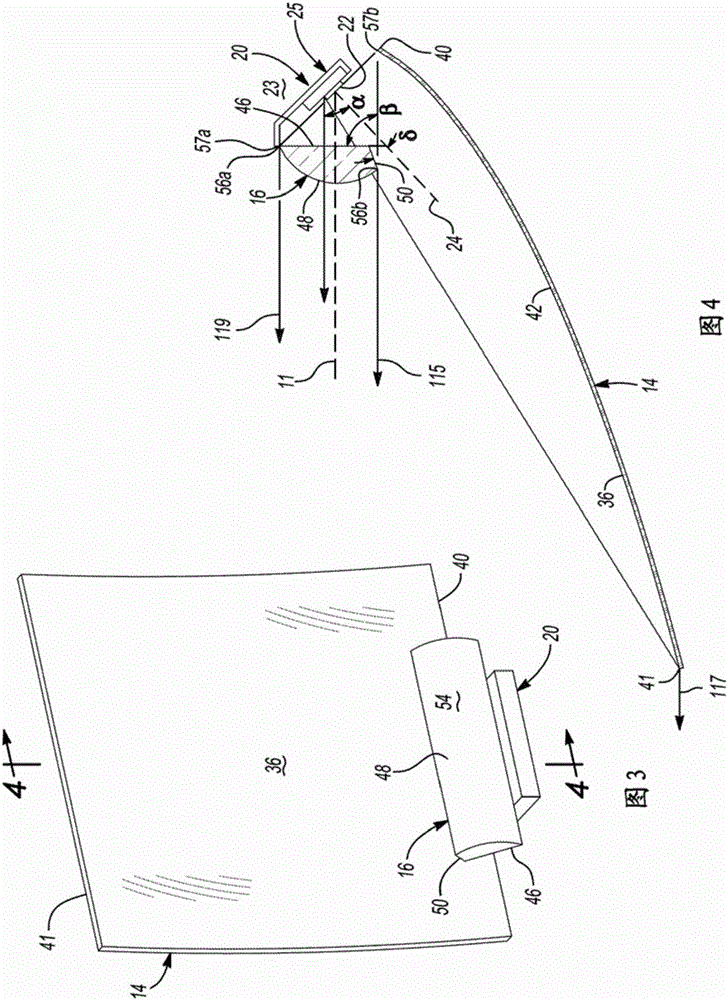

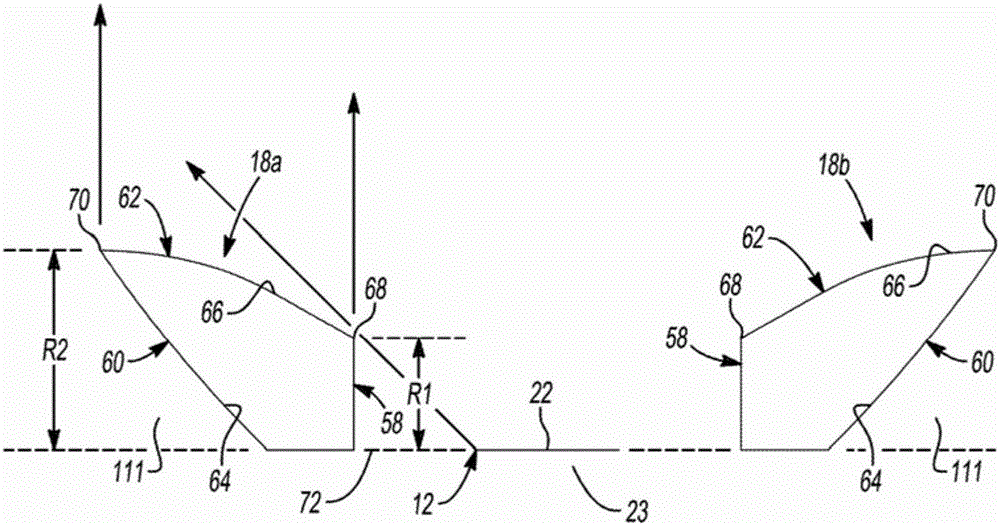

[0025] Exemplary embodiments will now be described more fully with reference to the accompanying drawings.

[0026] refer to figure 1 , provides a lamp assembly 10, the lamp assembly 10 may include a light source or light emitting device 12, a reflector 14, a lens 16, a first light collector 18a and a second light collector 18b. as in Figure 4 As illustrated in , the lamp assembly 10 may be used to project light in a forward direction along an optical axis 11 . In the exemplary embodiment, light assembly 10 is a fog light for use in an automobile or other motor vehicle. In other embodiments, the light assembly 10 may be a headlight assembly having a high beam light projection portion and a low beam light projection portion (not shown).

[0027] In the exemplary embodiment, light emitting device 12 is a light emitting diode. In other embodiments, the lighting device 12 may be another flat, Lambertion lighting device. In one configuration, the lighting device 12 is secured...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap